Steam Boiler Process Flow Diagram

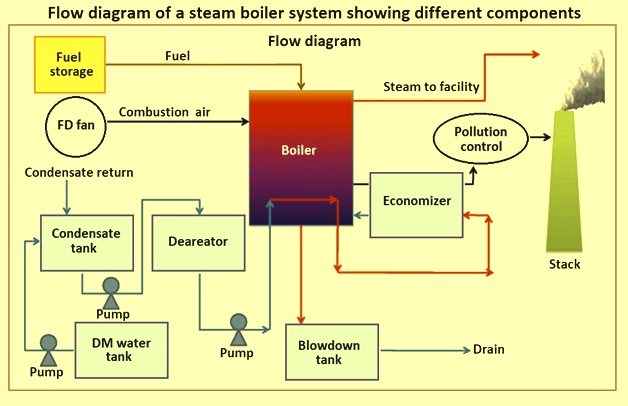

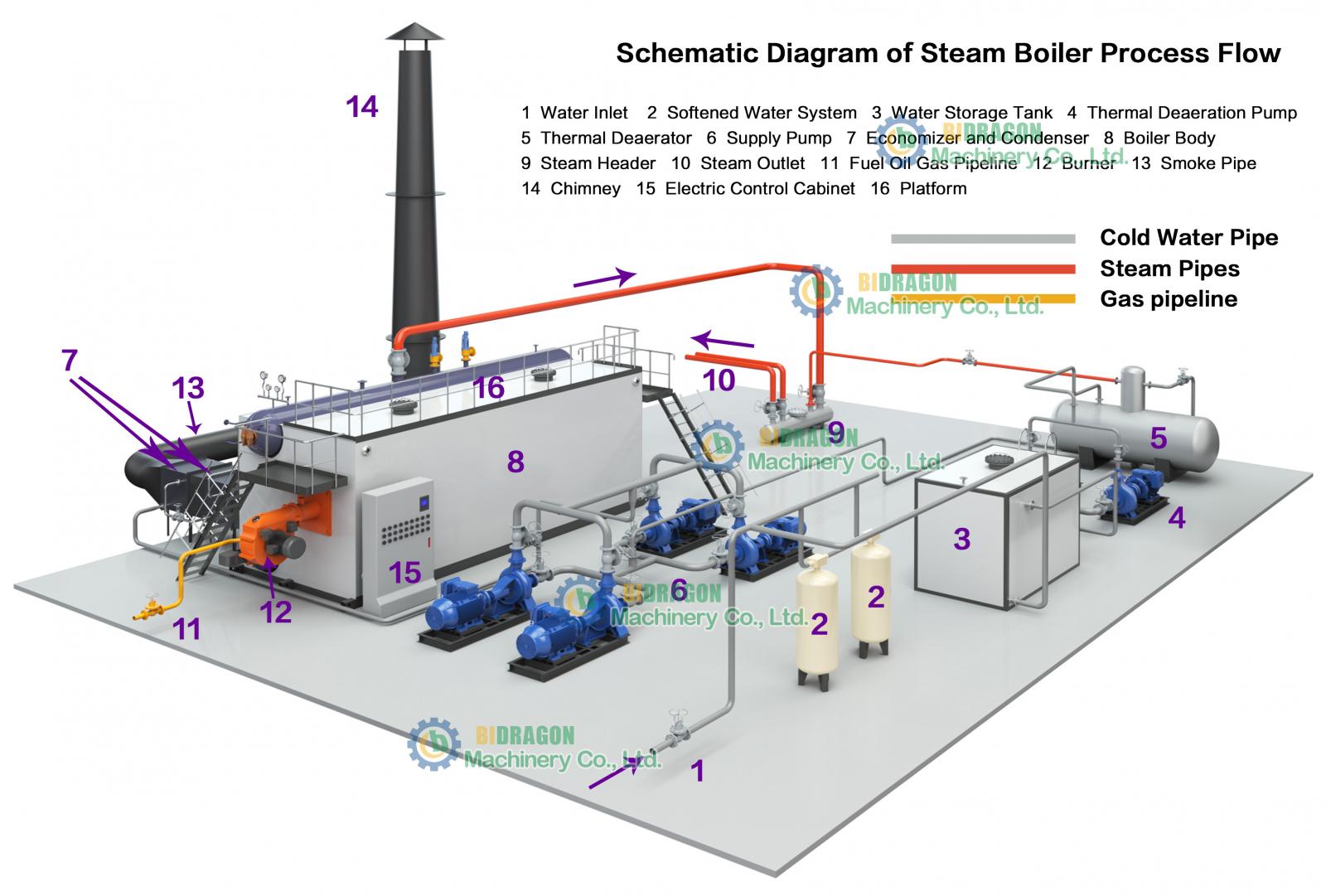

Flow Diagram Of A Steam Boiler Showing Different Components вђ Ispatguru Draw boiler process flow diagram easily with edrawmax: bit.ly 2ycdig3explore more process flow diagrams and free use and edit 5000 diagram examples. Figure 1. typical steam system figure 2. schematic diagram of a generic steam generating facility boilers controls stacks economizers fuel trains heat exchangers feedwater systems separators blowdown systems water treatment pumps piping steam traps pumps commercial and indus trial heating, process, and combination applications stack gases make.

