Soldering Smd Resistor And Push Button

Soldering Smd Resistor And Push Button Youtube #resistor #button #pcb #pcbuild #electronic #circuit heatgun =yihua 862bd flux = mechanic or super flux paste temperature =350 degrees celsius air pressure =. In this video tutorial, we will show you some easy tips for soldering smd push buttons. soldering smd push buttons can be a challenging task, but with the ri.

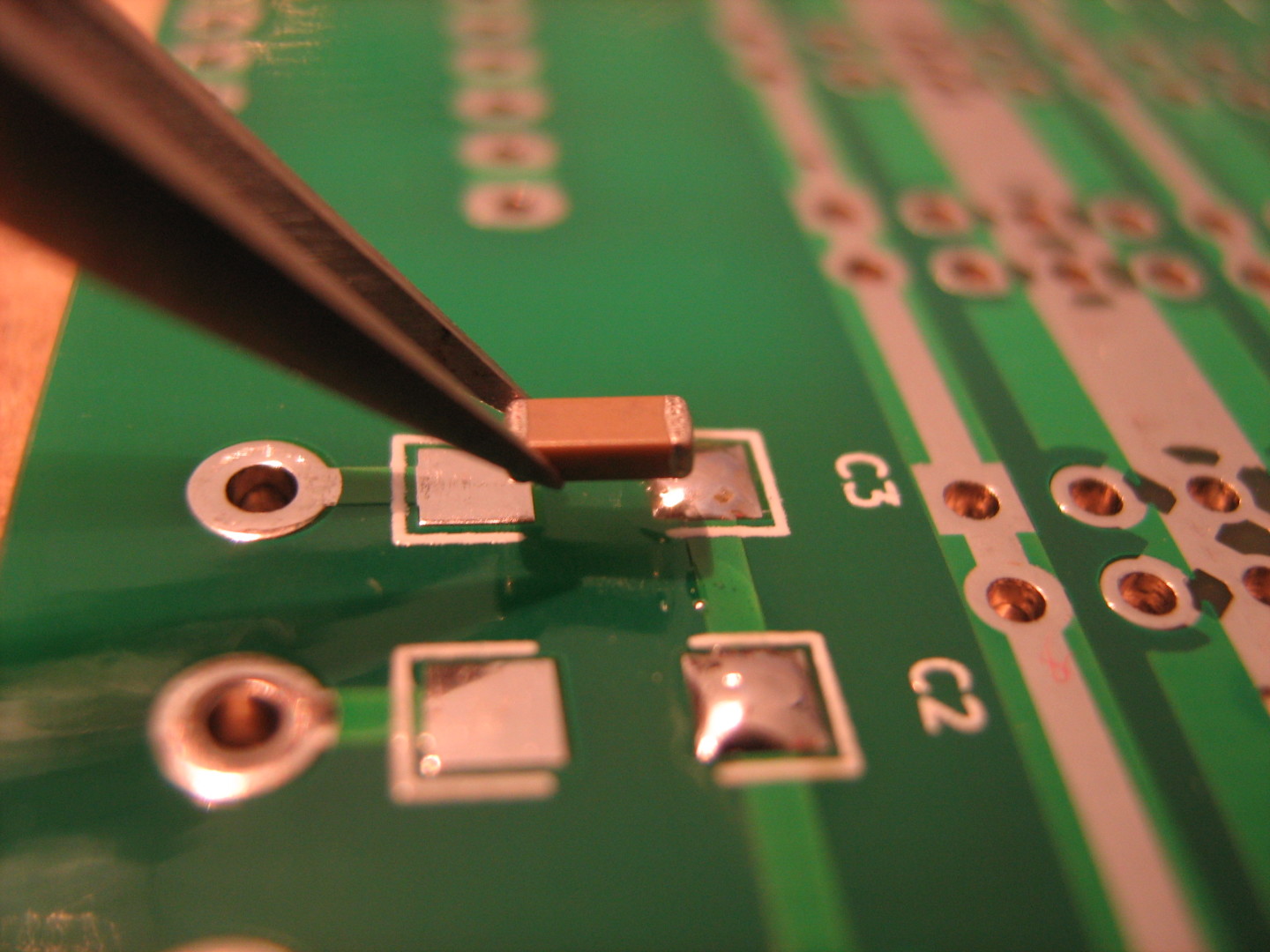

Smd Soldering Surface Mount Soldering Guide How To Solder Smd How to solder smd components is nicely shown in my latest soldering tutorial .beginners and more advanced solderers can learn a few new tricks from the world. Step 2: apply solder paste to pcb. for a small pcb with few components, you can just spread solder paste on the pads manually, but for complex pcbs, a stencil, as shown in the picture, is needed. once you have the board firmly held on the table (as shown), place the stencil over it, and apply a little bit of solder paste. Step 4: soldering resistor, capacitor, etc. place pcb on a flat surface, then secure it in place using tape. now using soldering iron apply solder on one pad, the push the component in its place the re heat the solder and solder one terminal. now solder the remaining terminal. Place and align the chip using tweezers. hold the chip in place while touching the corner pad with the tip of the soldering iron so that the solder melts the pin and the pad together. check the alignment of the chip. if it is not in its place, use your soldering iron to loosen the pin chip and align the chip properly.

How To Hand Solder Smd Electronic Thingsвђ And Stuff Step 4: soldering resistor, capacitor, etc. place pcb on a flat surface, then secure it in place using tape. now using soldering iron apply solder on one pad, the push the component in its place the re heat the solder and solder one terminal. now solder the remaining terminal. Place and align the chip using tweezers. hold the chip in place while touching the corner pad with the tip of the soldering iron so that the solder melts the pin and the pad together. check the alignment of the chip. if it is not in its place, use your soldering iron to loosen the pin chip and align the chip properly. Re: desoldering soldering plastic membrane push buttons. « reply #1 on: january 04, 2021, 11:08:30 am ». for well known switch brands it's usually a non issue. just hot air them as you would any component. for your cheaper china aliexpress brand buttons you do have to be careful. keep the temp under control to prevent the plastic case melting. We connect the push button on the left to 5v which will, when under pressure, be switched to digital pin 7. the push button on the right is connected to pin 6, but we add a 10k resistor as shown in the picture below. what we expect is that dasduino’s pins 7 and 6 will have low (0) readings when not activated, or high (1) when buttons are pushed.

Soldering 1206 Smd Resistor Youtube Re: desoldering soldering plastic membrane push buttons. « reply #1 on: january 04, 2021, 11:08:30 am ». for well known switch brands it's usually a non issue. just hot air them as you would any component. for your cheaper china aliexpress brand buttons you do have to be careful. keep the temp under control to prevent the plastic case melting. We connect the push button on the left to 5v which will, when under pressure, be switched to digital pin 7. the push button on the right is connected to pin 6, but we add a 10k resistor as shown in the picture below. what we expect is that dasduino’s pins 7 and 6 will have low (0) readings when not activated, or high (1) when buttons are pushed.

Comments are closed.