What Are Advantages Of Flexible Manufacturing System Fms

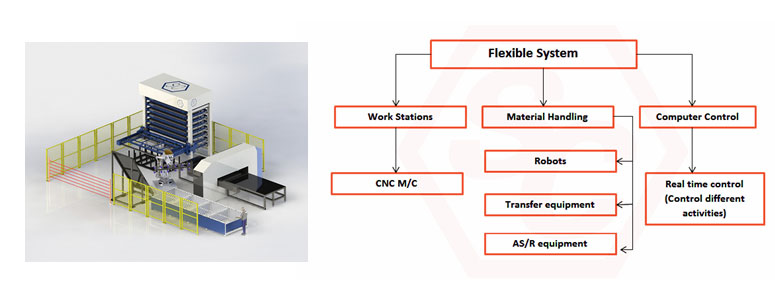

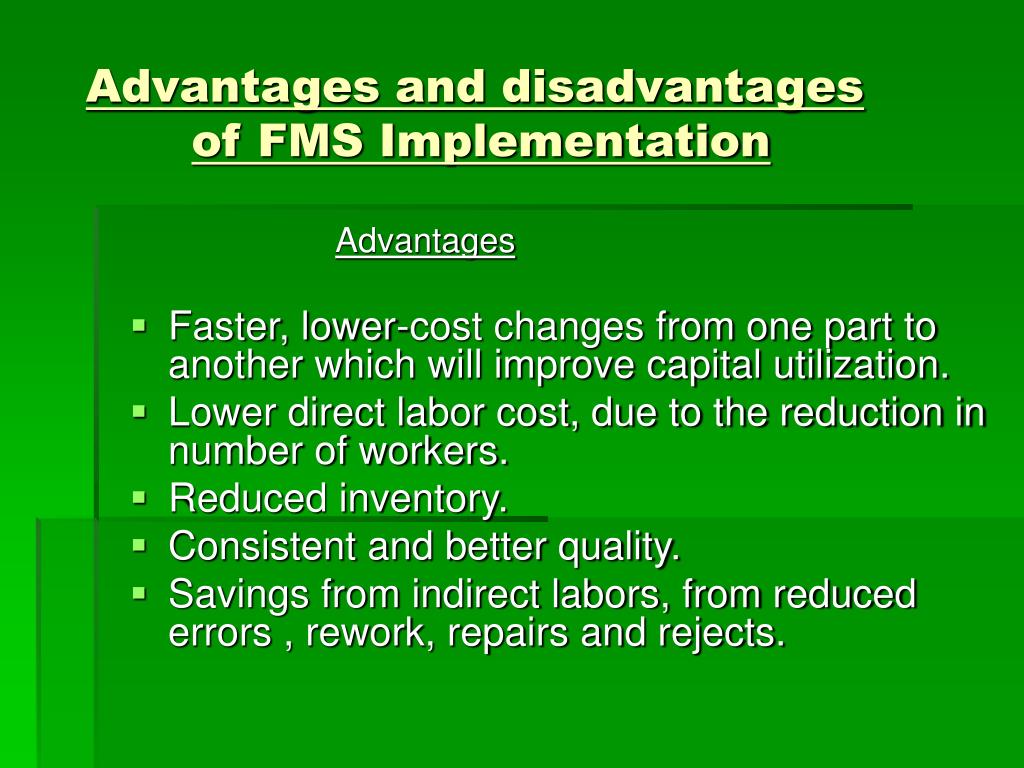

What Are Advantages Of Flexible Manufacturing System Fms A flexible manufacturing system (fms) is the production method that helps make this happen, and it can cut down both on production times and the amount of resource required. the system is designed to adapt to changes like slight (or more significant) variations to a product, production volumes – or even the addition of entirely new products. The core components of fms. at its essence, a flexible manufacturing system comprises interconnected machines, robots, and computer systems working in tandem. these components communicate and adapt in real time to produce diverse product types without the need for extensive reprogramming or reconfiguration. 3.

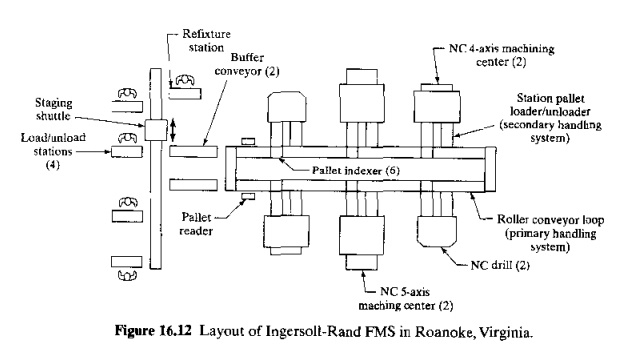

Flexible Manufacturing Systems Fms Applications And Benefits A flexible manufacturing system (fms) is a method of production that prioritizes adaptability. it's a recognition of change as an inevitable part of manufacturing operations, both big and small. fms is designed to accommodate production changes without affecting the quality, budget, or production deadlines. 1. flexible manufacturing units. flexible manufacturing units (fmc) consist of 1 2 machining centers, industrial robots, cnc machine tools, and material transportation and storage equipment. they are adaptable and flexible for machining diverse products. an fmc can be considered as the smallest scale fms and represents the evolution of fms. A flexible manufacturing system (fms) is a production method that is designed to easily adapt to changes in the type and quantity of the product being manufactured. machines and computerized. A flexible manufacturing system (fms) is a computer controlled production setup designed primarily to adapt at any time to changes such as product details, new products, batch sizes, sequence reordering, and so on. an fms relies on automation as much as possible using advanced technology and flexible manufacturing software, resulting in higher.

Flexible Manufacturing System Definition Advantage Shenchong A flexible manufacturing system (fms) is a production method that is designed to easily adapt to changes in the type and quantity of the product being manufactured. machines and computerized. A flexible manufacturing system (fms) is a computer controlled production setup designed primarily to adapt at any time to changes such as product details, new products, batch sizes, sequence reordering, and so on. an fms relies on automation as much as possible using advanced technology and flexible manufacturing software, resulting in higher. Flexible manufacturing systems (fms) are designed to allow manufacturers to make sudden changes to production plans. in contrast with mass production on a traditional production line, the goal is easy adaptation of a manufacturing process at any time. this can range from producing brand new products to modifying batch sizes to simply reordering. A flexible manufacturing system (fms) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. this flexibility is generally considered to fall into two categories, which both contain numerous subcategories. the first category is called routing.

Ppt Flexible Manufacturing Systems Fms Powerpoint Presentation Flexible manufacturing systems (fms) are designed to allow manufacturers to make sudden changes to production plans. in contrast with mass production on a traditional production line, the goal is easy adaptation of a manufacturing process at any time. this can range from producing brand new products to modifying batch sizes to simply reordering. A flexible manufacturing system (fms) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. this flexibility is generally considered to fall into two categories, which both contain numerous subcategories. the first category is called routing.

Comments are closed.