Video 5 Cost Saving Design Tips For Cnc Machining Xometry

Video 5 Cost Saving Design Tips For Cnc Machining Xometry Design tip #5: part marking. adding part marking is a great way to identify a part and its revision. we recommend using engraving, which can be done during machining operations, wherever possible. sans serif text works best in at least a 20 point font size. avoid raised or embossed markings whenever possible because we have the machine around. In this video xometry's director of application engineering, greg paulsen, presents five expert tips for cutting costs when designing custom cnc machined par.

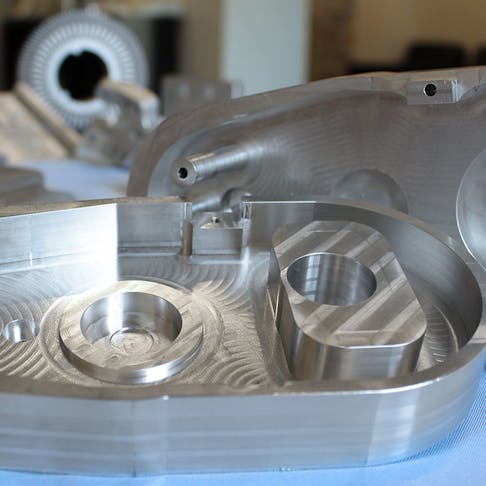

Video 5 Cost Saving Design Tips For Cnc Machining Xometry Xometry's machine learning. 5 cost saving design tips for cnc machining. video: 10 tips to improve your cad designs for cnc machining. Adjusting your design to standard machining tools ; thinking about work holding when making a design; features that are hard and expensive to manufacture; how tolerances impact the cost of parts; top tips for tapped and threaded holes; material finishes and post processing selection; proper 3d models for faster machining setup. Follow our design tips and guidelines in the succinct infographic for more ways to save money and manufacturing time on your custom cnc machined components. about xometry xometry offers instant pricing for manufacturing, including precision cnc machining, 3d printing, sheet metal fabrication, injection molding, and urethane casting services. 8. avoid extremely small features. most cnc machines have a minimum tool diameter of 2.5 mm, meaning any feature smaller than 2.5 mm would be difficult to machine and would require special tools, which increases machining costs and time. 9. design holes with standard sizes.

Design Guide For Cnc Machining Xometry Europe Follow our design tips and guidelines in the succinct infographic for more ways to save money and manufacturing time on your custom cnc machined components. about xometry xometry offers instant pricing for manufacturing, including precision cnc machining, 3d printing, sheet metal fabrication, injection molding, and urethane casting services. 8. avoid extremely small features. most cnc machines have a minimum tool diameter of 2.5 mm, meaning any feature smaller than 2.5 mm would be difficult to machine and would require special tools, which increases machining costs and time. 9. design holes with standard sizes. Part design and geometry significantly affect the cost of cnc machining. it is a rule of thumb that the more complex a part is, the more expensive it will be to manufacture. highly complex parts may require more advanced machinery. they also require more machining time, multiple passes and setups, more resources, and closer inspection. 4. expand thin walls. cnc parts with thin walls have a tendency to chatter, which slows down machining speeds. they can also cause distortion, which makes it difficult to hold tolerances. the result can be additional costs. in order to keep machining costs low, thin walls should have a minimum width of 1 32” (0.794mm).

Design Guide For Cnc Machining Xometry Europe Part design and geometry significantly affect the cost of cnc machining. it is a rule of thumb that the more complex a part is, the more expensive it will be to manufacture. highly complex parts may require more advanced machinery. they also require more machining time, multiple passes and setups, more resources, and closer inspection. 4. expand thin walls. cnc parts with thin walls have a tendency to chatter, which slows down machining speeds. they can also cause distortion, which makes it difficult to hold tolerances. the result can be additional costs. in order to keep machining costs low, thin walls should have a minimum width of 1 32” (0.794mm).

Design Tips For Cnc Machining Xometry

Comments are closed.