Lean Production Introduction

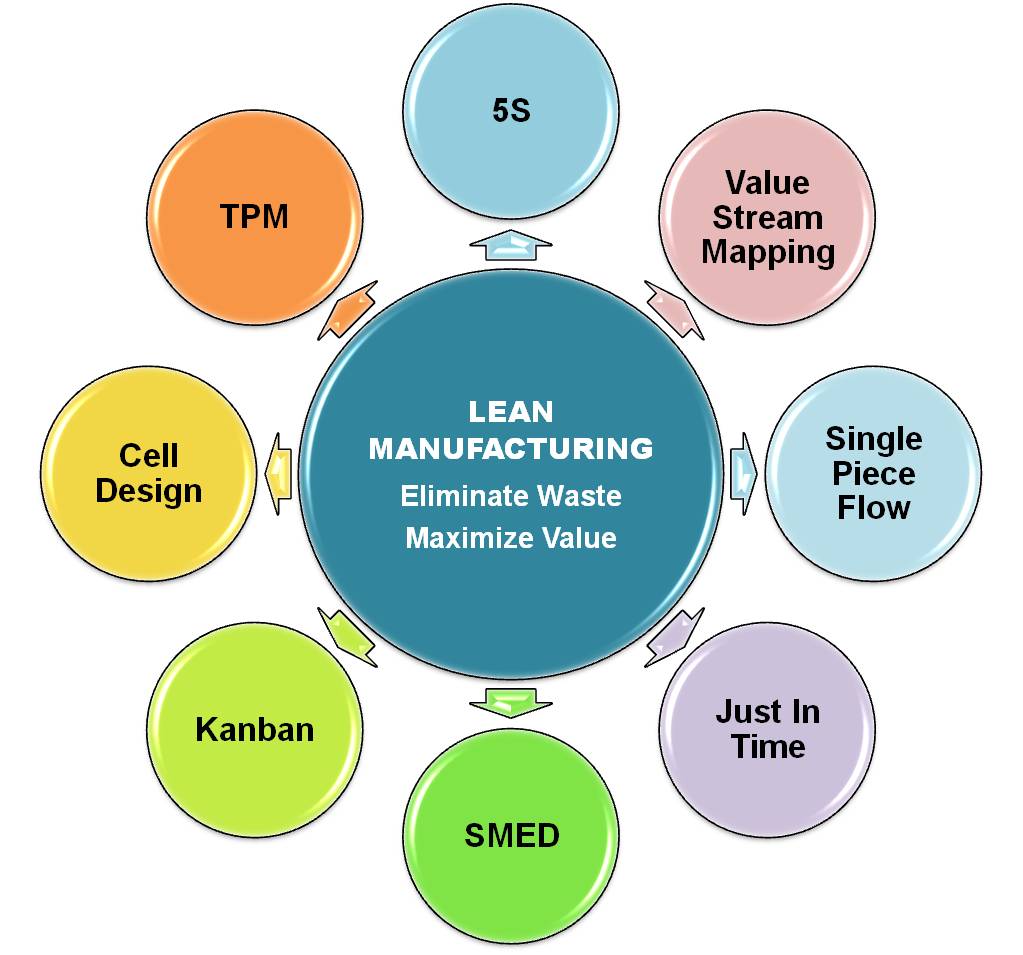

Lean Manufacturing Lean Principles Lean 5s According to research conducted by the lean enterprise research centre (lerc), fully 60% of production activities in a typical manufacturing operation are waste – they add no value at all for the customer. the good news is that just about every company has a tremendous opportunity to improve by eliminating waste, using lean manufacturing. Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands.

Lean Manufacturing 101 The Why What And How Hms Blog The introduction of the lean approach involves focusing on waste reduction, value creation, and continuous improvement in the manufacturing process. what does six sigma mean? six sigma is a data driven and statistical methodology used to improve processes, reduce defects, and enhance the quality of products and services. Machine industry. lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. it is closely related to another concept called just in time manufacturing (jit manufacturing in short). Lean production (introduction) lean production is an approach to management that focuses on cutting out waste, whilst ensuring quality. this approach can be applied to all aspects of a business – from design, through production to distribution. lean production aims to cut costs by making the business more efficient and responsive to market needs. Implementing lean manufacturing principles in workforce management yields numerous benefits, including: improved efficiency and productivity: by eliminating waste and optimizing processes, lean facilitates smoother operations, leading to increased productivity. enhanced quality control: lean emphasizes defect prevention and quality at the.

Comments are closed.