Marking Tools Steel Rule Divider Trammel Punch Sheet Metal

Marking Tools Steel Rule Divider Trammel Punch Sheet Metal 4. marking and measuring tools: (steel rule, scriber, trammel, divider, swing blade protractor, wire gauge) a) steel rule: it is used for linear measurements up to the accuracy of 0.5 mm. b) scribers: it is made up of hardened steel with pointed end used for marking lines on the sheet. Hello friends,in this topic we will study about the marking tools used in sheet metal shop. these tools used widely in engineering application. following top.

List Of 18 Marking Tools Their Uses Names Pictures Pdf A prick punch is a layout marking tool that is made of carbon steel and has a length of about 100mm to 150mm. both ends of the punch are made hard and temper. the pointed tip of this punch is ground at an angle of 30° to 60°. these types of marking tools are commonly used to mark jobs of thin metal sheets or to make holes in them. Here in this article we are going to have the list of sheet metal tools names and images as well. types of sheet metal tools. there are fairly large number of hand tools used by sheet metal workers. the tools most commonly used are : a. measuring tools 1. steel rule . this is particularly useful in measuring and laying out small work. Some common tools are: scriber, flat steel square, combination square, protractor, prick punch, dividers, trammel points, and circumference rule. scriber lines are scribed on sheet metal with a scratch awl, coupled with a steel scale or a straightedge. for best results, hold the scale or straightedge firmly in place. Marking out takes place before cutting, shaping, drilling or just about doing anything on a piece of sheet metal. marking out is the transferring of the dimensions from the plan to the work piece in preparation for the next step of machining manufacture. typical marking tools include: surface plate or marking out table , scriber, dividers,.

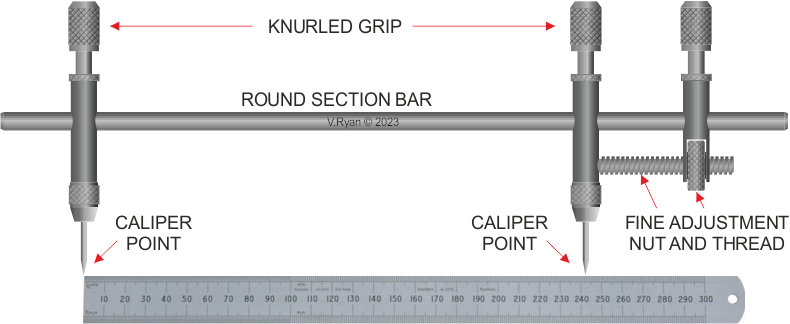

Sheet Metal Marking Tools Some common tools are: scriber, flat steel square, combination square, protractor, prick punch, dividers, trammel points, and circumference rule. scriber lines are scribed on sheet metal with a scratch awl, coupled with a steel scale or a straightedge. for best results, hold the scale or straightedge firmly in place. Marking out takes place before cutting, shaping, drilling or just about doing anything on a piece of sheet metal. marking out is the transferring of the dimensions from the plan to the work piece in preparation for the next step of machining manufacture. typical marking tools include: surface plate or marking out table , scriber, dividers,. Using a trammel to scribe an arc on the surface of sheet metal, is shown below. a centre punch ‘indentation’, is at the centre of the arc, ensuring that the trammel does not slip on the surface, during scribing. photo realistic image : this diagram shows a trammel being used, to determine the distance between two points of an engine component. A prick punch is a layout marking tool or marking out tools that are made of steel, approximately 100 mm to 150 mm. it is long, with both ends hard and tempered. its point is grinded at an angle of 30 ° to 60 °. it is used to place small dots on layout lines, punch marks on the center of drill holes. center punch.

Trammels For Engineering Using a trammel to scribe an arc on the surface of sheet metal, is shown below. a centre punch ‘indentation’, is at the centre of the arc, ensuring that the trammel does not slip on the surface, during scribing. photo realistic image : this diagram shows a trammel being used, to determine the distance between two points of an engine component. A prick punch is a layout marking tool or marking out tools that are made of steel, approximately 100 mm to 150 mm. it is long, with both ends hard and tempered. its point is grinded at an angle of 30 ° to 60 °. it is used to place small dots on layout lines, punch marks on the center of drill holes. center punch.

Comments are closed.