Micromachines Free Full Text Cu Cu Thermocompression Bonding With A

Micromachines Free Full Text Cu Cu Thermocompression Bonding With A Lykova m, panchenko i, schneider ramelow m, suga t, mu f, buschbeck r. cu cu thermocompression bonding with a self assembled monolayer as oxidation protection for 3d 2.5d system integration. micromachines . 2023; 14(7):1365. Cu cu direct interconnects are highly desirable for the microelectronic industry as they allow for significant reductions in the size and spacing of microcontacts. the main challenge associated with using cu is its tendency to rapidly oxidize in air. this research paper describes a method of cu passivation using a self assembled monolayer (sam) to protect the surface against oxidation. however.

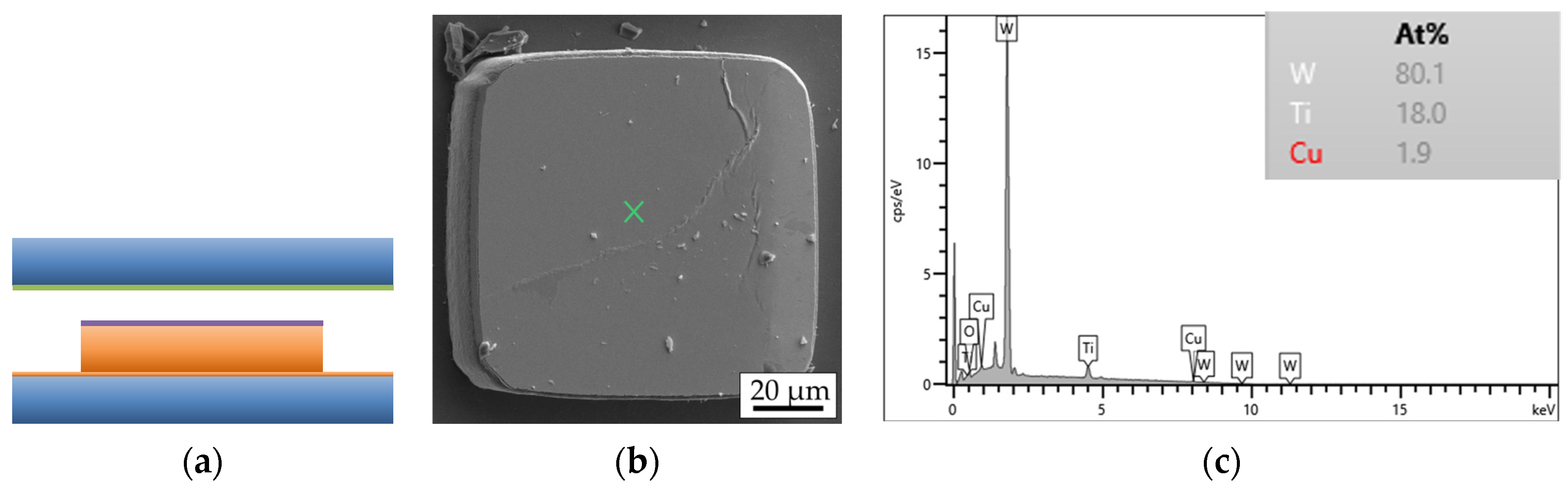

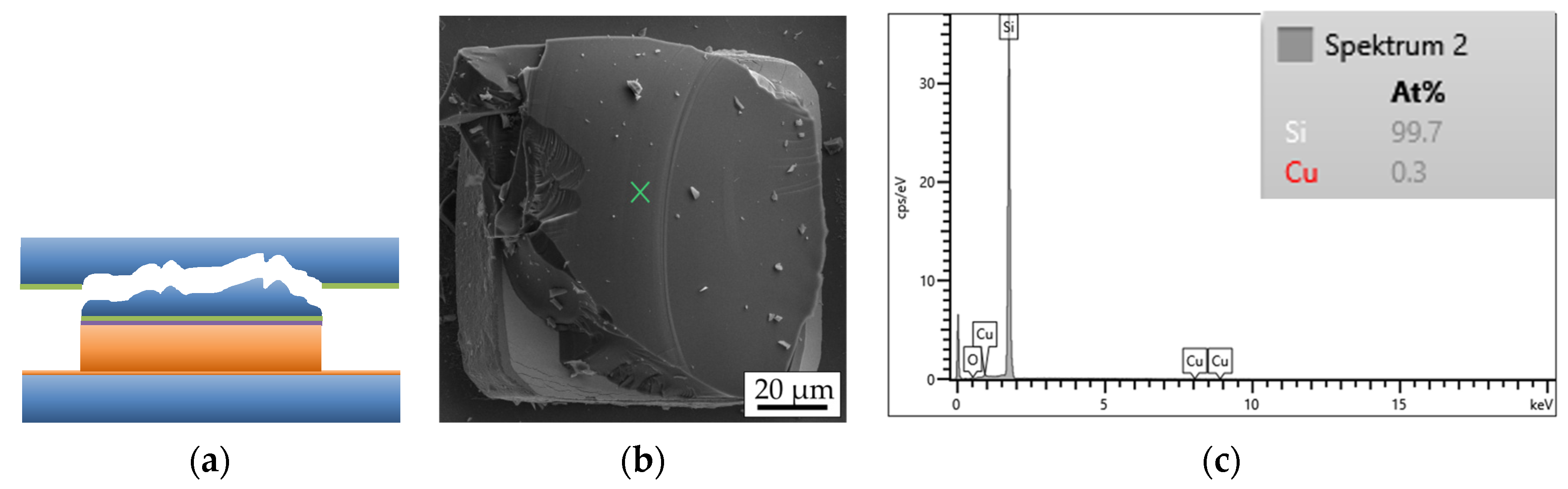

Micromachines Free Full Text Cu Cu Thermocompression Bonding With A Cu cu thermocompression bonding with a self assembled monolayer as oxidation protection for 3d 2.5d system integration download full text pdf read full text. micromachines 2023, 14, 1365. Micromachines 2023, 14, 1365 3 of 19 smooth, sputtered surfaces are commonly recommended for sam passivation [21], but cu microbumps are typically electroplated and have a greater roughness than those. The applied thermocompression bonding technique can be described as follows. bonding was carried out in the n 2 purged bonding chamber of the alpha design tc bonder. table 2 shows the main bonding parameters used in these experiments. initially, the top die was placed face down in the center of the face up bottom die lying on a heating stage in. To increase the yield of the wafer level cu cu thermo compression bonding method, certain surface pre treatment methods for cu are studied which can be exposed to the atmosphere before bonding. to inhibit re oxidation under atmospheric conditions, the reduced pure cu surface is treated by h2 ar plasma, nh3 plasma and thiol solution, respectively, and is covered by cu hydride, cu nitride and a.