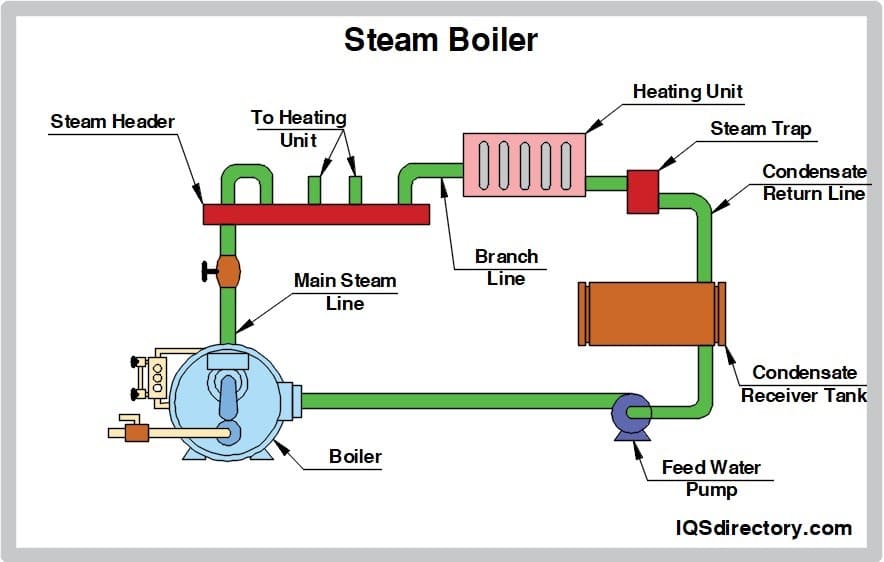

Steam Boiler What Is It How Does It Work Types Of A given mass of steam can hold five to six times more energy than an equivalent mass of water. it can be generated efficiently; many boilers operate with >80% thermal efficiency. it can be distributed easily by creating a pressure difference in the steam system. it is non toxic and does not damage the environment. Suspension. wet saturated steam is steam at the saturation temperature corresponding to pressure, and it contains water particles in suspension. • the quality of steam is expressed in terms of percent. for instance, if a quantity of wet steam consists of 90 percent steam and 10 percent moisture, the quality of the mixture is 90 percent. Fig 5 flow diagram of a steam boiler system showing different components. feedwater system – in this system, the water, which is supplied to the boiler and which is converted into steam, is called feedwater. the two sources of feedwater are condensate or condensed steam returned from the process and makeup water (treated raw water) which. A boiler is a closed vessel in which liquid (water) is heated and converted into gas form (steam). boiler is a closed vessel in which water or other liquid is heated, steam or vapour is generated, steam is super heated, or any combination thereof, under pressure or vacuum, for use external to itself, by the direct application of energy from the combustion of fuels, from electricity or nuclear.

Steam Boiler Process Flow Diagram Fig 5 flow diagram of a steam boiler system showing different components. feedwater system – in this system, the water, which is supplied to the boiler and which is converted into steam, is called feedwater. the two sources of feedwater are condensate or condensed steam returned from the process and makeup water (treated raw water) which. A boiler is a closed vessel in which liquid (water) is heated and converted into gas form (steam). boiler is a closed vessel in which water or other liquid is heated, steam or vapour is generated, steam is super heated, or any combination thereof, under pressure or vacuum, for use external to itself, by the direct application of energy from the combustion of fuels, from electricity or nuclear. Total continuous and intermittent blowdowns shall not be more than allowable figure specified in the boiler data sheet of steam generated, vendor to specify capacity at 100% rating. steam for fan drivers specified on the data sheet. exhaust steam from fan drivers specified on the data sheet. stack temperature, vendor to specify. Topping turbines receive high pressure steam from new boilers, with the exhaust steam of the new turbine set at the same pressure as the old boilers. this steam supplies the existing turbines. in a radial flow turbine, steam flows outward from the shaft to the casing. these turbines are utilized for special applications and are common in europe.

Steam Boiler Process Flow Diagram Total continuous and intermittent blowdowns shall not be more than allowable figure specified in the boiler data sheet of steam generated, vendor to specify capacity at 100% rating. steam for fan drivers specified on the data sheet. exhaust steam from fan drivers specified on the data sheet. stack temperature, vendor to specify. Topping turbines receive high pressure steam from new boilers, with the exhaust steam of the new turbine set at the same pressure as the old boilers. this steam supplies the existing turbines. in a radial flow turbine, steam flows outward from the shaft to the casing. these turbines are utilized for special applications and are common in europe.

Steam Boiler Process Flow Diagram

Comments are closed.