Overall Equipment Effectiveness Guide To Oee In Indutry 4 0

Overall Equipment Effectiveness Guide To Oee In Indutry 4 Conclusion. overall equipment effectiveness is like a report card for your machine or automation process in the industrial automation and industry 4.0 world. it’s how process engineers, plant managers and continuous improvement engineers measure how well their automation or process is working. oee is an extremely useful calculation tool used. Overall equipment effectiveness is a crucial key performance indicator in the manufacturing sector, offering insights into the efficiency and effectiveness of machinery and production lines. this metric is made up of three core components: availability, performance, and quality, each providing a unique lens to assess equipment’s operational success. oee not only aligns with the principles….

Measuring Industry 4 0 Through Oee Overall Equipment Effectiv This gives 100 133 40 = 273minutes. this also means that the cnc machine ran optimally for (500 – 273) 227 minutes. using the oee calculations you get availability (80%) performance (66.7%) quality (85%) = 45%. this oee calculation shows that the overall equipment effectiveness was 45%. Oee chart. oee is a perfect fit within the concept of industry 4.0. it is the metric that measures the effectiveness of implementation of industry 4.0 philosophies, which as we have said in the past include: real time condition monitoring. your machines and sensor data are recorded and displayed in real time, providing the basis for real time. Future of oee. role of oee in industry 4.0 era. as manufacturers pivot towards industry 4.0, oee will become increasingly intertwined with advanced technologies. it will serve as a vital metric for 'smart factories' with highly automated and interconnected operations. utilisation of smart technologies for oee enhancement. artificial. Pdf | overall equipment effectiveness (oee) is a key performance indicator used to measure equipment productivity. in the industry 4.0 framework, the digitalization of the production process.

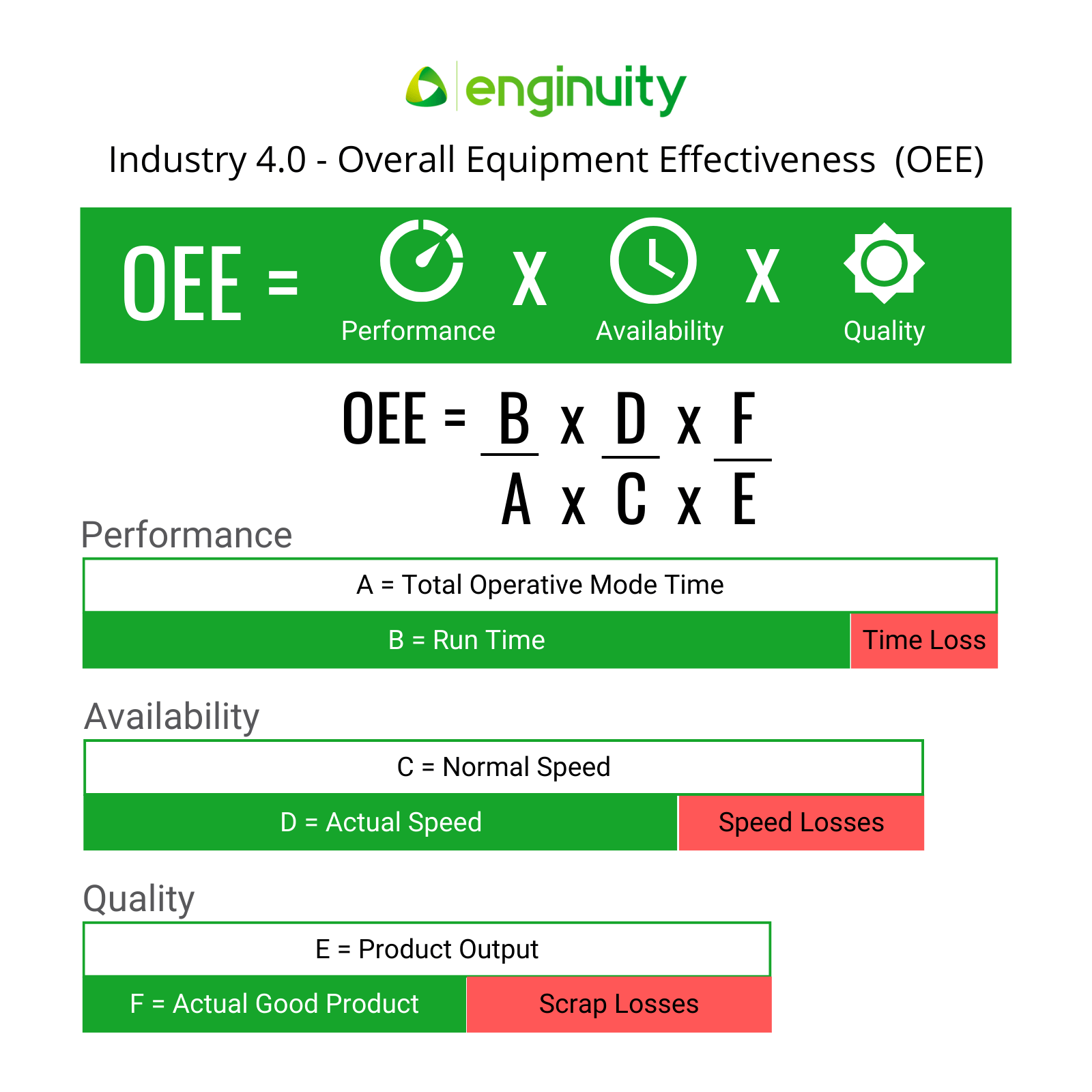

Overall Equipment Effectiveness Guide To Oee In Indutry 4 Future of oee. role of oee in industry 4.0 era. as manufacturers pivot towards industry 4.0, oee will become increasingly intertwined with advanced technologies. it will serve as a vital metric for 'smart factories' with highly automated and interconnected operations. utilisation of smart technologies for oee enhancement. artificial. Pdf | overall equipment effectiveness (oee) is a key performance indicator used to measure equipment productivity. in the industry 4.0 framework, the digitalization of the production process. Overall equipment effectiveness (oee) is a powerful metric used in manufacturing to measure the efficiency and effectiveness of a production process. understanding and improving oee can lead to significant gains in productivity, cost savings, and overall operational performance. Oee = availability x performance x quality. the result is a percentage value that indicates the overall effectiveness of the equipment or process. a higher oee percentage indicates better performance and effectiveness, while a lower percentage suggests room for improvement. oee is commonly used as a performance metric in manufacturing.

Calculating Overall Effective Equipment Oee Clearmark Overall equipment effectiveness (oee) is a powerful metric used in manufacturing to measure the efficiency and effectiveness of a production process. understanding and improving oee can lead to significant gains in productivity, cost savings, and overall operational performance. Oee = availability x performance x quality. the result is a percentage value that indicates the overall effectiveness of the equipment or process. a higher oee percentage indicates better performance and effectiveness, while a lower percentage suggests room for improvement. oee is commonly used as a performance metric in manufacturing.

Comments are closed.