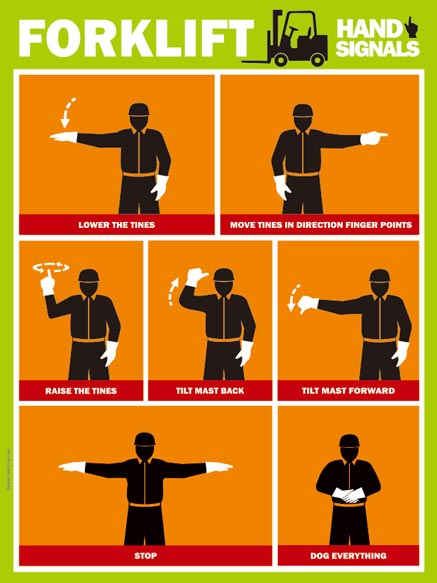

Osha Forklift Hand Signals Chart

Forklift Hand Signals Safety Poster Shop Graphs and tables like the one below can help with memorization — they summarize each hand signal in an easy to follow movement. forklift accidents represent some of the worst hazards employees face on a job site. but thanks to osha’s forklift hand signals, spotters can ensure an entire crew’s safety. these signals won’t only protect. Forklift hand signals emergency stop stop stop engine pause everything raise load lower load raise load slowly lower load slowly this far to go tilt forks up tilt forks down the operator must only respond to signals from the designated signaller. the only exception is if anyone gives the emergency stop signal, the operator must follow it.

