Implementing The 5 Core Lean Principles Vrogue Co

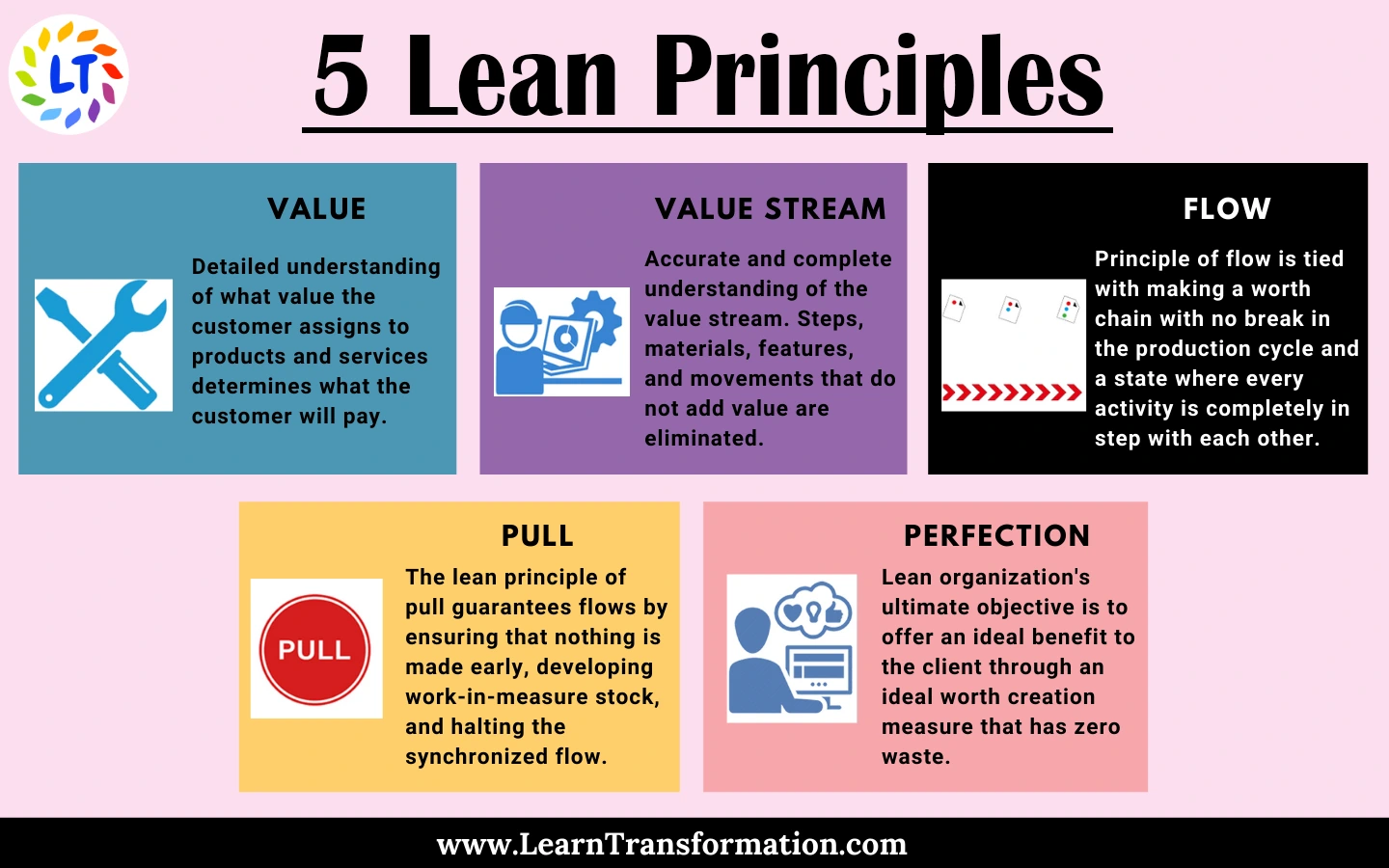

Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co The five principles of lean manufacturing – value, value stream, flow, pull, and perfection – provide a powerful framework for improving efficiency, reducing waste, and delivering superior value to customers. while each principle is important in its own right, they are most effective when implemented together as an integrated system. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles.

Implementing The 5 Core Lean Principles Vrogue Co Website. save my name, email, and website in this browser for the next time i comment. this site uses akismet to reduce spam. . the five principles of lean: value, value stream, flow, pull, and continuous improvement help eliminate waste and improve process efficiency. The lean principles originated from the toyota production system (tps), these principles are clear sets of guidelines and techniques aimed at improving processes, minimizing waste, and therefore resulting in an overall increase in customer value. the five principles of lean are: 1. to identify value, 2. mapping the value stream, 3. 5 fundamental principles in lean . the five pillars of lean manufacturing are fundamental principles that support this management philosophy, guiding organizations in implementing more efficient processes and eliminating waste. they form the foundation for value creation and continuous improvement within lean production. the five pillars are:. The 5 core principles of the lean manufacturing concept. the l ean manufacturing concept or lean production process is a structured framework based on five core principles that help you identify and eliminate waste, streamline processes, and continuously improve. let’s delve into each principle to understand how it can benefit your business.

Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co 5 fundamental principles in lean . the five pillars of lean manufacturing are fundamental principles that support this management philosophy, guiding organizations in implementing more efficient processes and eliminating waste. they form the foundation for value creation and continuous improvement within lean production. the five pillars are:. The 5 core principles of the lean manufacturing concept. the l ean manufacturing concept or lean production process is a structured framework based on five core principles that help you identify and eliminate waste, streamline processes, and continuously improve. let’s delve into each principle to understand how it can benefit your business. Respect for people: respect for people is a foundational principle of lean management, emphasizing the importance of valuing and empowering employees. it involves fostering a work environment that encourages collaboration, trust, and open communication among team members. implementing lean management principles often involves a phased approach. The five lean principles are: specify value, map the value stream, create flow, establish pull, and seek perfection. seeking perfection and making the most of lean principles takes time and ongoing company wide effort. a lean manufacturing consultant can provide expertise in developing lean strategies, optimizing workflows, developing new.

Five Lean Principles Project Management Templates Sof Vrogue Co Respect for people: respect for people is a foundational principle of lean management, emphasizing the importance of valuing and empowering employees. it involves fostering a work environment that encourages collaboration, trust, and open communication among team members. implementing lean management principles often involves a phased approach. The five lean principles are: specify value, map the value stream, create flow, establish pull, and seek perfection. seeking perfection and making the most of lean principles takes time and ongoing company wide effort. a lean manufacturing consultant can provide expertise in developing lean strategies, optimizing workflows, developing new.

Comments are closed.