Open Cooling Tower Piping Diagram

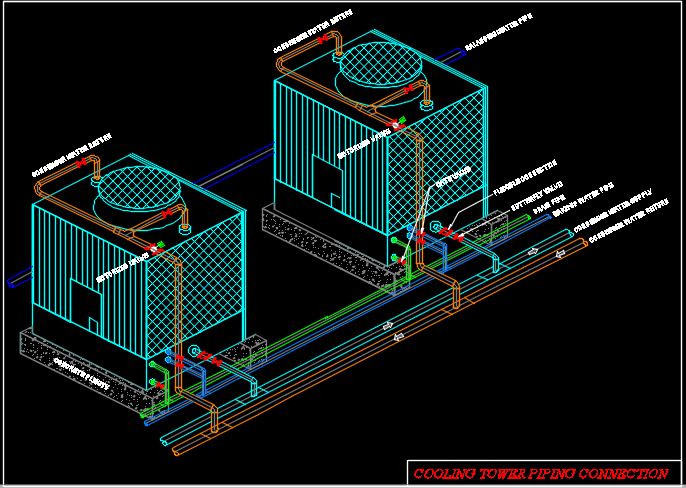

Cooling Tower Piping Schematic Diagram Condenser water return pipework [1] the cooling tower return pipework is installed to transport the warm water from the condenser side of the water cooled chiller to the cooling tower, with the flow being provided by the condenser water pumps that are installed on the supply side of the tower [tower to chiller] to move the water around the system. C sfigure 2 open piping circuitin figure 2, the required pump head will be the pipe flow friction loss from a to d plus the energy head (h s) required to raise wate. from the lower to higher level.the cooling tower circuit differs slightly from the basic “open” circuit in that the discharge piping is connected d.

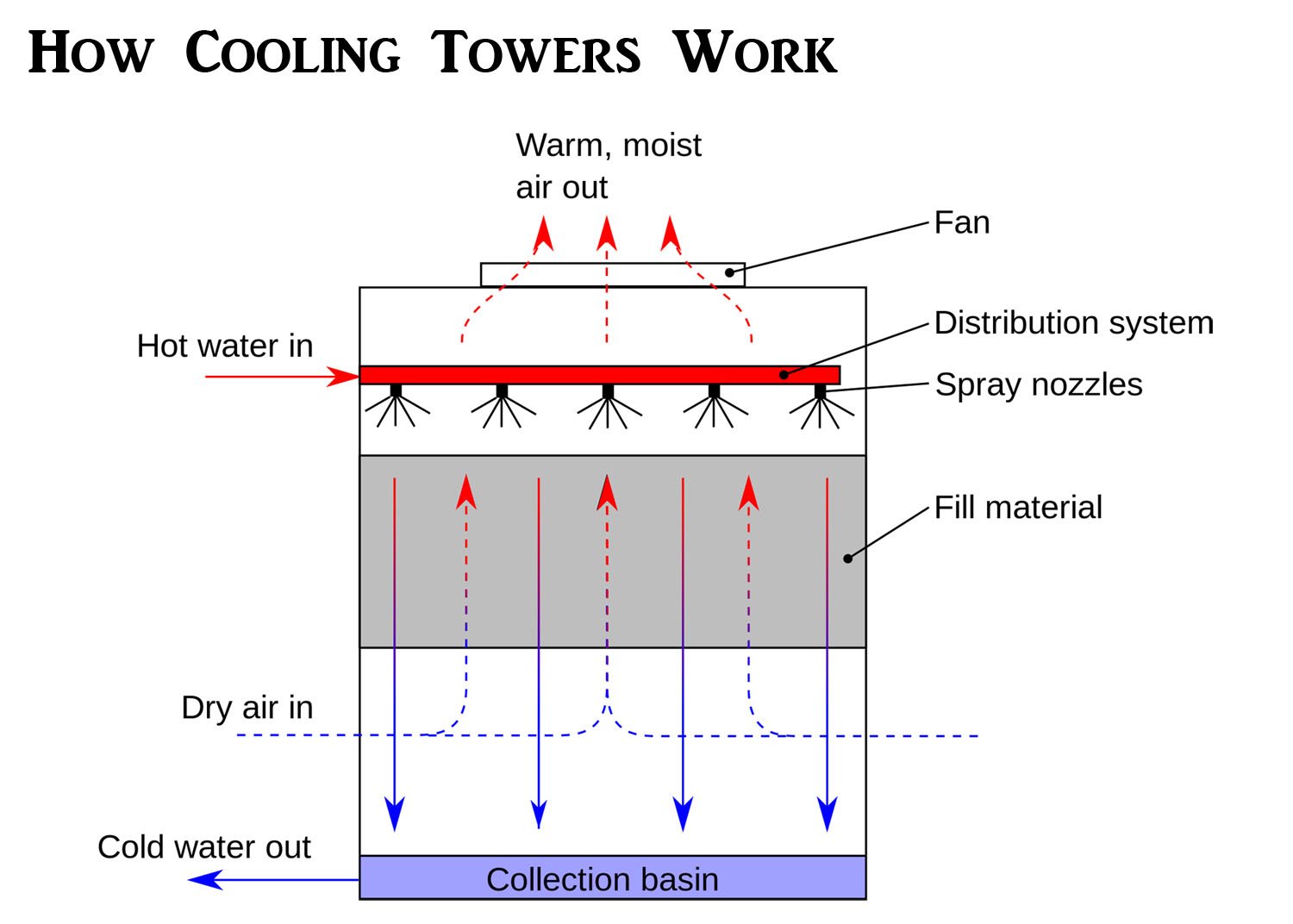

Cooling Tower Piping Schematic Diagram Cooling tower piping: when designing a cooling tower system for free cooling applications, several piping details should be considered to ensure proper winter operation of the unit. a cooling tower bypass needs to be incorporated into the system design to allow water to “bypass” the tower’s water distribution system as a means of capacity. In the design and operation of cooling towers, a piping schematic plays a crucial role in ensuring the efficient and effective cooling of water. this schematic provides a detailed representation of the piping system within a cooling tower, including the flow paths, pipe sizes, valves, and other components. it serves as a roadmap for engineers. Evaporative cooling towers exploit a simple and natural physical principle: forced evaporation of a minimal water quantity lowers the temperature of the main. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the.

Open Circuit Cooling Tower Diagram Evaporative cooling towers exploit a simple and natural physical principle: forced evaporation of a minimal water quantity lowers the temperature of the main. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. The air drawn through this cascading water provides evaporative cooling similar to an open cooling tower, except that the cooled water never makes direct contact with the air. closed circuit cooling towers require much more energy to achieve the same cooling as an open circuit cooling tower. different types of closed circuit cooling tower systems.

Cooling Tower Piping Schematic Diagram Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. The air drawn through this cascading water provides evaporative cooling similar to an open cooling tower, except that the cooled water never makes direct contact with the air. closed circuit cooling towers require much more energy to achieve the same cooling as an open circuit cooling tower. different types of closed circuit cooling tower systems.

Comments are closed.