Process Of Kaizen Kaizen Change Management Process Improvement

Process Of Kaizen Kaizen Change Management Process Improvement Riset The kaizen change management model champions these agile methods over dramatic overhauls. kaizen’s incremental change initiatives might involve trials to explore fresh concepts and process modifications and can motivate team members to propose enhancements within their workspaces. this method offers a more sustainable and staff friendly. Kaizen example. a kaizen blitz, or kaizen event, is a short term improvement project designed to accomplish significant results in process management and quality issues. . kaizen events focus on improving a specific area of the company, meaning they are ideal to deploy in a business process or department of 50 or fewer empl.

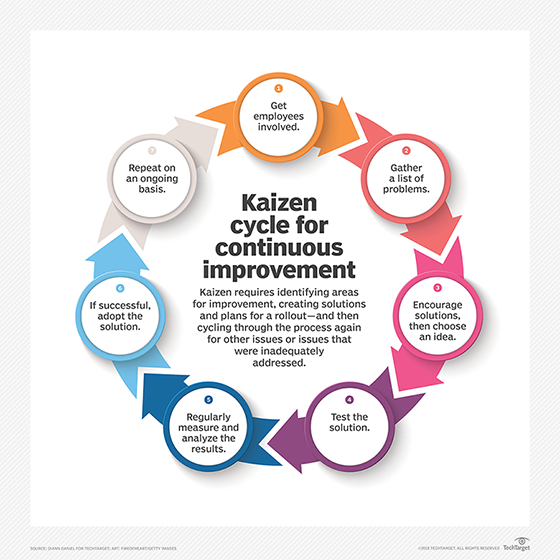

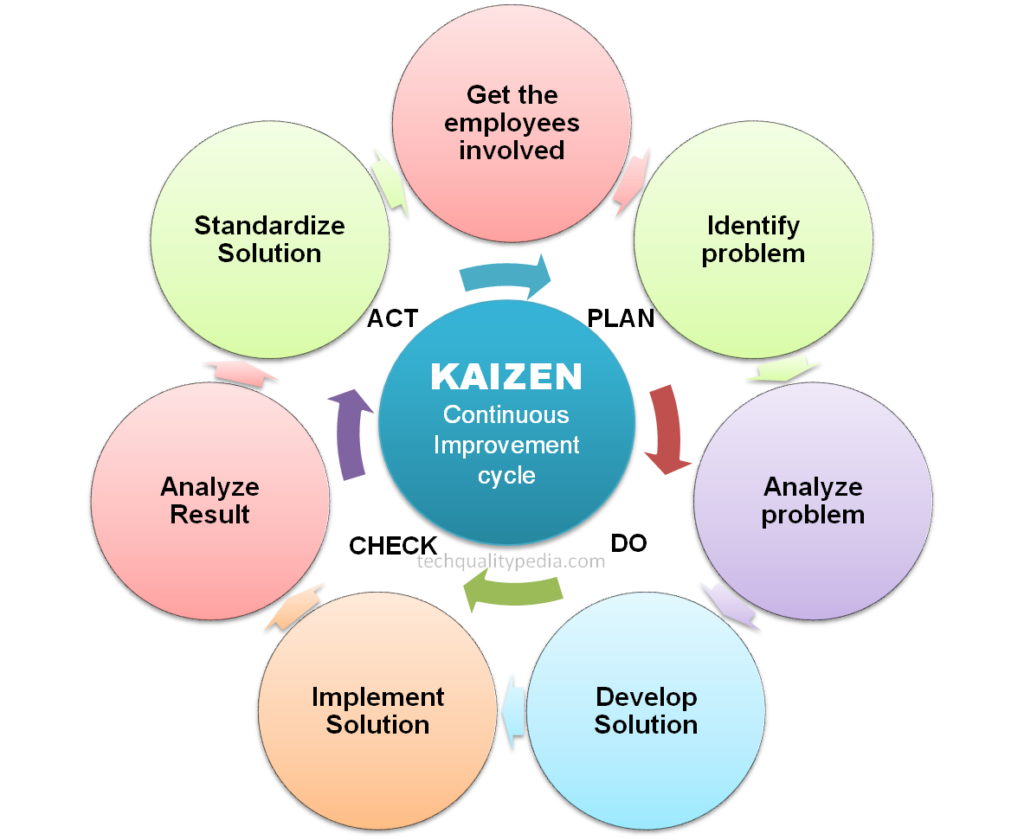

What Is Kaizen Continuous Improvement The kaizen process. the continuous cycle of kaizen activity has six phases: 1. identify a problem or opportunity 2. analyze the process 3. develop an optimal solution 4. implement the solution 5. study the results and adjust 6. standardize the solution. figure 1.continuous improvement cycle. Kaizen is a japanese term that means “improvement” or “change for the better.”. kaizen is a business term that refers to a continuous improvement process that focuses on making small, incremental changes to processes and operations to improve efficiency, quality, and productivity. the kaizen approach emphasises employee participation in. This process is designed to empower people and engage team members in the work process. according to the information on toyal’s website, the company uses the kaizen principle to underpin the aim of forever thinking about the next, learning from the past, and improving the toyota production system. 2. nestle. The importance of change management in kaizen. change management is important for the successful implementation of kaizen. it’s the process of planning, implementing, and evaluating organizational changes. it involves communicating, engaging, and supporting stakeholders, especially employees who may be resistant to change.

Kaizen Process Flow Chart This process is designed to empower people and engage team members in the work process. according to the information on toyal’s website, the company uses the kaizen principle to underpin the aim of forever thinking about the next, learning from the past, and improving the toyota production system. 2. nestle. The importance of change management in kaizen. change management is important for the successful implementation of kaizen. it’s the process of planning, implementing, and evaluating organizational changes. it involves communicating, engaging, and supporting stakeholders, especially employees who may be resistant to change. The kaizen process is based on the pdca (plan do check act) cycles. this means that an organization first identifies areas for improvement, develops a plan to make changes, implements the changes, and then checks the results to see if further improvements can be made. this continuous cycle of improvement leads to a culture of innovation and. Kaizen is a strategy where employees at all levels of a company work together proactively to achieve regular, incremental improvements to the manufacturing process. in a sense, it combines the collective talents within a company to create a powerful engine for improvement. kaizen is also referred to as continuous improvement.

Comments are closed.