The Top 5 Takeaways From Our Cnc Machining Design Guide

The Top 5 Takeaways From Our Cnc Machining Design Guide Youtube There's a lot to keep track of when designing a part for cnc machining. this short video introduces you to xometry's comprehensive cnc design guide and cover. To combat this, make use of the following cnc design tips. incorporate a center drill at the end and use a center to keep the part spinning in a straight manner. keep the length to diameter ratio at or below 8:1 to minimize the risk of instability during machining.

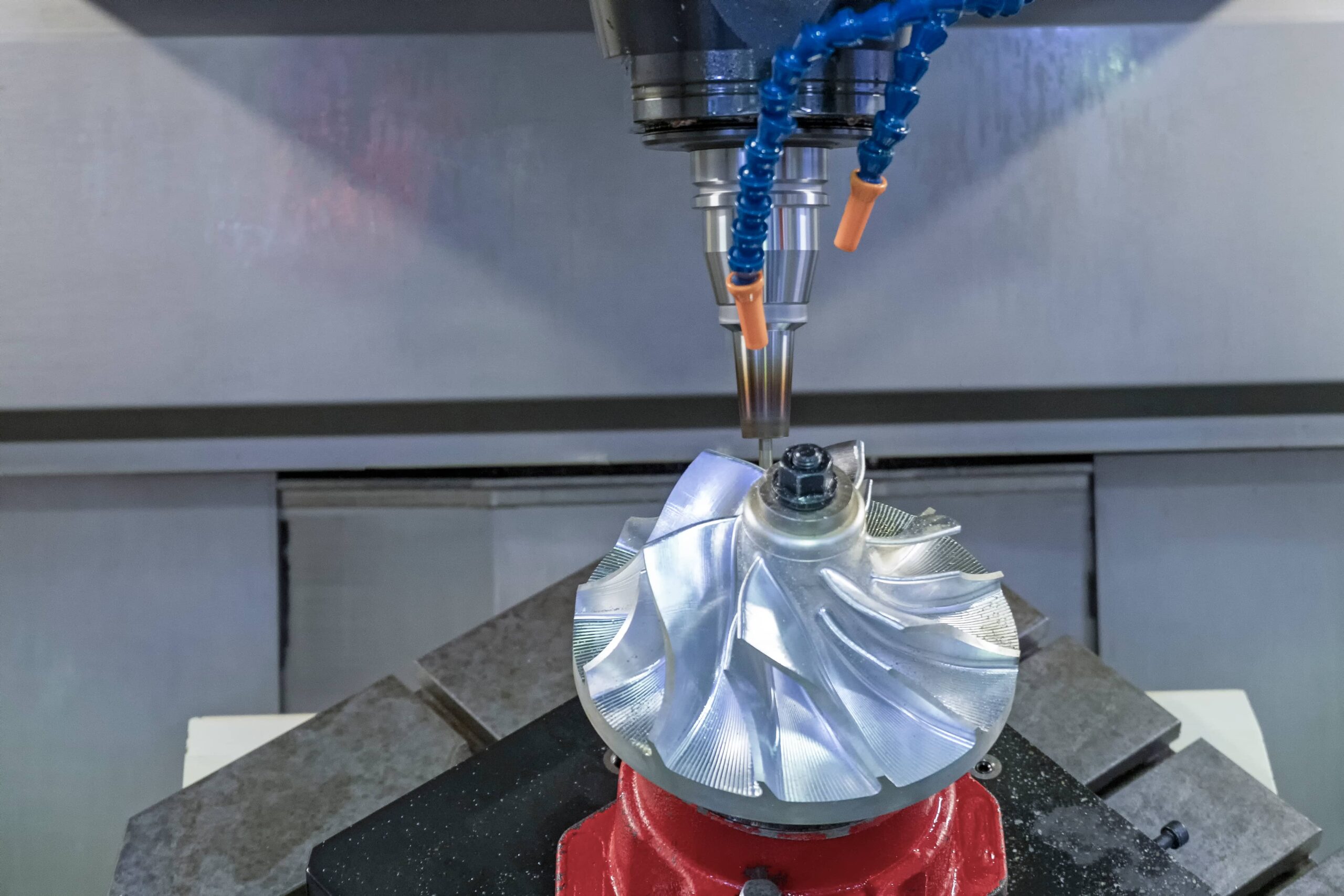

Cnc Machining Design Guide Best Prototypes Manufacturing Hk Co Limited Step 1: export your design to a cnc compatible cad file format. the file formats predominantly used in cnc machining are step and iges. these formats are open source, standardized and can be used across platforms. for best results: export your designs directly from your native cad software into the step file format. In this downloadable guide, we’ve compiled eight common dfm considerations that should remain top of mind when designing parts for cnc machining. you can save significant time and cost by checking your design against this list before submitting it for manufacturing. top 8 design for manufacturing considerations for cnc machining 1. 1. designing the cad model. the first step in cnc machining is creating a detailed cad (computer aided design) model of the part to be manufactured. this digital model serves as the blueprint for the entire machining process. software used: cad software like autocad, solidworks, or fusion 360. details: the model includes all dimensions. From a dfm for cnc machining perspective, you should consider how much stock material is required to make the part only when production volumes get very high (10,000 parts). generally stock material is recycled efficiently in cnc machining so optimizing material usage is not a big driver of dfm cost reduction in cnc machining. part setup.

The Ultimate Cnc Design Guide Checklist Fast Radius 1. designing the cad model. the first step in cnc machining is creating a detailed cad (computer aided design) model of the part to be manufactured. this digital model serves as the blueprint for the entire machining process. software used: cad software like autocad, solidworks, or fusion 360. details: the model includes all dimensions. From a dfm for cnc machining perspective, you should consider how much stock material is required to make the part only when production volumes get very high (10,000 parts). generally stock material is recycled efficiently in cnc machining so optimizing material usage is not a big driver of dfm cost reduction in cnc machining. part setup. Get started with a dfm expert. designing for manufacturability accelerates the cnc machining process, reduces operating costs, elevates energy eficiency, and helps product teams create clean, functional parts. refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like fast. Design guide: cnc machining. with all of today’s innovative cnc machining capabilities, it’s important to understand the strengths and trade offs of this process. download our guide for cnc manufacturability recommendations to optimize your designs, reduce machining time, and lower your costs.

Design Guide For Cnc Machining Xometry Europe Get started with a dfm expert. designing for manufacturability accelerates the cnc machining process, reduces operating costs, elevates energy eficiency, and helps product teams create clean, functional parts. refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like fast. Design guide: cnc machining. with all of today’s innovative cnc machining capabilities, it’s important to understand the strengths and trade offs of this process. download our guide for cnc manufacturability recommendations to optimize your designs, reduce machining time, and lower your costs.

The Ultimate Cnc Design Guide Checklist Fast Radius

Comments are closed.