Maintenance The Implications Of Iot And Industry 4 0 On Key

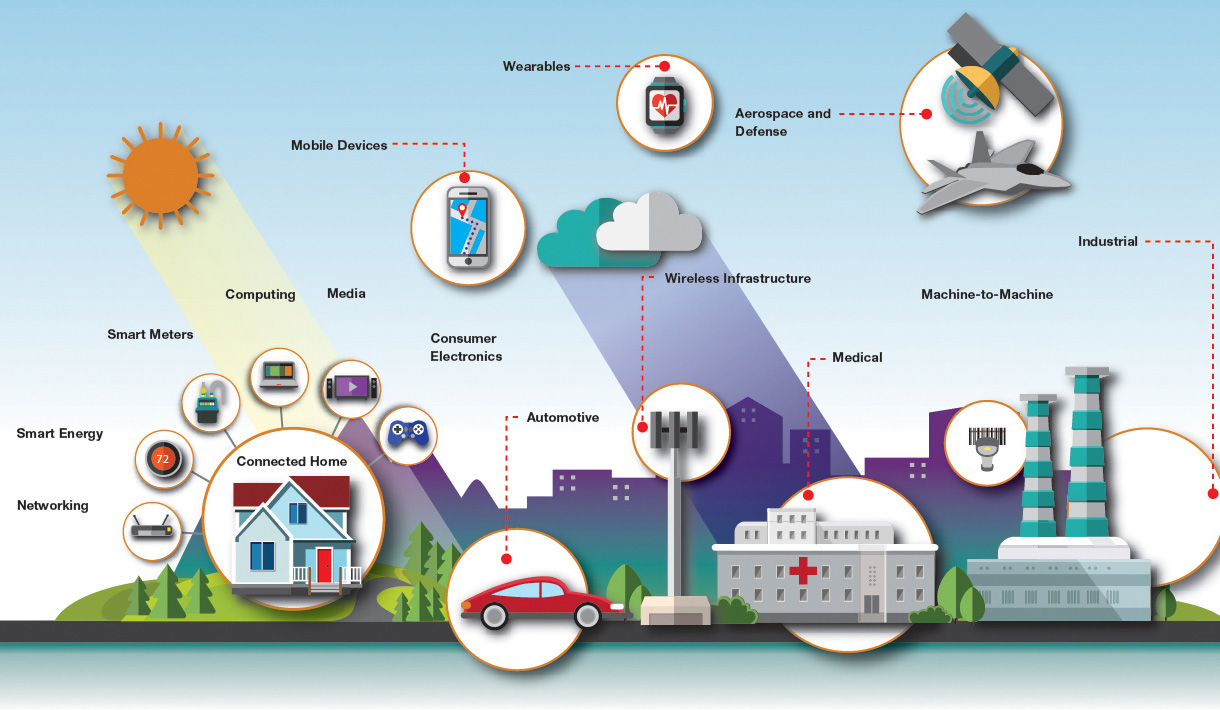

Maintenance The Implications Of Iot And Industry 4 0 On Keyођ Iot as envisioned will permit economical communication at any time, at any place and with anything, whilst taking care of security and privacy in a greatly enhanced next generation global wireless data network. on the other hand, industry 4.0 is more conceptual and refers to the 4th industrial revolution, which is going on today. The internet of things (iot) is playing a significant role in the transformation of traditional factories into smart factories in industry 4.0 by using network of interconnected devices, sensors, and software to monitor and optimize the production process. predictive maintenance using the iot in smart factories can also be used to prevent.

What Is Industry 4 0 Here S Everything You Need To Know 2022 In the past five years, a select group of companies have started pulling ahead in their efforts to implement industry 4.0 across their manufacturing networks. leading manufacturers are now realizing significant value from data and analytics, ai, and machine learning (ml). however, a large majority remain stuck in pilot purgatory, struggling to. Abstract. industry 4.0 is strongly intertwined with big data streaming flows from intelligent sensors and machinery installed in industrial facilities. failures can disrupt production and lead the supply chain ecosystem to malfunction. maintenance strategies are necessary to safeguard the continuous operation of production lines, minimize. In the era of the fourth industrial revolution, several concepts have arisen in parallel with this new revolution, such as predictive maintenance, which today plays a key role in sustainable manufacturing and production systems by introducing a digital version of machine maintenance. the data extracted from production processes have increased exponentially due to the proliferation of sensing. Industry 4.0, also known as the fourth industrial revolution, represents a significant transformation in the world of manufacturing and industry. it is characterized by the integration of digital technologies into industrial processes with the primary aim of improving manufacturing responsiveness, quality, and efficiency.

Comments are closed.