Lean Principles Qcfi Quality Circle Lqc 5s Kaizen Total

Lean Principles Qcfi Quality Circle Lqc 5s Kaizen Total 46th international convention on quality control circles – 2021 (icqcc 2021) hyderabad, certificate awarded to bpcl, ongole for successful implementation of 5s on the genesis of quality circles. Notice: quality circle forum of india that the 41st annual general meeting (agm) on 30th september, 5pm at hotel yois, roop sagar, udaipur new initiative: offshore convention 2024 pattaya, thailand first announcement 38th national convention on quality concepts 2024 (ncqc 2024) organized by qcfi in association with abv iiitm, gwalior from 27th.

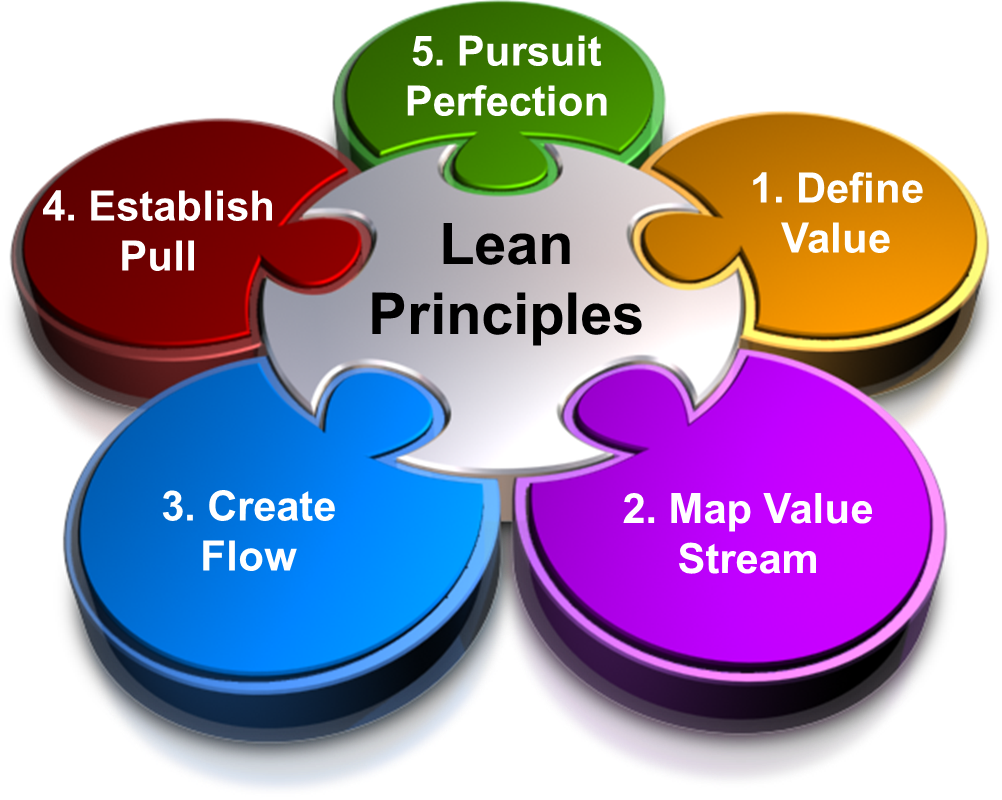

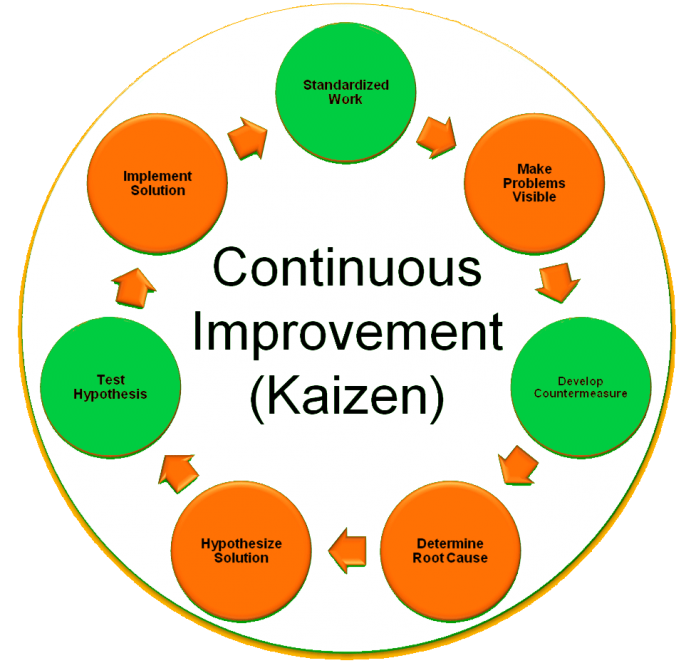

10 Things To Avoid During A Kaizen Qcfi Quality Circle Lqc 5s ‘quality circles concept’ started in 1962 in japan as quality control circles and since 1982, india is practicing. this made mr. d k srivastava, executive director, qcfi to evolve a new concept – lean quality circle (lqc) and presented in the board meeting held march, 2010. History and development. the concept of quality circles originated in japan during the 1960s, primarily through the efforts of dr. kaoru ishikawa and his associates. initially implemented in manufacturing environments, quality circles have since evolved to encompass various industries worldwide, becoming an integral part of lean methodologies. Kaizen, with its commitment to continuous improvement and the involvement of all employees, significantly strengthens lean management principles. this philosophy introduces a dynamic of constant improvement into lean, essential for sustaining its benefits. through the small innovations encouraged by kaizen, lean processes become more efficient. The 4ms of essential reliability represent the following elements — manpower, machines, materials, and methods — and are fundamental in many production systems and quality management. within lean production and kaizen philosophy, the 4ms are critical aspects that should be analyzed and optimized to ensure efficiency and quality.

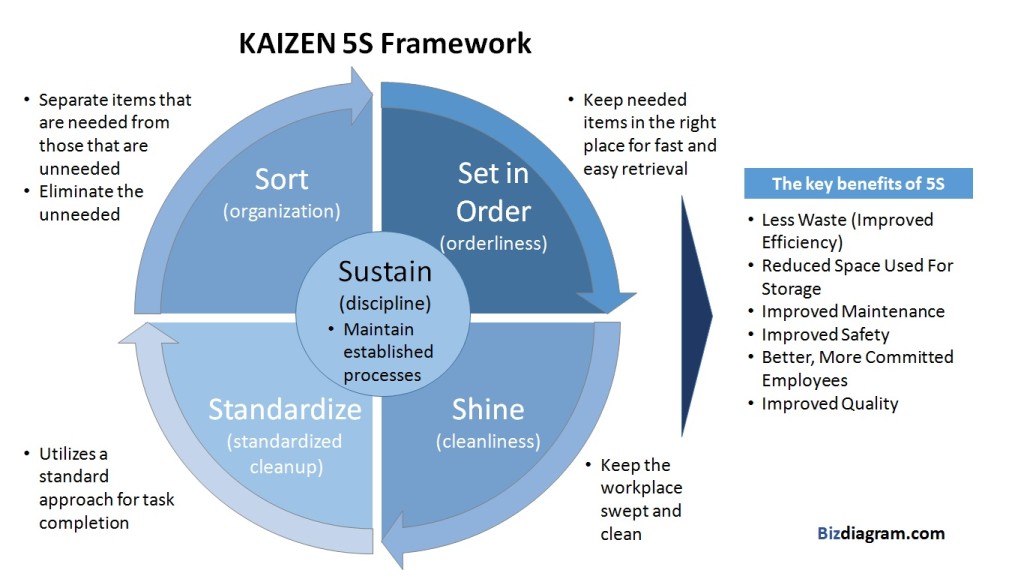

