Toyota The Five Principles Of 5s Vrogue Co

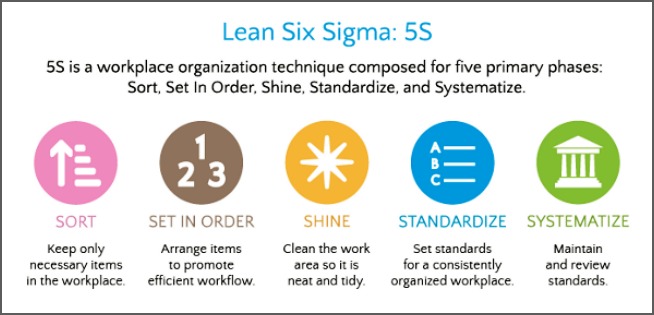

Toyota The Five Principles Of 5s Vrogue Co One way all of our associates stay accountable for these values is through the toyota lean management operational processes, including “5s”. the process of 5s was coined and made popular by toyota. it is based on 5 principles starting with the letter “s”. in japanese, seiri (sort), seiton (systematize), seiso (shine), seiketsu. The toyota way is a set of principles defining the organizational culture of toyota motor corporation. [ 1 ] [ 2 ] the company formalized the toyota way in 2001, after decades of academic research into the toyota production system and its implications for lean manufacturing as a methodology that other organizations could adopt. [ 3 ].

Toyota The Five Principles Of 5s Vrogue Co The discipline is based on five words starting with the letter “s.”. the principles in japanese and english are: seiri (sort) seiton (set in order) seiso (shine) seiketsu (standardize) shitsuke (sustain) the goal of the system is to avoid waste, and it aims to eliminate unnecessary steps and avoidable spending. The concept of 5s. 5s is a methodical way to organize your workplace and your working practices as well as being an overall philosophy and way of working. it is split into 5 phases, each named after a different japanese term beginning with the letter “s”; (seiri, seiton, seiso, seiketsu, shitsuke) hence the name 5 s. The toyota way training 2024 welcome to the toyota way and 5s training program – a comprehensive initiative designed to introduce participants to the world renowned methodologies of the toyota production system and 5s methodology. this training offers a unique opportunity for individuals to delve into the principles of kaizen (continuous improvement), 5s (sort, set in … toyota 5s program. The toyota way is based on two categories with five principles: continuous improvement (challenge, kaizen, genchi genbutsu) and respect for people (respect, teamwork, humility). it provides toyota's philosophy, values, and manufacturing approach. the first principle of challenge is often overlooked but is about working through obstacles to.

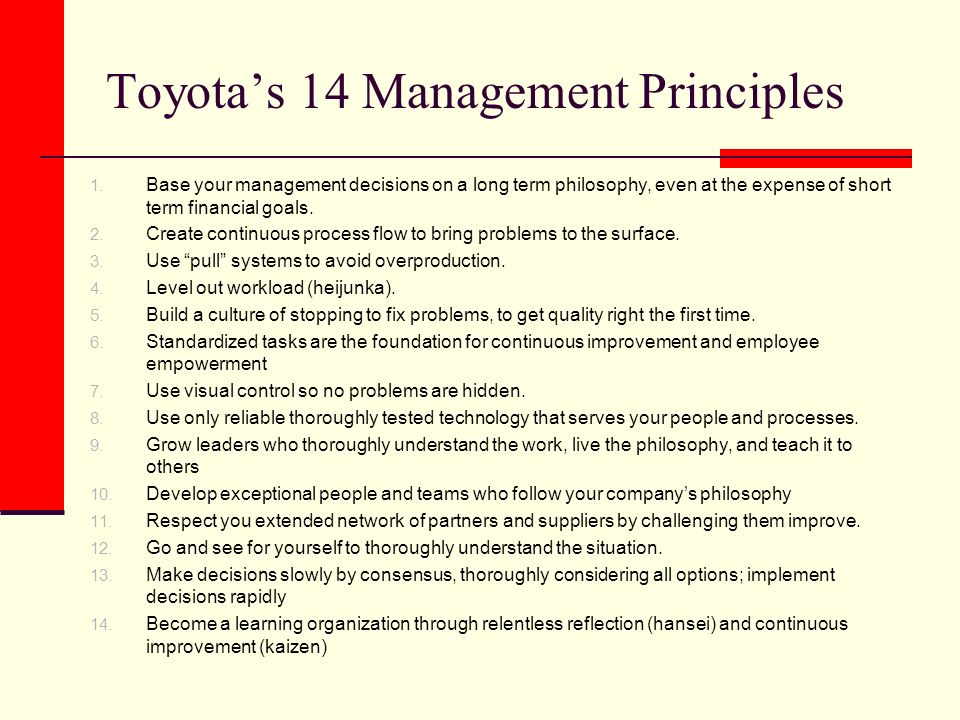

Toyota The Five Principles Of 5s Vrogue Co The toyota way training 2024 welcome to the toyota way and 5s training program – a comprehensive initiative designed to introduce participants to the world renowned methodologies of the toyota production system and 5s methodology. this training offers a unique opportunity for individuals to delve into the principles of kaizen (continuous improvement), 5s (sort, set in … toyota 5s program. The toyota way is based on two categories with five principles: continuous improvement (challenge, kaizen, genchi genbutsu) and respect for people (respect, teamwork, humility). it provides toyota's philosophy, values, and manufacturing approach. the first principle of challenge is often overlooked but is about working through obstacles to. History of 5s. 5s lean was developed by hiroyuki hirano in post war japan, where it was famously utilized by toyota. by integrating 5s principles into their already famous manufacturing framework dubbed the toyota production system or tps, toyota gained international prominence as a prolific producer of high quality motor vehicles. The book covers toyota’s history, successes, and ideas with many great toyota case studies. this post will focus on summarizing toyota’s 14 principles. how many of these principles are followed by your lean organization? principle 1: base your management decisions on a long term philosophy, even at the expense of short term financial goals.

Toyota The Five Principles Of 5s Vrogue Co History of 5s. 5s lean was developed by hiroyuki hirano in post war japan, where it was famously utilized by toyota. by integrating 5s principles into their already famous manufacturing framework dubbed the toyota production system or tps, toyota gained international prominence as a prolific producer of high quality motor vehicles. The book covers toyota’s history, successes, and ideas with many great toyota case studies. this post will focus on summarizing toyota’s 14 principles. how many of these principles are followed by your lean organization? principle 1: base your management decisions on a long term philosophy, even at the expense of short term financial goals.

The Five Principles Of The Toyota Way Vrogue Co

Comments are closed.