Production Training Auto Visual Inspection

Production Training Auto Visual Inspection Youtube The demand for high quality, high efficiency, and personalized manufacturing is rising in the industry 4.0 era, highlighting the importance of automation vision inspection. machine vision, part of artificial intelligence (ai), allows 100% control over production processes — and at top speeds. by using machine learning algorithms for image. The problem with existing visual inspection approaches. manufacturing processes typically include one or more steps where the product is visually inspected for defects. typically, visual inspection is a highly manual process that can be time consuming and prone to errors. over the years, rule based visual inspection machines have also emerged.

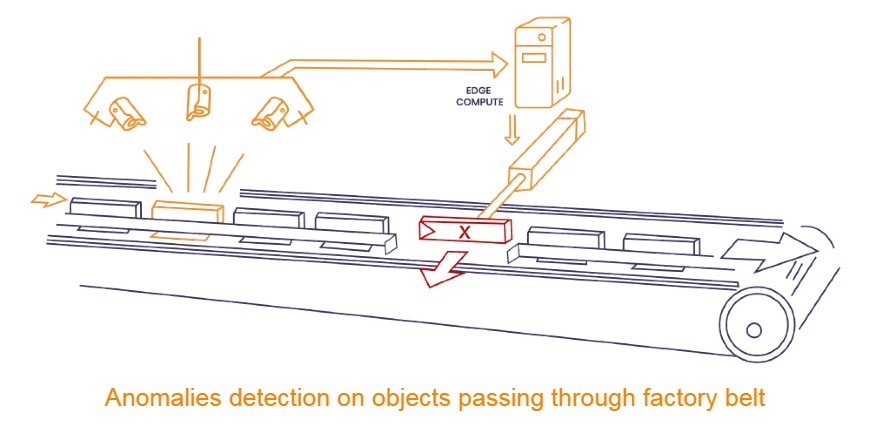

Tutorial Automated Visual Inspection Using Transfer L Vrogue Co Vision systems can be integrated directly into production lines to guide the manufacturing process. for example, some systems, like keyence’s xt, are exceptionally accurate, down to 10 µm which allows them to detect cracks and surface imperfections otherwise invisible to the naked eye. this particular system can also guide welding robots and. Automated visual inspection refers to the use of specialized cameras, sensors, and supporting computer systems and algorithms to examine products or components for defects or deviations from desired specifications. this process, often part of a larger quality control system, relies on visual data to make assessments, substituting human visual. April 11, 2024. automated visual inspection uses сomputer vision to analyze images or videos of products and detect defects, anomalies, or quality issues without human intervention. implemented into assembly lines and production floors, avi enhances quality control and efficiency in manufacturing processes. conventionally, manufacturers employ. Visual inspection is a form of non destructive testing (ndt). nondestructive methods allow inspectors to assess a system or component without permanently changing it. in addition to visual inspections, ndt also includes inspection techniques such as emissions, radiographic, x ray and infrared, and ultrasonic testing.

Automated Visual Inspection Avi For Manufacturing April 11, 2024. automated visual inspection uses сomputer vision to analyze images or videos of products and detect defects, anomalies, or quality issues without human intervention. implemented into assembly lines and production floors, avi enhances quality control and efficiency in manufacturing processes. conventionally, manufacturers employ. Visual inspection is a form of non destructive testing (ndt). nondestructive methods allow inspectors to assess a system or component without permanently changing it. in addition to visual inspections, ndt also includes inspection techniques such as emissions, radiographic, x ray and infrared, and ultrasonic testing. Ibm maximo visual inspection puts the power of computer vision ai capabilities into the hands of your quality control and inspection teams. it makes computer vision, deep learning, and automation more accessible to your technicians as it’s an intuitive toolset for labelling, training, and deploying artificial intelligence vision models. Visual inspection is the process of verifying, traditionally with the unaided eye, whether a product, component, or system is in a fit state to be shipped. in the case of a finished product, visual inspection ensures that the product can be used safely and effectively by a customer. in the case of component manufacturing, it can help identify.

Advanced Automated Visual Inspection Systems For Industrial Ibm maximo visual inspection puts the power of computer vision ai capabilities into the hands of your quality control and inspection teams. it makes computer vision, deep learning, and automation more accessible to your technicians as it’s an intuitive toolset for labelling, training, and deploying artificial intelligence vision models. Visual inspection is the process of verifying, traditionally with the unaided eye, whether a product, component, or system is in a fit state to be shipped. in the case of a finished product, visual inspection ensures that the product can be used safely and effectively by a customer. in the case of component manufacturing, it can help identify.

Apa Itu Automated Visual Inspection

Comments are closed.