Pressure In Cooling System Diesel Engine

Pressure In Cooling System Diesel Engine 10 posts · joined 2014. #1 · may 1, 2014. my friend has a 2005 6.0l diesel that we have done head gaskets and stud kits on. also have eliminated the egr cooler. lately, there is excessive pressure in the cooling system. this has been analyzed by an independent shop and determined to not be combustion gases in the cooling system. There are a few things that can cause excessive pressure in cooling system: a radiator cap that is not sealing properly. a leak in the cooling system. a failed water pump. a thermostat that is stuck closed. if you notice that your car’s engine is overheating, you should check these things to see if they are the cause.

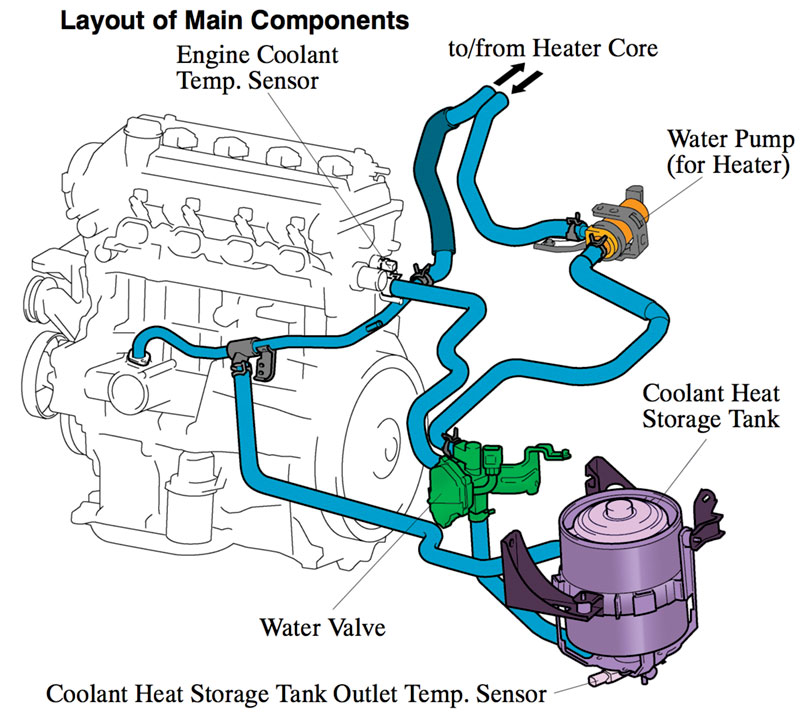

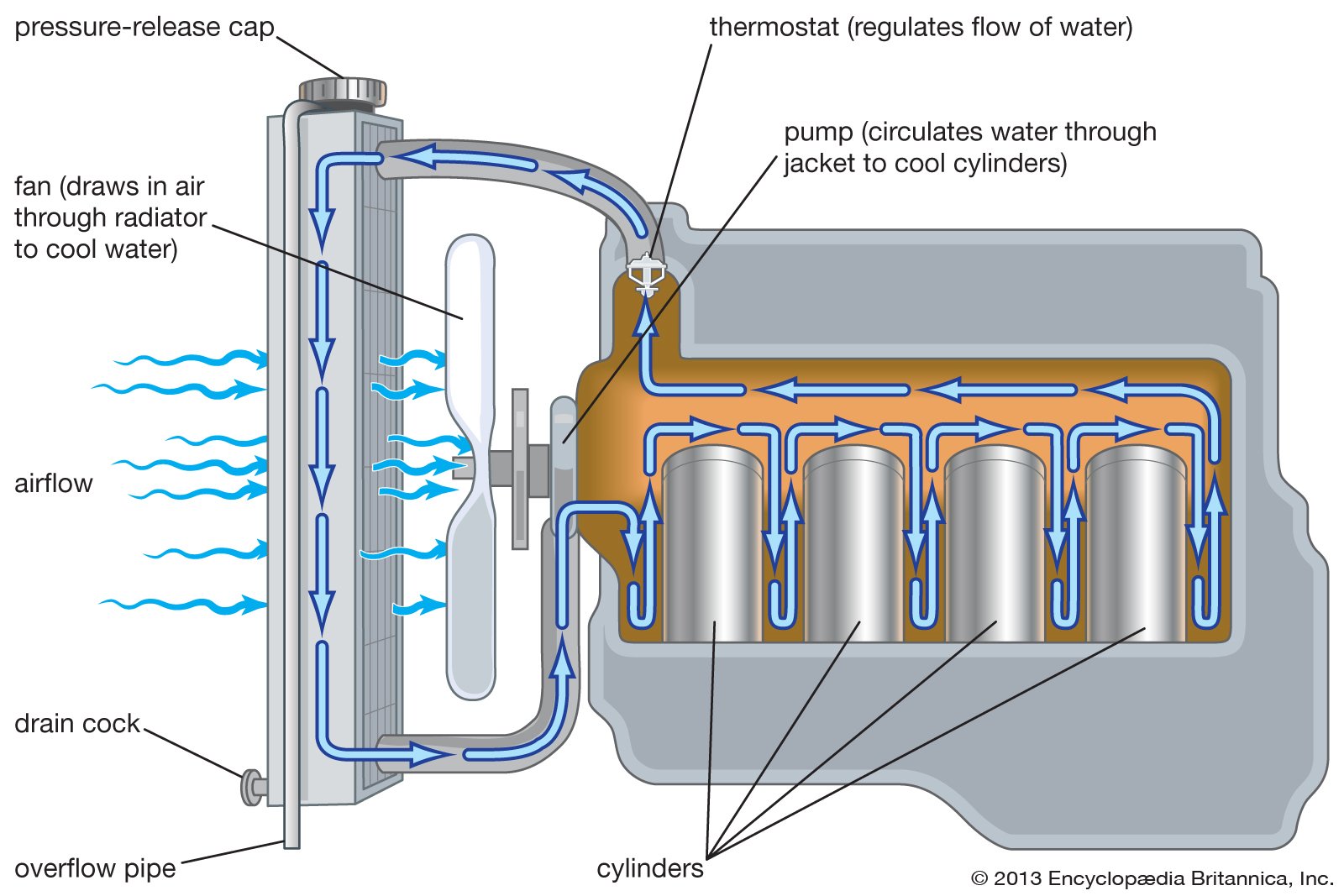

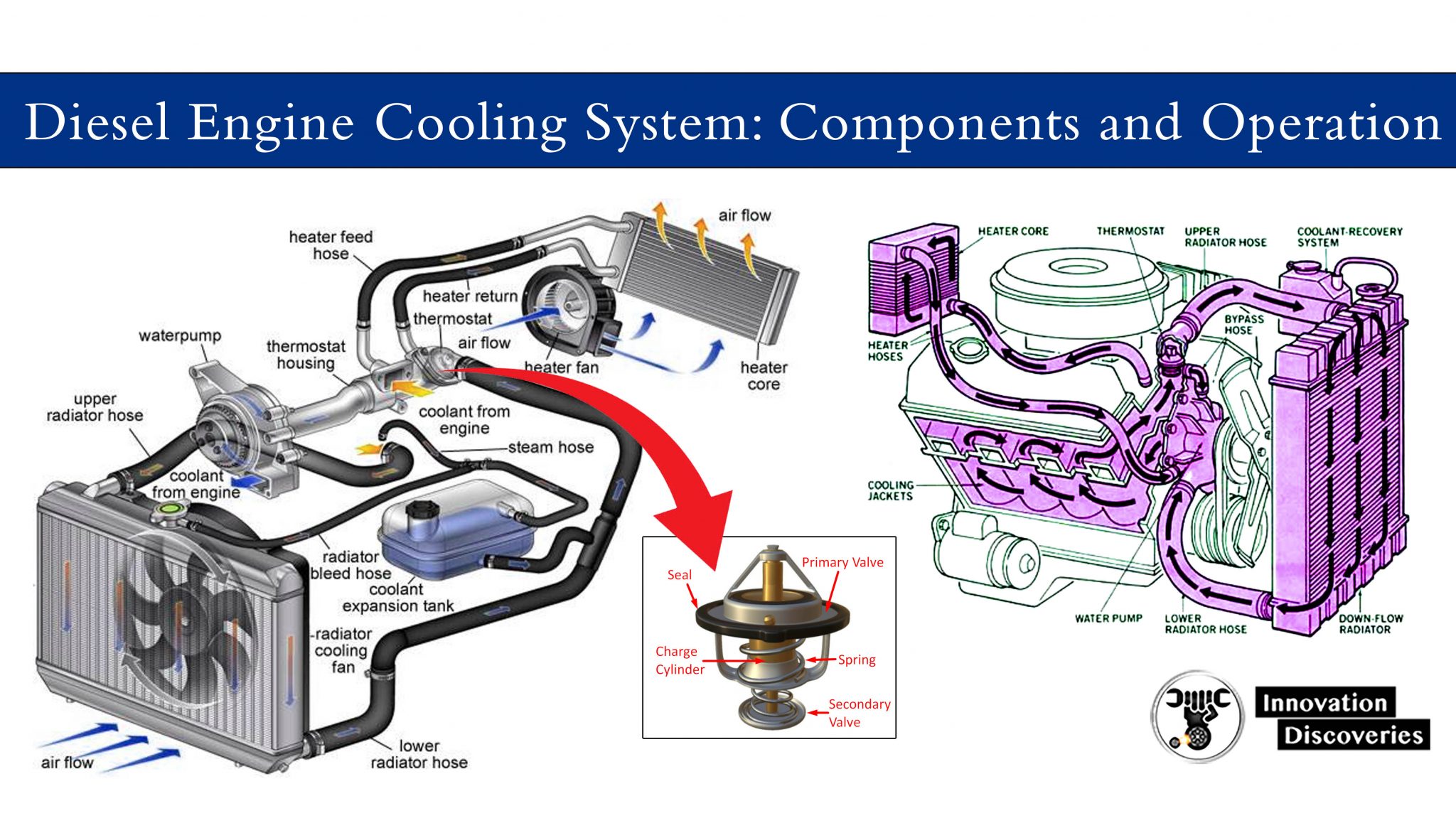

Diesel Engine Cooling System Components And Operation The purpose of the coolant (antifreeze or water) flowing through your diesel is to regulate the heat within the cylinder head and engine block that's created by the combustion process. in order to. The operating pressure of the cooling system and the lubricating system can result in the mixing of the fluids if there is a leak between the systems: cylinder head gasket, lubricating oil cooler, etc. transmission power steering hydraulic fluid can also leak into the coolant through radiator fluid coolers, if equipped. refer to the oem