Push Vs Pull System Examples At Karin Wright Blog

Push System Vs Pull System In Manufacturing Management The pull system is a lean manufacturing method that uses the just in time strategy of not producing goods until an order is received. instead of forecasting demand, the pull system produces ‘as needed’. this is particularly useful for companies that deal with high demand uncertainty, low product mix, and low importance of economies of scale. A push system relies on market demand and forecasting to dictate production levels. a pull system, however, uses current customer demand to dictate what to produce and when. push systems are standard in industries that produce a wider variety of products and longer lead times. pull systems are usually seen in industries with shorter lead times.

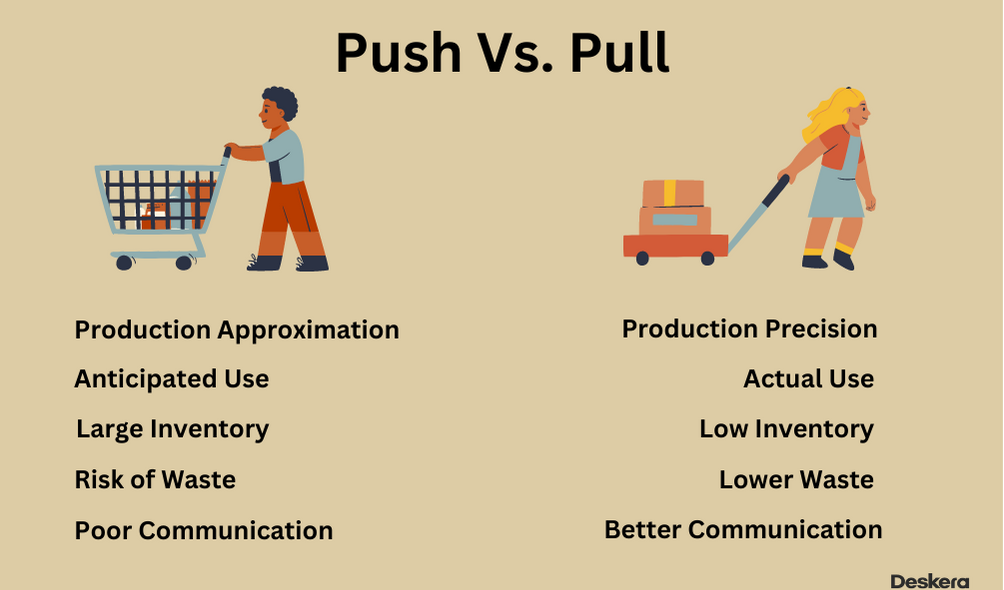

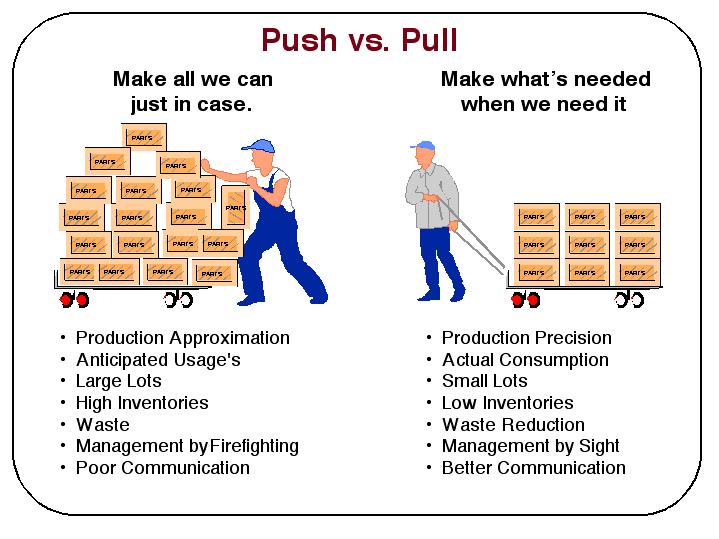

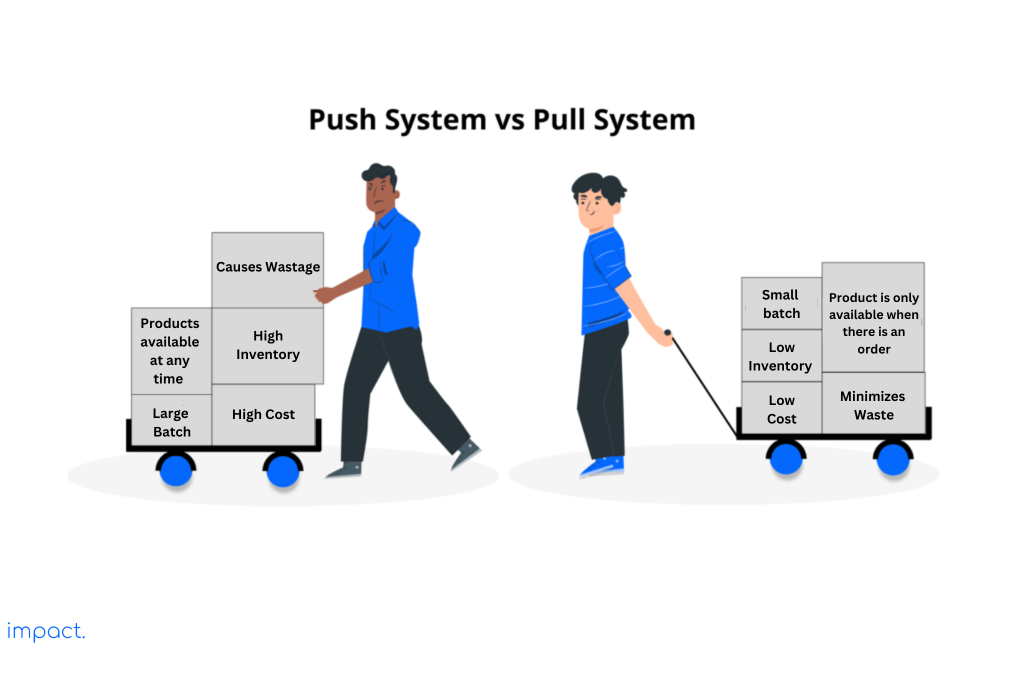

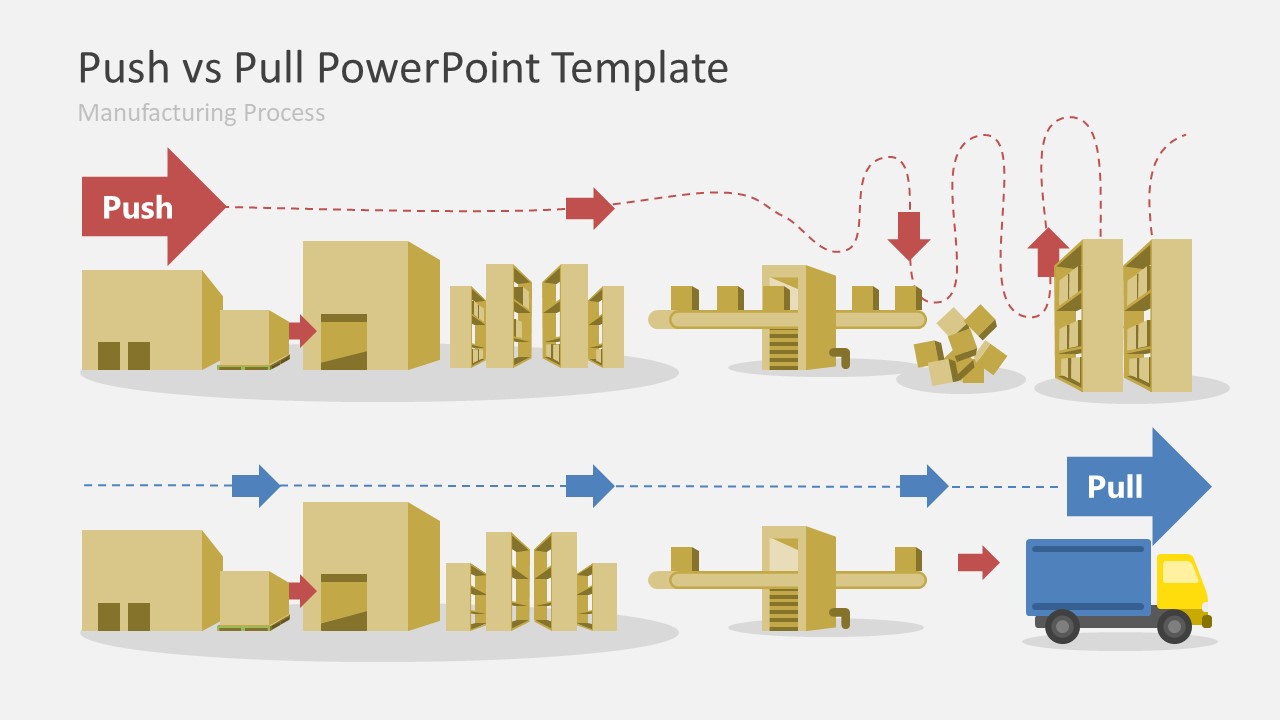

Push Vs Pull The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. it dictates when and how much to produce. what else sets push and pull systems apart is the amount of wip inventory. Understanding the push system. a push system is an approach to inventory management where production and distribution are typically driven by demand forecasts, meaning that a business will stock inventory based on predicted customer