Safety Operating Cranes And Hoists Tip 8

Safety Operating Cranes And Hoists Tip 8 Gradual lifting. when working with cranes and hoists, it is important to proceed gradually. it is important to limit yourself to one movement at a time so that you keep an overview. as far as overview is concerned, you absolutely must not lose sight of the load while moving lifting. especially also for the safety of your colleagues. Overhead crane safety tips card: before operating the crane and applying the load. addresses issues associated with overhead crane safety, including tips for overhead crane operators to follow before operating cranes and applying loads. overhead crane safety tips card: operating the crane and moving the load. addresses issues associated with.

Safety Operating Cranes And Hoists Tip 8 A complete understanding of force, weight distributions, and rigging techniques will ensure a safe, stable lift of even the most irregular and heavy loads. 8. understand load radius. in order to safely operate a crane, it’s vital to understand how a crane works and what forces are working against it. Cranes and hoists are indispensable in construction and industrial settings, facilitating the lifting and movement of heavy loads. however, their operation poses significant safety risks, making comprehensive operator training and proper load handling procedures imperative. this article highlights the key aspects of crane and hoist safety. Operating a crane is a high stakes job that requires precision and adherence to safety protocols. the crane school's comprehensive guide explores the challenges faced by crane operators and provides practical tips on how to avoid common mistakes that can lead to significant dangers on the job. from insufficient training to neglecting daily inspections, this guide emphasizes the importance of. Review the crane and hoist safety program on a periodic basis and revise as necessary. provide technical assistance regarding the regulatory requirements of cranes, hoists, chains, and slings. provide or arrange training for the safe operation of overhead cranes, and the inspection procedures for cranes, hoists, chains, and slings.

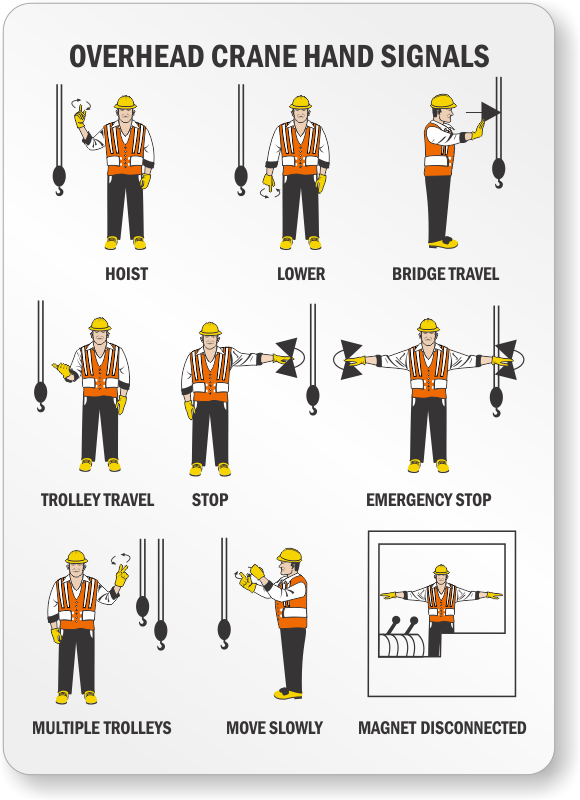

Crane Safety Signs Hoist Safety Signs Mysafetysign Operating a crane is a high stakes job that requires precision and adherence to safety protocols. the crane school's comprehensive guide explores the challenges faced by crane operators and provides practical tips on how to avoid common mistakes that can lead to significant dangers on the job. from insufficient training to neglecting daily inspections, this guide emphasizes the importance of. Review the crane and hoist safety program on a periodic basis and revise as necessary. provide technical assistance regarding the regulatory requirements of cranes, hoists, chains, and slings. provide or arrange training for the safe operation of overhead cranes, and the inspection procedures for cranes, hoists, chains, and slings. The occupational and health safety administration (osha) defines a crane as a large family of construction machinery. osha defines cranes as construction machinery that’s used to hoist, lower, and move a suspended load. there is a lot of engineering that goes into the design and construction of a crane to ensure that it can move and lift. Not level: operating a crane on an uneven surface can lead to instability and potential tipping. always ensure that the crane is level before beginning any lifting operation. wind: high winds can significantly impact the stability and safe operation of cranes, especially when lifting large or flat objects.

Comments are closed.