Mig Mag Braze Welding 4 Download Scientific Diagram

Mig Mag Braze Welding 4 Download Scientific Diagram Download scientific diagram | mig mag braze welding [4] from publication: influence of the shielding gas on the properties of vp mig mag braze welded joints in zinc coated steel sheets | the. Download scientific diagram | test rig for braze welding (left), a dw 300 welding device by daihen (right) from publication: influence of the shielding gas on the properties of vp mig mag braze.

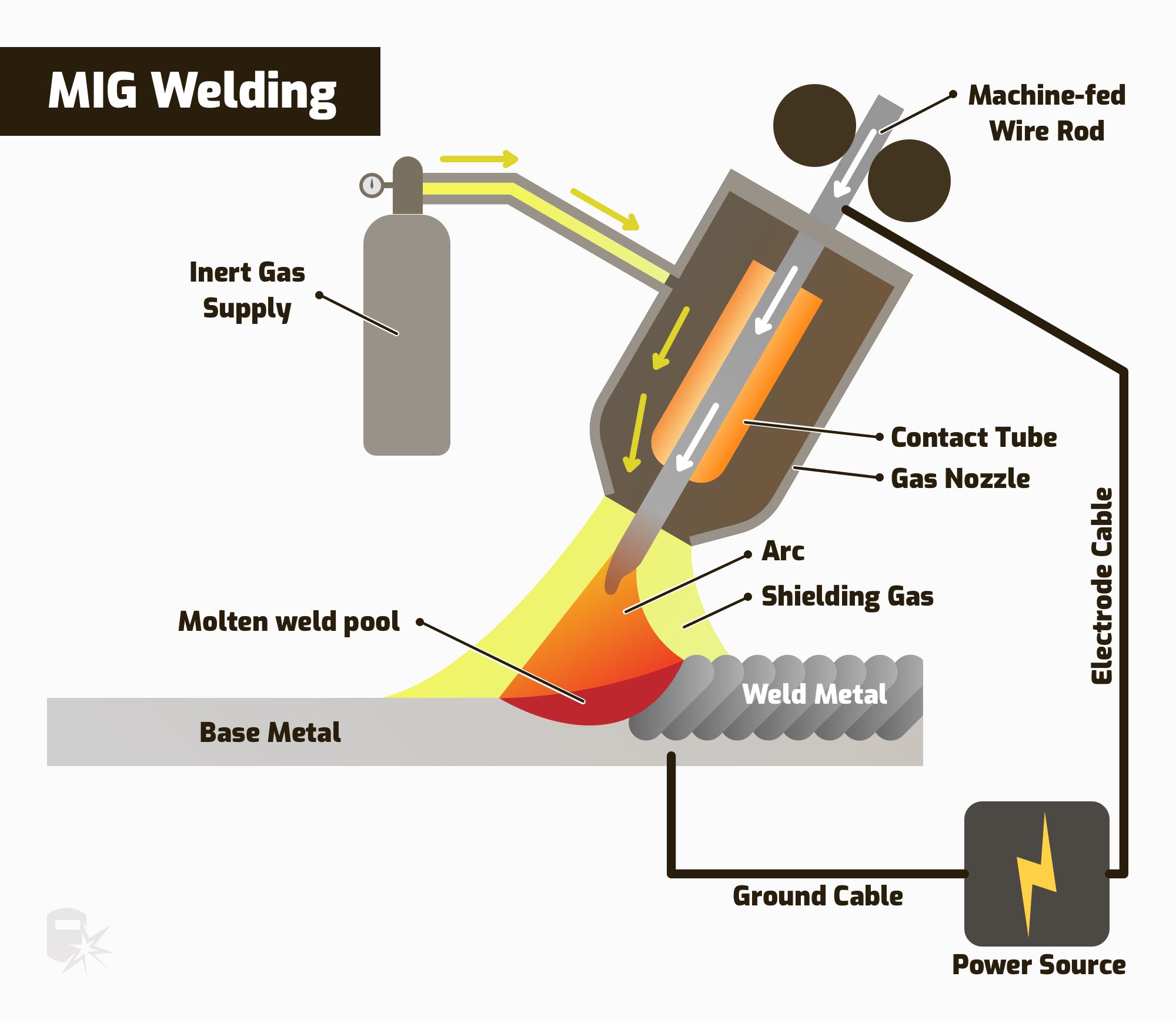

4 Main Types Of Welding Processes With Diagrams The wire, the welding pool and the hot metal are protected against the harmful atmosphere influence by shielding environment [5] of inert gas in the case of mig welding, and active gas. The process of braze welding is a variable of the mig mag welding process. the majority of braze welding’s essential variables resemble those of the conventional mig mag welding processes. however, the melting points of filler wires are different between the two welding processes. in braze welding, a continuously fed wire electrode is melted. The braze welding process is a variant of the mig mag welding process, where the majority of the process essential variables are identical to conventional mig mag welding processes. however, in the braze welding process, the melting point of the filler wires is significantly lower with relation to the melting point of the parent material. Braze welding is defined as the brazing of non capillary joints performed using weld ing methods [1 3]. this means that elements to be joined are prepared as if for welding, i.e. without a capillary gap (characteristic of braz ing processes), the width of which is usually restricted within the range of 0.05 to 0.2 mm.

Comments are closed.