Smart Lean Combining Industry 4 0 With Opex

Smart Lean Combining Industry 4 0 With Opex Youtube The complete program to combine the smart factory with the lean factory to drive improvements to costs, quality and throughput. we will cover a variety of to. Existing research on opex methodology implementation in the context of process digitalization and automation is commonly referred to as the integration of lean, six sigma or lean six sigma and industry 4.0 (pongboonchai empl et al., 2023; tissir et al., 2023; skalli et al., 2022): essentially past research explored (1) the integration.

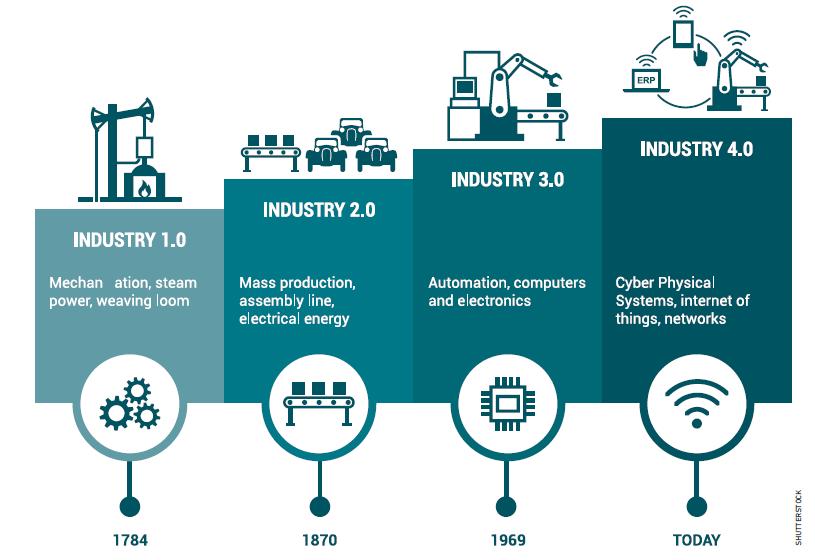

Operational Excellence 4 0 The research has investigated the internal factors acting as a roadblock to lean and industry 4.0 adoption. further studies may consider external factors to lean and industry 4.0 implementation. also, further research may consider other operational excellence approaches and extend further to relevant sectors. Indeed, in most cases, the integrated application of lean management and industry 4.0—which we call lean industry 4.0—is the most effective way to reach the next level of operational excellence. manufacturers that have successfully deployed lean industry 4.0 can reduce conversion costs by as much as 40% in five to ten years—considerably. Furthermore, the ranked performance metrics can assist managers and practitioners in evaluating the manufacturing system and, as a result, strategic planning for improvement.,according to the authors, this is a novel approach for integrating opex strategies with advanced industry 4.0 technologies, and no comparable study has been found in the. Opex and industry 4.0 practices are not yet fully integrated into the companies’ strategic plans and managing operations are not a priority: 49% of companies do not consider opex in the strategic plan. when considering industry 4.0 practices, this number drops to 33% and 45% of them do not involve their workers in training on the opex.

Combiner L Industrie 4 0 Et Le Lean Management Abdul Latif Jameelв Furthermore, the ranked performance metrics can assist managers and practitioners in evaluating the manufacturing system and, as a result, strategic planning for improvement.,according to the authors, this is a novel approach for integrating opex strategies with advanced industry 4.0 technologies, and no comparable study has been found in the. Opex and industry 4.0 practices are not yet fully integrated into the companies’ strategic plans and managing operations are not a priority: 49% of companies do not consider opex in the strategic plan. when considering industry 4.0 practices, this number drops to 33% and 45% of them do not involve their workers in training on the opex. The findings suggest total productive maintenance as one exemplary constituting element representing the ‘what’ level and change management as a discipline with answers concerning the ‘how’ level. the paper offers a holistic view for practitioners facing the need for an integrated implementation of industry 4.0 and lean management. By applying opex 2.0, the implementation of digital twins in combination with automated process mining supports human action and decision making. traditional lean principles are therefore brought to the next level: a real time digital twin mines process data, identifying process deviations as they occur.

Comments are closed.