Overall Equipment Effectiveness O E E Kaufman Global

Overall Equipment Effectiveness O E E Kaufman Global Calculation By kaufman global. overall equipment effectiveness (o.e.e) measures the time that an asset (machine) is producing product versus the theoretical maximum amount of time the equipment could be producing. developed by denso during the 1960s and into the 1980s as part of total productive maintenance (tpm), and later refined by the japan institute. The key measure for total productive maintenance is overall equipment effectiveness (oee). oee is the time that an asset (machine) is producing product versus the theoretical maximum amount of time the equipment could be producing. tpm is based on employee participation and standard work. teamwork skills and flexibility are improved between.

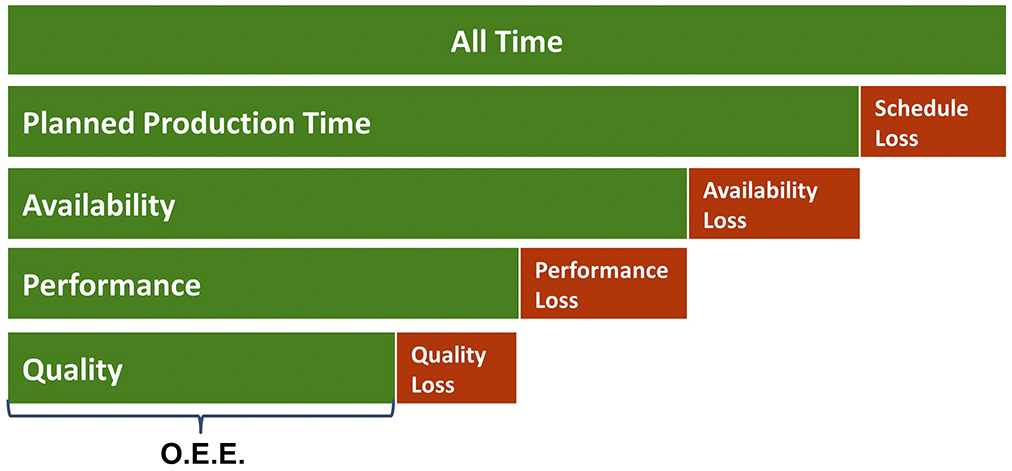

Overall Equipment Effectiveness O E E Kaufman Global Calculation Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. an oee score of 100% represents perfect production: manufacturing only good parts, as fast as possible, with no downtime. oee is useful as both a benchmark and a baseline:. Overall equipment effectiveness | o.e.e. overall equipment effectiveness (o.e.e) measures the time that an asset (machine) is producing product versus the theoretical maximum amount of time the equipment could be producing. What is oee? oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. simply put – it identifies the percentage of manufacturing time that is truly productive. an oee score of 100% means you are manufacturing only good parts, as fast as possible, with no stop time. Overall equipment effectiveness. overall equipment effectiveness[1] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared to its full potential, during the periods when it is scheduled to run. it identifies the percentage of manufacturing time that is truly productive.

Comments are closed.