Power Tool Safety Tips Power Tool Safety Safety Post

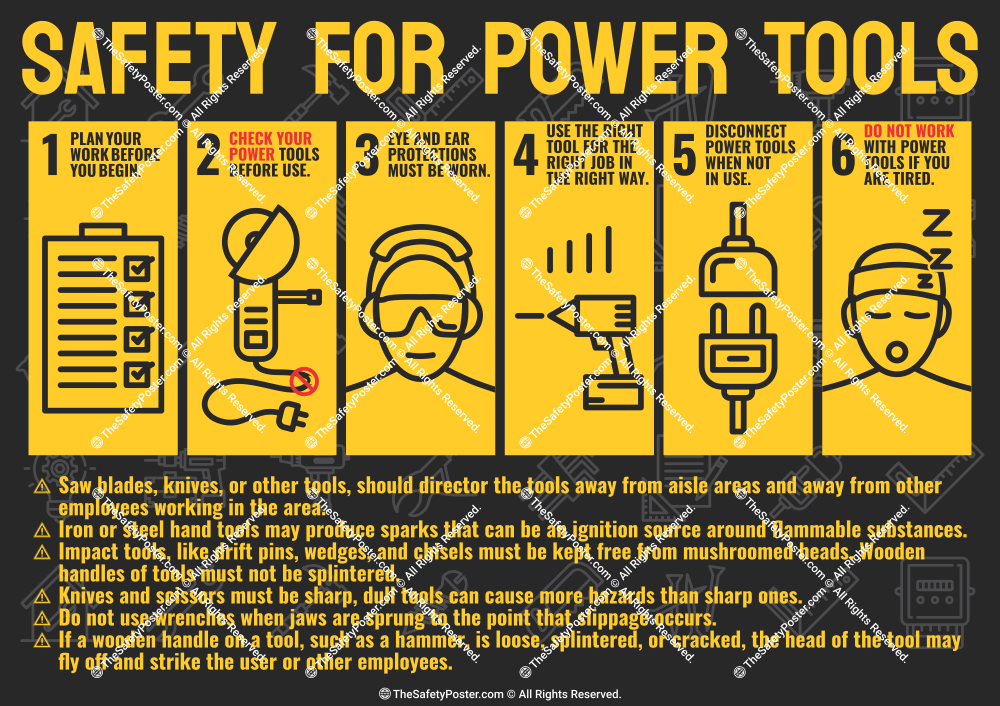

Safety For Power Tools Safety For Tools Poster Tool Safety Never store an air gun that is loaded. use a safety clip or retainer to prevent attachments from being ejected during operation, and use a chip guard when using high pressure compressed air for cleaning. be sure to limit the nozzle pressure to 30 pounds per square inch. always wear eye protection. When maintaining and inspecting power tools, keep the followings tips in mind: use properly sized fittings and parts for the power tools. keep tool cutting edges sharp and clean. remove the adjustment keys and tools before operating the power tool. check that power cords are intact (no nicks, frays, or kinks) to prevent shock and fire hazards.

Electrical Safety Posters Power Tool Safety Tips вђ Safety Poste Here are some comprehensive power tool safety tips to keep in mind: 1. wear protective gear: always wear appropriate protective gear, including safety glasses, gloves, and earplugs when using power tools. this will protect you from flying debris, loud noises, and potential hand injuries. 2. Select the right filter for the type of dust. wear hearing protection like ear plugs or muffs to prevent gradual hearing damage from noise. gloves provide protection from cuts, scrapes, and vibration. avoid gloves around rotating parts. remove jewelry, tie back long hair, and avoid loose clothing around power tools. Cleaning: keeping tools clean and free of dust, debris, and buildup ensures proper operation and reduces the risk of malfunctions. inspections: employees should be encouraged to perform pre use inspections of their power tools to identify any potential hazards, such as damaged cords, loose parts, or dull blades. In conclusion, hand and power tool safety relies on a combination of proper usage and regular inspection practices. ensuring that workers are trained to select, handle, and maintain tools correctly is paramount in preventing accidents. incorporating pre use inspection routines, regular maintenance schedules, and employee training on inspection.

Comments are closed.