Micromachines Free Full Text Cu Cu Thermocompression Bonding With A The applied thermocompression bonding technique can be described as follows. bonding was carried out in the n 2 purged bonding chamber of the alpha design tc bonder. table 2 shows the main bonding parameters used in these experiments. initially, the top die was placed face down in the center of the face up bottom die lying on a heating stage in. To increase the yield of the wafer level cu cu thermo compression bonding method, certain surface pre treatment methods for cu are studied which can be exposed to the atmosphere before bonding. to inhibit re oxidation under atmospheric conditions, the reduced pure cu surface is treated by h2 ar plasma, nh3 plasma and thiol solution, respectively, and is covered by cu hydride, cu nitride and a. Cu cu direct interconnects are highly desirable for the microelectronic industry as they allow for significant reductions in the size and spacing of microcontacts. the main challenge associated with using cu is its tendency to rapidly oxidize in air. this research paper describes a method of cu passivation using a self assembled monolayer (sam) to protect the surface against oxidation. however. Illustration of the tack and collective bonding approach: (1) 300 mm handle wafer coated with sacrificial adhesive, (2) chip tack bonding to handle wafer using a high accuracy die bonder, (3) collective thermocompression bonding where heat and force are applied across all chips in parallel forming the pad to pillar cu cu bonds, and (4.

Micromachines Free Full Text Cu Cu Thermocompression Bonding With A Cu cu direct interconnects are highly desirable for the microelectronic industry as they allow for significant reductions in the size and spacing of microcontacts. the main challenge associated with using cu is its tendency to rapidly oxidize in air. this research paper describes a method of cu passivation using a self assembled monolayer (sam) to protect the surface against oxidation. however. Illustration of the tack and collective bonding approach: (1) 300 mm handle wafer coated with sacrificial adhesive, (2) chip tack bonding to handle wafer using a high accuracy die bonder, (3) collective thermocompression bonding where heat and force are applied across all chips in parallel forming the pad to pillar cu cu bonds, and (4.

Comments are closed.