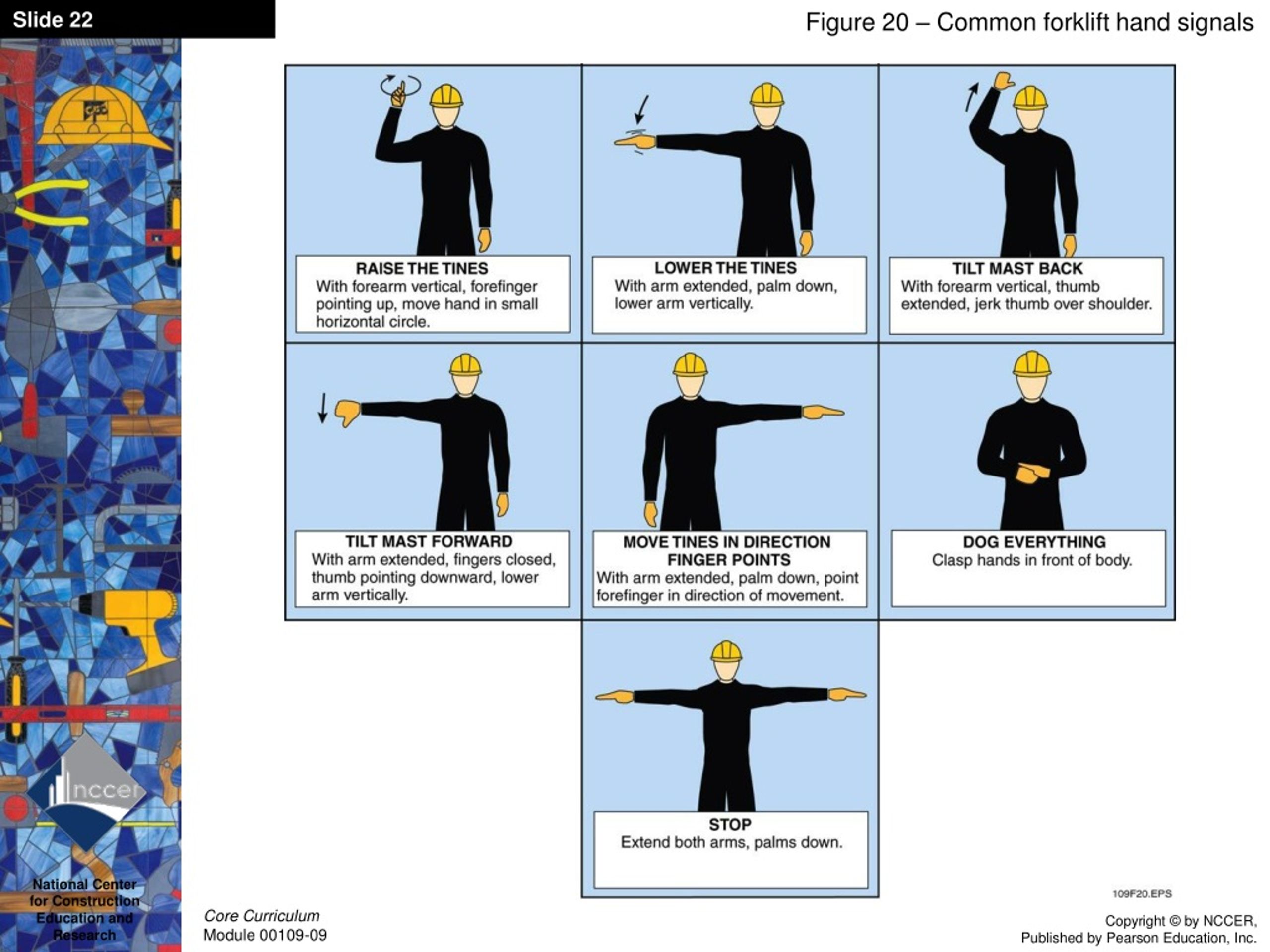

Forklift Hand Signals Chart Note: the operator should respond to signals only from the designated signaler, but only the stop signal no matter who gives it. tilt mast back with forearm vertical, thumb extended, jerk thumb over shoulder. dog everything clasp hands in front of body. provided by: forkliftsafety ]a 1 800 494 3225 forkliftsafety. Forklift hand signals allow for clear communication between an operator and a forklift spotter, even in the loudest work environments. that’s important because forklift accidents are too common. according to the national safety council, in 2020, forklifts were the source of 78 work related deaths and 7,290 nonfatal injuries involving days away from work. Like many of the osha forklift hand signals, the gesture for raising the tines is simple. raise the right hand, pointing up, with the elbow at 90 degrees and the index finger pointed to the ceiling or sky. the finger then rotates in a small circle until the tines have reached the correct height. 4. lower the tines. 1926.1419 (a) (2) when the equipment is traveling, the view in the direction of travel is obstructed. 1926.1419 (a) (3) due to site specific safety concerns, either the operator or the person handling the load determines that it is necessary. 1926.1419 (b) types of signals. signals to operators must be by hand, voice, audible, or new signals.

19 Osha Forklift Hand Signals Chart Background Forklift Reviews Like many of the osha forklift hand signals, the gesture for raising the tines is simple. raise the right hand, pointing up, with the elbow at 90 degrees and the index finger pointed to the ceiling or sky. the finger then rotates in a small circle until the tines have reached the correct height. 4. lower the tines. 1926.1419 (a) (2) when the equipment is traveling, the view in the direction of travel is obstructed. 1926.1419 (a) (3) due to site specific safety concerns, either the operator or the person handling the load determines that it is necessary. 1926.1419 (b) types of signals. signals to operators must be by hand, voice, audible, or new signals. Emergency forklift hand signals: dog everything (this means pause immediately) stop (different than dog everything, stop means emergency stop) important: you won’t be watching the forklift operator, you will be watching the load–and the forklift operator will be watching for your hand signals. osha requires forklift retraining every 3 years. Standard number: 1926.1422. title: signals hand signal chart. gpo source: e cfr. hand signal charts must be either posted on the equipment or conspicuously posted in the vicinity of the hoisting operations. [75 fr 48153, august 9, 2010] osha.

Download Forklift Hand Signal Chart Images Forklift Reviews Emergency forklift hand signals: dog everything (this means pause immediately) stop (different than dog everything, stop means emergency stop) important: you won’t be watching the forklift operator, you will be watching the load–and the forklift operator will be watching for your hand signals. osha requires forklift retraining every 3 years. Standard number: 1926.1422. title: signals hand signal chart. gpo source: e cfr. hand signal charts must be either posted on the equipment or conspicuously posted in the vicinity of the hoisting operations. [75 fr 48153, august 9, 2010] osha.

Osha Hand Signals For Forklifts

Comments are closed.