Industry 4 0 How Do We Implement Industry 4 0 Technology Success

Industry 4 0 Technologies In Manufacturing Avalon Cnc Machine Shop In the past five years, a select group of companies have started pulling ahead in their efforts to implement industry 4.0 across their manufacturing networks. leading manufacturers are now realizing significant value from data and analytics, ai, and machine learning (ml). however, a large majority remain stuck in pilot purgatory, struggling to. Momentum for industry 4.0 is growing — one report by statista projects the market will swell from $263 billion in 2021 to $1.1 trillion by 2028. interest is surging, in part, because sensor networks are the backbone for creating feedback loops to identify hidden factories, the poorly understood processes and workarounds that drive up.

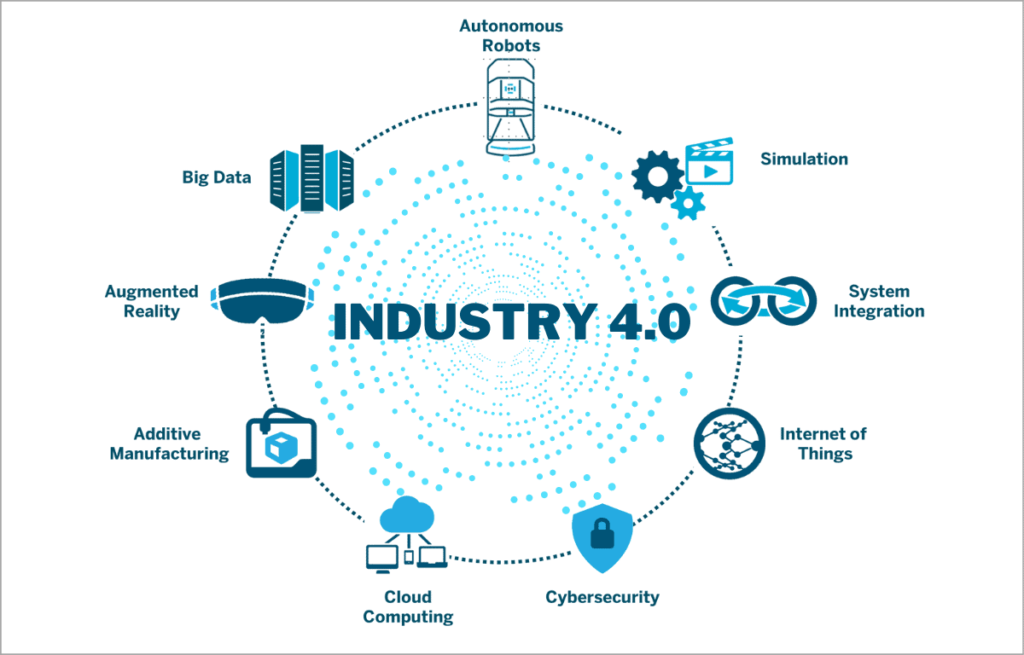

Industry 4 0 вђ How Do We Implement Industry 4 0о Industry 4.0 is the term used to refer to the fourth industrial revolution. it is a new era where connectivity, automation and digitization technology are used to optimize manufacturing and industrial processes. its great differential is the digitalization of physical assets, with sensors incorporated in practically all equipment. Industrial iot is a foundational technology of industry 4.0. the benefits of connected equipment are tremendous, as it provides insight for better decision making on many levels of the organization. a fully connected industrial operation leverages industry 4.0 technology, including iot, to gain deeper insight into performance. Industry 4.0, the fourth industrial revolution, and 4ir all refer to the current era of connectivity, advanced analytics, automation, and advanced manufacturing technology that has been transforming global business for years. this wave of change in the manufacturing sector began in the mid 2010s and holds significant potential for operations. Industry 4.0 example #3: electronic batch records. in a paper driven biopharma facility (digital plant maturity model, or dpmm, level 1), a batch record will have thousands of pieces of paper operators have checked, dated, and signed ensuring everything has been executed per the operating procedure.

Comments are closed.