Kaizen Smed Competition Qcfi Quality Circle Lqc 5s Kaizen Kaizen, with its commitment to continuous improvement and the involvement of all employees, significantly strengthens lean management principles. this philosophy introduces a dynamic of constant improvement into lean, essential for sustaining its benefits. through the small innovations encouraged by kaizen, lean processes become more efficient. The 4ms of essential reliability represent the following elements — manpower, machines, materials, and methods — and are fundamental in many production systems and quality management. within lean production and kaizen philosophy, the 4ms are critical aspects that should be analyzed and optimized to ensure efficiency and quality. What are the principles of 5s? 5s is a philosophy applied in the workplace that helps promote efficiency and effectiveness. as one of the core principles of kaizen, 5s lean principles can help identify and eliminate wastage to achieve a well organized and safe working environment. a cluttered and untidy workplace can lead to low productivity. Adherence to 5s standards is considered the foundation of total productive maintenance (tpm) and an integral part of the toyota production system (tps). 5s also creates a stable platform from which kaizen activities can be launched. the bottom line 5s is a low investment, high impact lean manufacturing tool that is predicated on people.

Qcfi 41st Annual General Meeting Qcfi Quality Circle Lqc 5s What are the principles of 5s? 5s is a philosophy applied in the workplace that helps promote efficiency and effectiveness. as one of the core principles of kaizen, 5s lean principles can help identify and eliminate wastage to achieve a well organized and safe working environment. a cluttered and untidy workplace can lead to low productivity. Adherence to 5s standards is considered the foundation of total productive maintenance (tpm) and an integral part of the toyota production system (tps). 5s also creates a stable platform from which kaizen activities can be launched. the bottom line 5s is a low investment, high impact lean manufacturing tool that is predicated on people.

5s Kaizen Principles

Comments are closed.