Pdf Principles Of Lean Manufacturing Poster Principles Of Lean

Pdf Principles Of Lean Manufacturing Poster Principles Of Lean Poster principles of lean manufacture download the pdf file at: visit technologystudent for more information on manufacturing systems. chevron . Use—the management principles once known as “lean manufacturing.” this collection of articles and interviews constitutes the third in a series that began in 2008 with banking on lean. that compendium articulated how lean ideas could be adapted to challenging financial services environments where, for example, the work is.

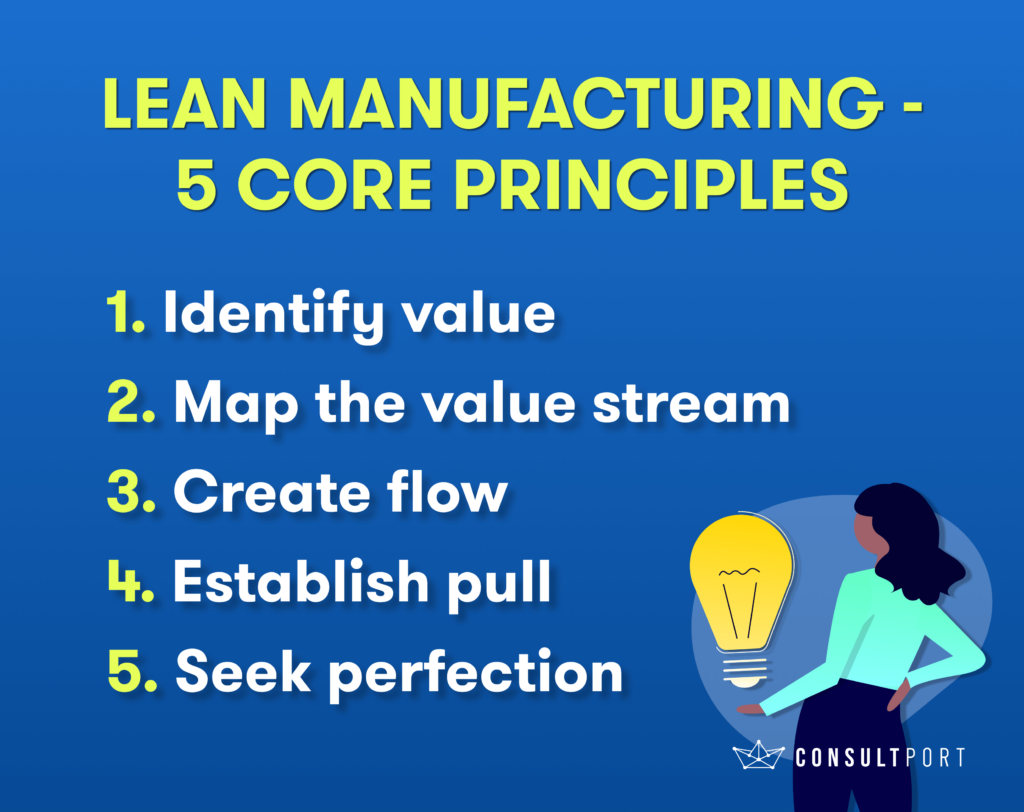

Lean Manufacturing 5s Principles Poster The five principles of lean manufacturing – value, value stream, flow, pull, and perfection – provide a powerful framework for improving efficiency, reducing waste, and delivering superior value to customers. while each principle is important in its own right, they are most effective when implemented together as an integrated system. Motivation and learning. figure 2 a lean leader pushing the principles towards the employee, may enable the. employee to understand the lean mindset directly. the reasoning behind using principles. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles. Lean manufacturing: principles, tools, and methods. 1 8bosch rexroth corporation. a properly designed lean workcell must be easy to reconfigure. in fact, the ability to change the process and go from good part to good part as quickly as possible is a must. the faster the changeover, the less production time is lost.

Lean Manufacturing 5 Core Principles Explained With Examples The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles. Lean manufacturing: principles, tools, and methods. 1 8bosch rexroth corporation. a properly designed lean workcell must be easy to reconfigure. in fact, the ability to change the process and go from good part to good part as quickly as possible is a must. the faster the changeover, the less production time is lost. Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Of bringing on a lean transformation.cellular manufacturing: arranging production work stations and equipment in a sequence that supports a smooth flow of materials and components through the production pr. cess with minimal transport or delay. shifting from traditional “batch and queue” mass production systems to a “single piece flow.

