Lean Manufacturing Pull System

Pull Production System Lean Six Sigma Training Guide Copy The pull system is an integral concept in inventory and production management, deeply rooted in the philosophy of lean manufacturing. this approach fundamentally shifts the focus from the traditional forecast driven production strategies to a more demand responsive model. the pull system initiates the production and movement of goods based. A pull system is a fundamental principle of lean manufacturing that aims to minimize waste in production processes. by aligning production with actual customer demand, this approach ensures that components are replenished only when out of stock, leading to optimized resource utilization, improved flow efficiency, and reduced inventory levels.

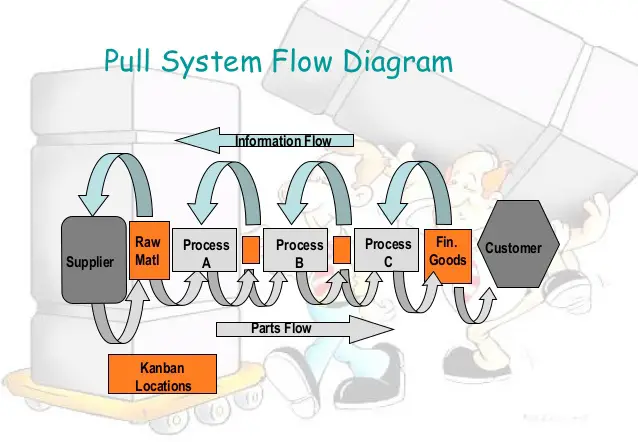

Lean Manufacturing Pull Systems Youtube March 27, 2024. 4:53 pm. the pull system in lean manufacturing turns the traditional production model on its head, focusing on demand driven operations rather than forecast based planning. by optimizing inventory levels and reducing waste, it offers a clear pathway to improved efficiency and sustainability in manufacturing processes. The pull system is an integral part of lean manufacturing. its main goal is to create a workflow where work begins only when the customer requests it. when implementing the pull system, it’s essential to understand how it differs from the push system. pull systems generally have three types: a, b, and c, each with advantages. A pull system is a lean manufacturing process used in the production process to reduce waste. ingredients or components used in the manufacturing process are replaced after being consumed; companies make products that will meet customer demands. this means all the company resources will be used for the production of goods that will be sold. The principles of lean aim to streamline production, reduce waste, and ultimately deliver value to the customer. among these principles, the concepts of “push,” “pull,” and “flow” are foundational. these strategies dictate how products and information move through a manufacturing system, influencing everything from inventory.

Lean Manufacturing Six Sigma Pull Production Systems з џз јг г гѓ гѓ г еј гѓ A pull system is a lean manufacturing process used in the production process to reduce waste. ingredients or components used in the manufacturing process are replaced after being consumed; companies make products that will meet customer demands. this means all the company resources will be used for the production of goods that will be sold. The principles of lean aim to streamline production, reduce waste, and ultimately deliver value to the customer. among these principles, the concepts of “push,” “pull,” and “flow” are foundational. these strategies dictate how products and information move through a manufacturing system, influencing everything from inventory. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. pull systems use requests for specific items from individual customers instead of having items delivered automatically or at a manager's discretion. one of the most significant benefits of this inventory management system is. Pull systems are usually seen in industries with shorter lead times. a pull system is a staple of a lean manufacturing model because it leads to lower inventory levels, less waste, and much faster response times to real time customer demand. this article will explore the fundamental differences between a push vs. pull system in manufacturing.

Synchronous Lean Manufacturing Pull System A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. pull systems use requests for specific items from individual customers instead of having items delivered automatically or at a manager's discretion. one of the most significant benefits of this inventory management system is. Pull systems are usually seen in industries with shorter lead times. a pull system is a staple of a lean manufacturing model because it leads to lower inventory levels, less waste, and much faster response times to real time customer demand. this article will explore the fundamental differences between a push vs. pull system in manufacturing.

Comments are closed.