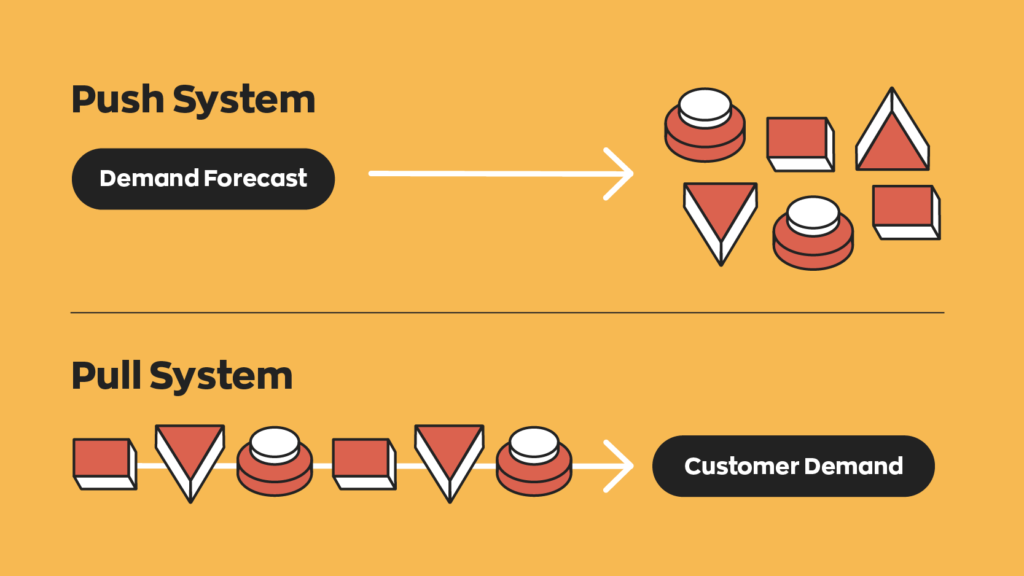

Push And Pull System Infographic

Push And Pull System In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s efficiency, inventory levels, and overall responsiveness to customer demand. the choice between push system vs pull system is not just a matter of preference but a strategic decision that can make or break your. A push system relies on market demand and forecasting to dictate production levels. a pull system, however, uses current customer demand to dictate what to produce and when. push systems are standard in industries that produce a wider variety of products and longer lead times. pull systems are usually seen in industries with shorter lead times.

Push Vs Pull System Manufacturing An In Depth Analysis The pull system is a lean manufacturing method that uses the just in time strategy of not producing goods until an order is received. instead of forecasting demand, the pull system produces ‘as needed’. this is particularly useful for companies that deal with high demand uncertainty, low product mix, and low importance of economies of scale. The principles of lean aim to streamline production, reduce waste, and ultimately deliver value to the customer. among these principles, the concepts of “push,” “pull,” and “flow” are foundational. these strategies dictate how products and information move through a manufacturing system, influencing everything from inventory. Understanding the push system. a push system is an approach to inventory management where production and distribution are typically driven by demand forecasts, meaning that a business will stock inventory based on predicted customer demand. this system is often best suited for items with predictable demand patterns, stable market conditions, or. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. it dictates when and how much to produce. what else sets push and pull systems apart is the amount of wip inventory.

Comments are closed.