Welding Thin Sheet Metal Mig Vs Tig Youtube

Welding Thin Sheet Metal Mig Vs Tig Youtube I get asked a lot of questions about mig welding and tig welding and so i decided to make a comparison video showing the pros and cons of both welding method. On this episode of make it kustom, i'm back on the model a roadster welding on the hood and shaving the cowl using both mig welding and tig welding technique.

Mig Versus Tig Welding On Car Bodywork Thin Sheet Steel Vs Fuse the thick side without burning through the thin using these techniques for gas metal arc welding (gmaw), gas tungsten arc welding (gtaw) or shielded met. Mig welding sheet metal. when welding thin metal, the main objective is to avoid warping, burn through and excessive heat affected zones while still ensuring the weld has enough mechanical strength for the application. short circuit transfer mig (short arc), tig and pulsed tig welding processes provide the most control over the heat to address. To weld thin stock successfully, use a small diameter tungsten electrode like 0.020, 0.040, and 1 16 in. large diameter tungsten electrodes require higher amperage to start the arc, leading to warping or burning of the material. grind the tungsten tip to a sharp point to weld steel, and use either er70s 2 filler metal or a silicon bronze rod. Tig v. mig welding – a comparison checklist. material thickness: tig welding: ideal for welding thin materials (less than 1 8 inch). mig welding: suited for thicker materials (1 8 inch and above). weld quality: tig welding: provides exceptional weld quality and precise control, resulting in clean and aesthetically pleasing welds.

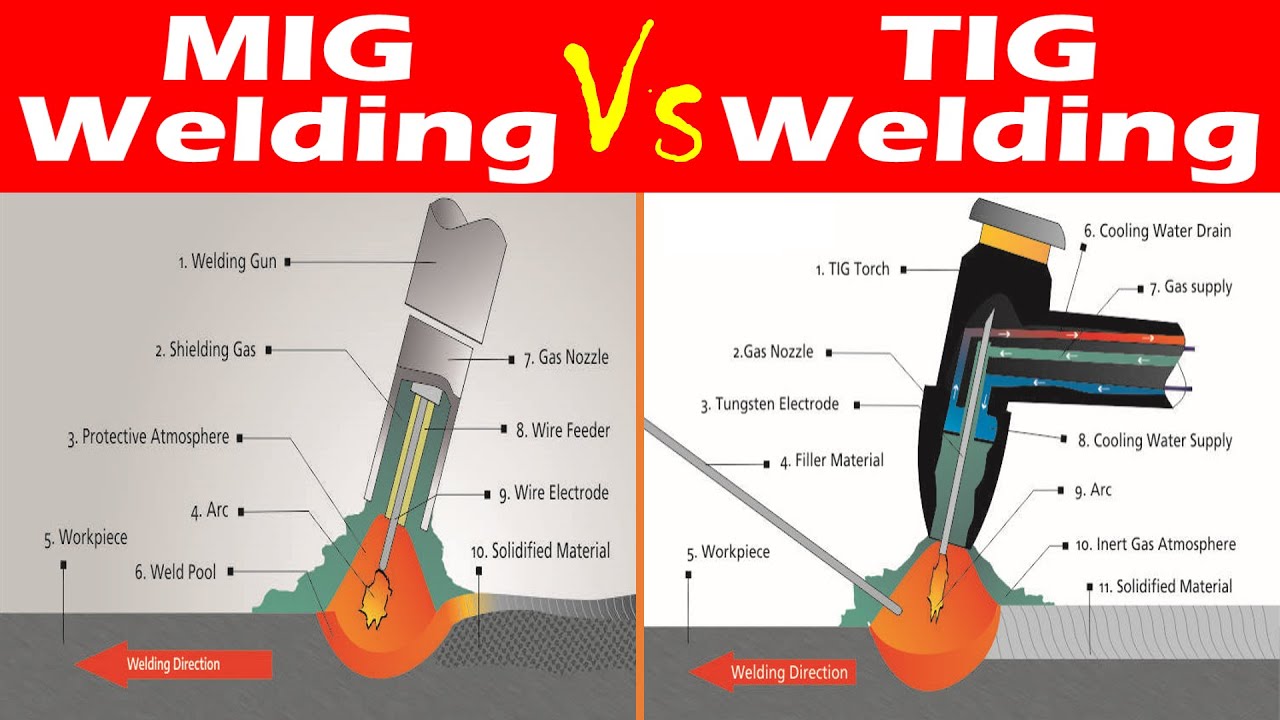

Differences Between Mig Welding And Tig Welding Youtube To weld thin stock successfully, use a small diameter tungsten electrode like 0.020, 0.040, and 1 16 in. large diameter tungsten electrodes require higher amperage to start the arc, leading to warping or burning of the material. grind the tungsten tip to a sharp point to weld steel, and use either er70s 2 filler metal or a silicon bronze rod. Tig v. mig welding – a comparison checklist. material thickness: tig welding: ideal for welding thin materials (less than 1 8 inch). mig welding: suited for thicker materials (1 8 inch and above). weld quality: tig welding: provides exceptional weld quality and precise control, resulting in clean and aesthetically pleasing welds. The difference between tig (tungsten inert gas) and mig (metal inert gas) welding is that tig welding uses a tungsten metal rod to fuse two metals directly together, while mig welding uses a feed wire through a spool gun to weld two metals together. you’ll need to know a bit more about how these processes work and what their strengths and. Mig welding is the most common technique welders use for thin metals. here are the steps you need to take for this process. 1. choose the right shielding gas. mig welding works in tandem with the shielding gas, which prevents the weld from oxidizing. the shielding gas also affects the weld bead’s appearance.

How To Mig Weld Butt Welding Thin Sheet Metal Gap Or No Gap Y The difference between tig (tungsten inert gas) and mig (metal inert gas) welding is that tig welding uses a tungsten metal rod to fuse two metals directly together, while mig welding uses a feed wire through a spool gun to weld two metals together. you’ll need to know a bit more about how these processes work and what their strengths and. Mig welding is the most common technique welders use for thin metals. here are the steps you need to take for this process. 1. choose the right shielding gas. mig welding works in tandem with the shielding gas, which prevents the weld from oxidizing. the shielding gas also affects the weld bead’s appearance.

Comments are closed.