Rolled Throughput Yield Is A Key Measure Of Improvement

Rolled Throughput Yield Rty Definition Rolled throughput yield is a key measure of business performance. it also measures quality and it's impact on business performance. The rolled throughput rate is a factor of the first pass yield rates of each step being multiplied together. with this case, 10 steps all with 95% first pass yields rates will be about 60%, which is not as high as you would like. this shows how even 5% of products, when accumulated over many steps, can add up to be a large quantity of rework.

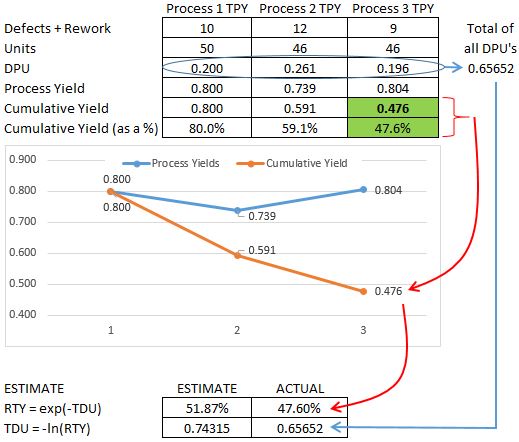

Rolled Throughput Yield Rty Ny Fy Tpy The rolled throughput yield (rty) is calculated by multiplying the first pass yield (fpy) or success rate of each step in a process. the formula for rty is: rty = fpy1 * fpy2 * fpy3 * …. * fpyn. where: rty is the rolled throughput yield. fpy1, fpy2, fpy3, …. fpyn are the first pass yields for each step in the process. Rolled throughput yield (rty) is a metric that quantifies a process or product’s overall quality by multiplying the defects per million opportunities (dpmo) of each process step. unlike fty, which only focuses on the defects in the first step, roll throughput yield considers all defects and rework this provides insight into the overall. Rolled throughput yield (rty) is a measure of the overall effectiveness of a process that accounts for the probability of passing through multiple stages without defects. it combines the yields from each step in a process to provide a single metric that reflects the likelihood of a product or service meeting quality standards at the end of the. Benefits of calculating rolled throughput yield. calculating rolled throughput yield (rty) offers several benefits, particularly in process improvement and quality management. some of the key advantages include: comprehensive view of process quality: rty considers the cumulative effect of defects across multiple stages or steps in a process. it.

Comments are closed.