5 Principles Of Lean Manufacturing Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Of bringing on a lean transformation.cellular manufacturing: arranging production work stations and equipment in a sequence that supports a smooth flow of materials and components through the production pr. cess with minimal transport or delay. shifting from traditional “batch and queue” mass production systems to a “single piece flow.

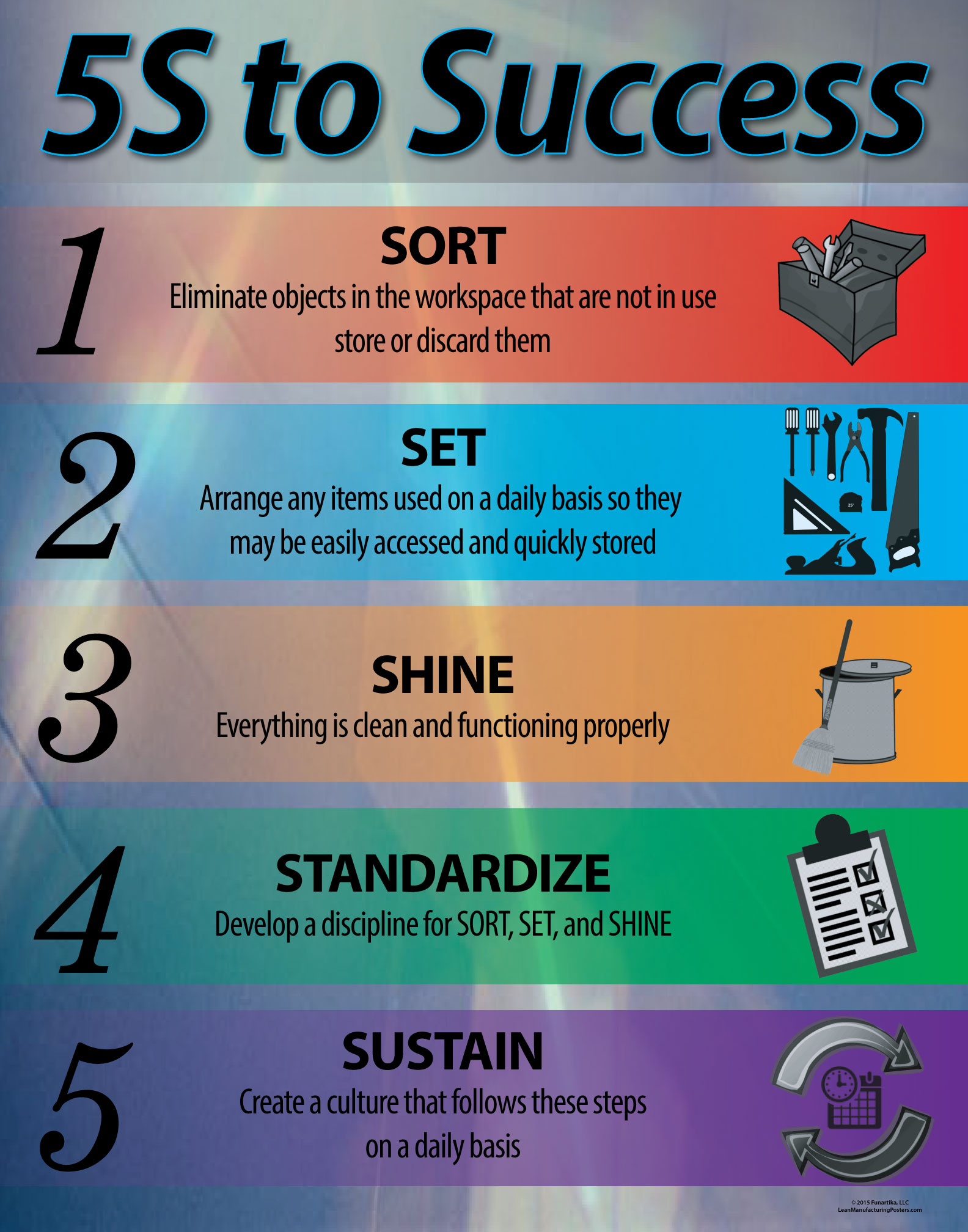

Lean Manufacturing Posters For Training Safety Health Quality And

Comments are closed.