Smart Manufacturing How Iot And Data Analytics Are Tr Vrogue Co

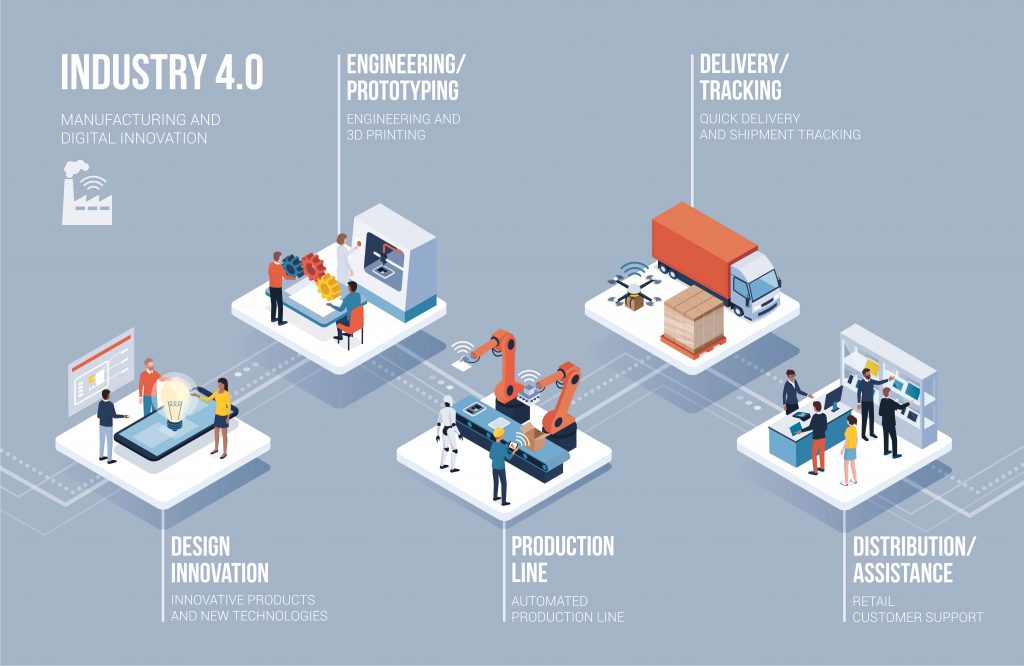

Smart Manufacturing And Iot Benefits And Trends Sam S Vrogue Co Iot in manufacturing is an increasing trend where companies can take advantage of faster networks, smarter devices and improvements in edge technology. combined, these technologies pave the way for the capabilities of industry 4.0. continue reading to learn about the applications and benefits of iot in manufacturing and smart factories. The modern manufacturing industry is investing in new technologies such as the internet of things (iot), big data analytics, cloud computing and cybersecurity to cope with system complexity, increase information visibility, improve production performance, and gain competitive advantages in the global market.

The Role Of Iot In Smart Manufacturing Sam Solutions Vrogue Co In short, smart manufacturing is the strategy, and the smart factory is where it comes to life. is industry 4.0 the same as smart manufacturing? industry 4.0 is the current wave of automation and data exchange in manufacturing, featuring things like iot and cloud computing. however, smart manufacturing is just a piece of the industry 4.0 puzzle. A global mckinsey survey suggested that the growth of smart manufacturing business software solutions may be attributed to the increasing emphasis on real time data analysis and predictive maintenance to boost the adoption of iot and smart manufacturing. also, read – how the convergence of iot is driving industry 4.0. this blog highlights:. What is smart manufacturing: definition. smart manufacturing (sm) revolutionizes production by employing machinery connected to the internet to monitor and enhance manufacturing. at its core, sm aims to boost operational efficiency and productivity by identifying opportunities for automation and harnessing real time data insights. This pa per present s a review of iot techn ologies and systems tha t are enabl ers of data . driven innova tions in smart manufacturing. the inte rnet has evolved from hard wire d compute r.

Smart Manufacturing How Iot And Data Analytics Are Tr Vrogue Co What is smart manufacturing: definition. smart manufacturing (sm) revolutionizes production by employing machinery connected to the internet to monitor and enhance manufacturing. at its core, sm aims to boost operational efficiency and productivity by identifying opportunities for automation and harnessing real time data insights. This pa per present s a review of iot techn ologies and systems tha t are enabl ers of data . driven innova tions in smart manufacturing. the inte rnet has evolved from hard wire d compute r. Rittal uses our edge appliance to manage 250 networked production machines that generate up to 18 terabytes of data each day. after combining real time iot data from factory stations with product information from the sap erp system, oncite analyzes the data in near real time. as a result, managers can quickly visualize the status of production. Inventory management. most manufacturing companies use legacy software such as erp and supply chain management to try and optimize their supply chain processes. inventory management is a critical part of the link between production and supply chain management that iiot facilitates. real time transactional data can extend in both directions.

The Role Of Iot Platforms In An Evolving Business And Vrogue Co Rittal uses our edge appliance to manage 250 networked production machines that generate up to 18 terabytes of data each day. after combining real time iot data from factory stations with product information from the sap erp system, oncite analyzes the data in near real time. as a result, managers can quickly visualize the status of production. Inventory management. most manufacturing companies use legacy software such as erp and supply chain management to try and optimize their supply chain processes. inventory management is a critical part of the link between production and supply chain management that iiot facilitates. real time transactional data can extend in both directions.

Comments are closed.