service manual. Including pressure testing with the oil filter off to see if the oil cooler was contributing to any of the oily film. current working theory is that the oily film is from the water pump failure. there was no evidence of coolant in the oil. transmission fluid levels are good and have not changed. the upper rad hose is not pressurized while. The electrical system in diesel engines comprises various components, including batteries, alternators, and glow plugs. common issues include faulty glow plugs, battery degradation, and corroded wiring. these symptoms often indicate problems with the battery, charging system, or electrical connections. signs of electrical system issues include.

Air Cooled Diesel Engine Operating Temperature At Daniel Claar Blog Including pressure testing with the oil filter off to see if the oil cooler was contributing to any of the oily film. current working theory is that the oily film is from the water pump failure. there was no evidence of coolant in the oil. transmission fluid levels are good and have not changed. the upper rad hose is not pressurized while. The electrical system in diesel engines comprises various components, including batteries, alternators, and glow plugs. common issues include faulty glow plugs, battery degradation, and corroded wiring. these symptoms often indicate problems with the battery, charging system, or electrical connections. signs of electrical system issues include. Coolant recommendations for the series 60 engine are listed in table "series 60 engine air system, fuel system, and cooling system parameters" .. a pressurized cooling system permits higher temperature operation than a non pressurized system. it is essential that the cooling system is kept clean and leak free, that the filler cap and. Use the proper coolant. system maintenance. keep your coolant system clean. remove dirt and debris from the radiator core area. ensure proper airflow through the fins. use compressed air to remove dust and light dirt. if dealing with an oil film, use a cleaning solution and water at low pressure.

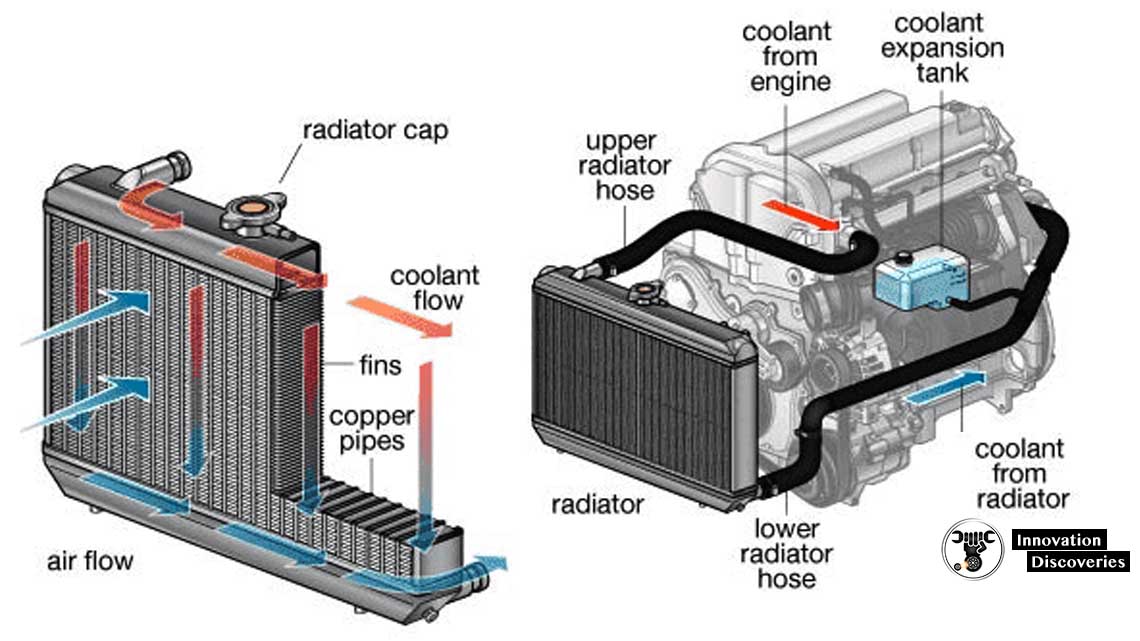

How An Engine Cooling System Works How A Car Works Coolant recommendations for the series 60 engine are listed in table "series 60 engine air system, fuel system, and cooling system parameters" .. a pressurized cooling system permits higher temperature operation than a non pressurized system. it is essential that the cooling system is kept clean and leak free, that the filler cap and. Use the proper coolant. system maintenance. keep your coolant system clean. remove dirt and debris from the radiator core area. ensure proper airflow through the fins. use compressed air to remove dust and light dirt. if dealing with an oil film, use a cleaning solution and water at low pressure.

Diesel Engine Cooling System Components And Operation

Comments are closed.