Piston Cooling System Diagram

Oil Piston Cooling There are two basic methods of oil piston cooling, both methods utilizing the existing main engine lube oil from the sump. in the first method the oil is supplied to channels cast into the piston crown through the centre of a hollow piston rod, by a swinging arm supply unit. the second method the oil is similarly supplied to the piston rod, but in this case a nozzle plate at the base of the. Man b&w piston: the new man engine uses simple bore cooling piston and jet nozzels, which comprises of oil passage within the piston crown for uniform cooling. the man engine also uses a top layer thermal coating over the crown, known as inconel 625 coat, which is 8mm thick and protects the crown surface from overheating.

Piston Cooling In 2 Stroke Marine Diesel Engine Marinerspoint Pro Spray jet cooling—the piston is cooled by a continuous oil spray jet from an oil nozzle directed at the bottom of the piston. cooling channels—the piston is cooled by oil flowing through a cooling channel or gallery incorporated into the piston. one or more oil spray nozzles feed oil into the cooling channel through inlet openings in the. How piston cooling is done| oil cooling of piston arrangement material of piston|if you want to read these video in article form then please visit marineless. Assume the weight of oil passing the piston in time t is w 0. then. q0 = w0 x 10 x 2. if the same same amount of heat is removed from the oil cooled piston as from the water cooled piston in the equivalent time t then, q0 = qw. and w0 x 10 x 2 = 1.0 x 14 x 4. so, w0 = (1.0 x 14 x 4) (10 x 2) = 56 20. Piston cooling using water was a popular means of cooling the piston crown. the crown has cooling channels cast into it that surround the internal edges and the top of the crown. these are the areas susceptible to excessive heat from the combustion of heavy fuel oil. the water is circulated around the piston crown through telescopic pipes, through a seawater cooler before entering the storage.

Piston Cooling Water Assume the weight of oil passing the piston in time t is w 0. then. q0 = w0 x 10 x 2. if the same same amount of heat is removed from the oil cooled piston as from the water cooled piston in the equivalent time t then, q0 = qw. and w0 x 10 x 2 = 1.0 x 14 x 4. so, w0 = (1.0 x 14 x 4) (10 x 2) = 56 20. Piston cooling using water was a popular means of cooling the piston crown. the crown has cooling channels cast into it that surround the internal edges and the top of the crown. these are the areas susceptible to excessive heat from the combustion of heavy fuel oil. the water is circulated around the piston crown through telescopic pipes, through a seawater cooler before entering the storage. A separate piston cooling system is used to limit any contamination from piston cooling glands to the piston cooling system only. sea water cooling system the various cooling liquids which circulate the engine are themselves cooled by sea water. the usual arrangement uses individual coolers for lubricating oil, jacket water, and the piston. A water cooling system for a slow speed diesel engine is shown in figure above. it is divided into two separate systems: one for cooling the cylinder jackets, cylinder heads and turbo blowers; the other for piston cooling. the cylinder jacket cooling water after leaving the engine passes to a sea water.

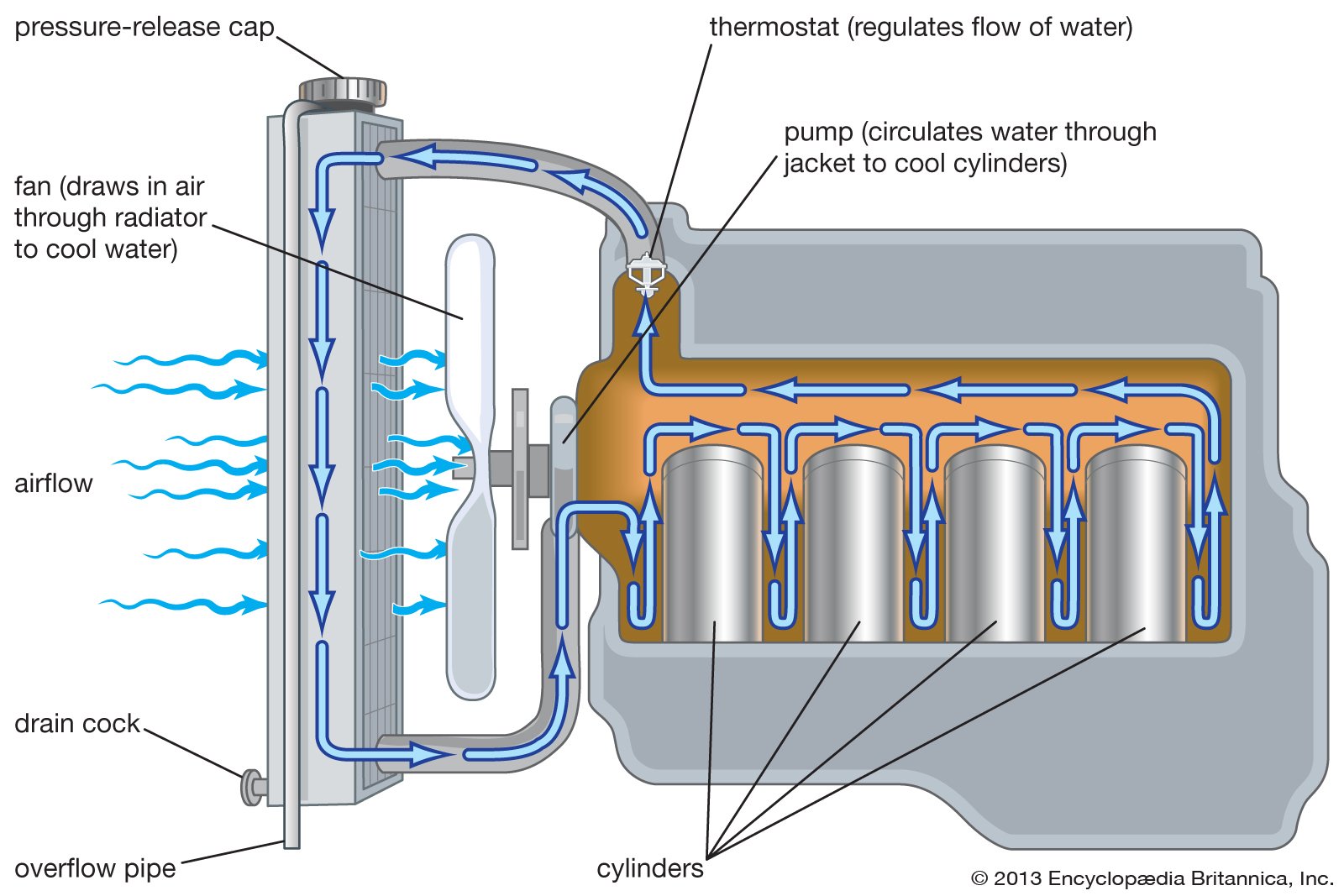

Diagram Of Cooling System For Engine At Tina Thrash Blog A separate piston cooling system is used to limit any contamination from piston cooling glands to the piston cooling system only. sea water cooling system the various cooling liquids which circulate the engine are themselves cooled by sea water. the usual arrangement uses individual coolers for lubricating oil, jacket water, and the piston. A water cooling system for a slow speed diesel engine is shown in figure above. it is divided into two separate systems: one for cooling the cylinder jackets, cylinder heads and turbo blowers; the other for piston cooling. the cylinder jacket cooling water after leaving the engine passes to a sea water.

Comments are closed.