Upgrades And Optimizations Of Your Haccp Flow Diagrams

Completing Your Haccp Plan Template A Step By Step Guide Safesite Time is now to upgrade your food safety system. this webinar will focus on concluded nonconformities during audits of food safety systems in previous 4 years. Upgrades and optimizations of your flow diagrams posted in food safety fridays: upgrades and optimizations of your flow diagrams taking place: friday, april 20, 2018 03:00 pm 04:00 pm uk time this is a 10.00 am eastern us start presenter: vladimir surčinski, auditor and trainer for food standards, ifsqn webinar overview: time is now to upgrade your food safety system.

.png?width=1920&name=HACCP (6).png)

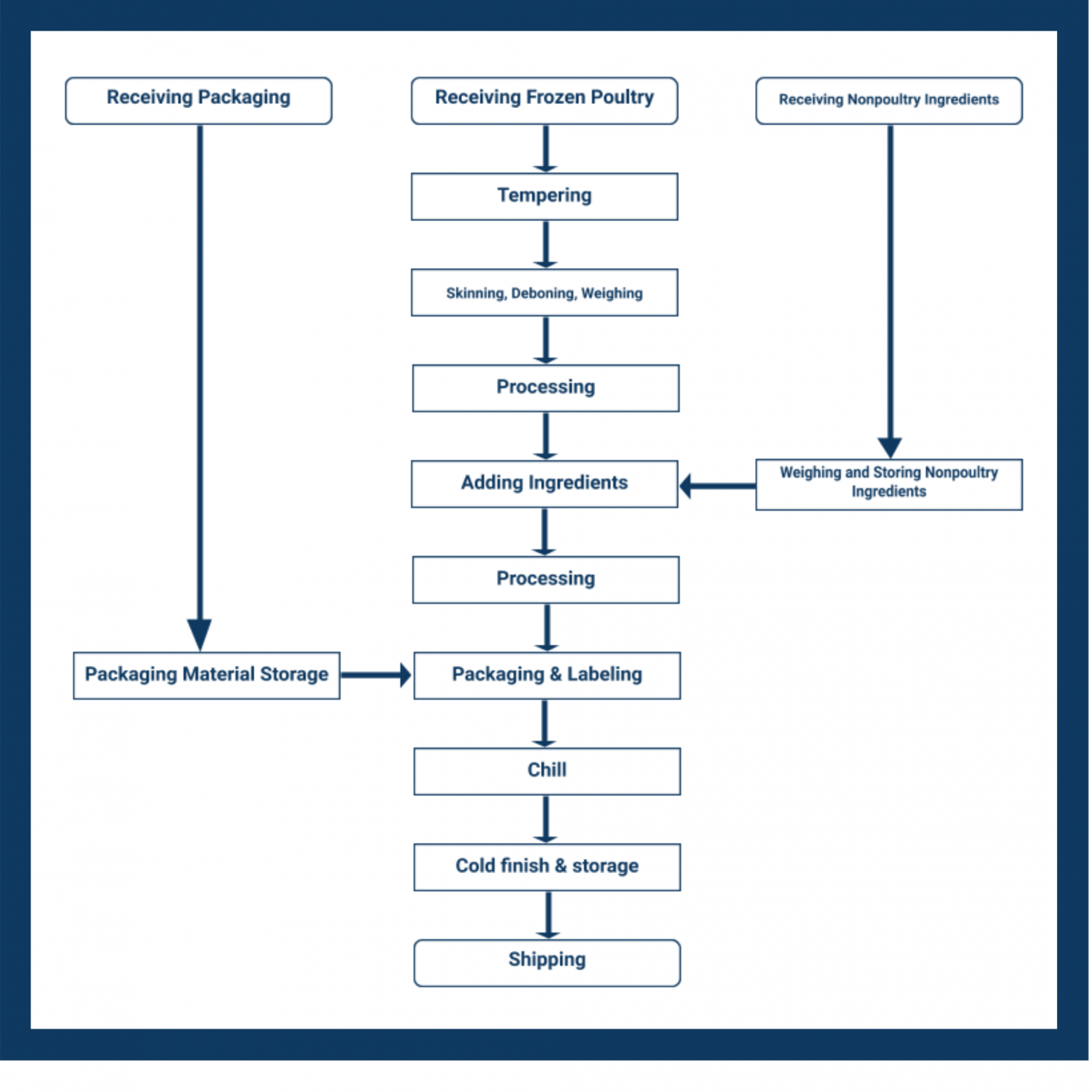

Haccp Guide Definition Templates And The 7 Principles Of Safe Food This guidebook is intended for small and very small establishments. the guidebook clarifies the 9 code of federal regulations (cfr) part 417 hazard analysis and critical control point (haccp) systems requirements and provides guidance on how establishments might develop haccp plans that meet those requirements. Step 5. verify your haccp flow chart. after completing your flow diagram together with the whole haccp plan, you always need to double check if your haccp plan is correct and fits your food manufacturing process perfectly. these key times when you need to revise your flow chart are: at least once a year as an update or to apply revisions. Video: upgrades and optimizations of your haccp flow diagrams. april 23, 2018; 3:36 pm; many in the food industry know the importance of implementing haccp in their. The haccp team should perform an on site review of the operation to verify the accuracy and completeness of the flow diagram. modifications should be made to the flow diagram as necessary and.

Upgrades And Optimizations Of Your Haccp Flow Diagrams Youtube Video: upgrades and optimizations of your haccp flow diagrams. april 23, 2018; 3:36 pm; many in the food industry know the importance of implementing haccp in their. The haccp team should perform an on site review of the operation to verify the accuracy and completeness of the flow diagram. modifications should be made to the flow diagram as necessary and. The steps to developing your haccp plan include: assembling your haccp team; describing your food products and distribution methods; describing the intended use consumers of your product; creating a flow diagram to describing the process; verifying the flow diagram; working through haccp principles 1 7 step by step; 1. assembling the haccp team. The simplest form of process flow diagram is linear. the key steps in the process are identified, laid out step by step, and subsequently verified by the haccp team. the diagram shows a simple 8 step process, where one step follows the next in order: step 1: purchase. step 2: receipt storage. step 3: preparation. step 4: mixing. step 5: cooking.

Haccp Flow Chart The steps to developing your haccp plan include: assembling your haccp team; describing your food products and distribution methods; describing the intended use consumers of your product; creating a flow diagram to describing the process; verifying the flow diagram; working through haccp principles 1 7 step by step; 1. assembling the haccp team. The simplest form of process flow diagram is linear. the key steps in the process are identified, laid out step by step, and subsequently verified by the haccp team. the diagram shows a simple 8 step process, where one step follows the next in order: step 1: purchase. step 2: receipt storage. step 3: preparation. step 4: mixing. step 5: cooking.

Haccp Flow Chart Food Safety Direct

Comments are closed.