demand. this system is often best suited for items with predictable demand patterns, stable market conditions, or. In push manufacturing, orders are released as determined by the erp system in order to meet shipment completion dates. in pull, a customer order starts the sequence of processing steps. the inventory buffers present in a push environment increase tolerance to unplanned downtime. in contrast, in a pull system, machine breakdowns are extremely. A vital aspect of this strategy involves choosing the right production system, namely the push, pull, or hybrid approaches. the push system focuses on forecasting demand and manufacturing accordingly, while the pull system responds directly to consumer demand, producing only what is immediately required.

Push Vs Pull System Examples At Karin Wright Blog In push manufacturing, orders are released as determined by the erp system in order to meet shipment completion dates. in pull, a customer order starts the sequence of processing steps. the inventory buffers present in a push environment increase tolerance to unplanned downtime. in contrast, in a pull system, machine breakdowns are extremely. A vital aspect of this strategy involves choosing the right production system, namely the push, pull, or hybrid approaches. the push system focuses on forecasting demand and manufacturing accordingly, while the pull system responds directly to consumer demand, producing only what is immediately required. There is a time and place for push manufacturing, especially when you manufacture complex, high variety products and tend to have a lot of work in progress (wip). push production environments tend to be characterized by long lead times and or make to stock (mts) situations. processing large batches of items at a maximum rate, based on. Pull methods force processes to improve so they increase flexibility and reduce inventory. changes to customer demand can be made more quickly. customer relationships are typically stronger and “stickier.”. push is based on “just in case” thinking. pull is based on “just in time.”.

Push Vs Pull System Examples At Karin Wright Blog There is a time and place for push manufacturing, especially when you manufacture complex, high variety products and tend to have a lot of work in progress (wip). push production environments tend to be characterized by long lead times and or make to stock (mts) situations. processing large batches of items at a maximum rate, based on. Pull methods force processes to improve so they increase flexibility and reduce inventory. changes to customer demand can be made more quickly. customer relationships are typically stronger and “stickier.”. push is based on “just in case” thinking. pull is based on “just in time.”.

Comments are closed.