Implementing The 5 Core Lean Principles

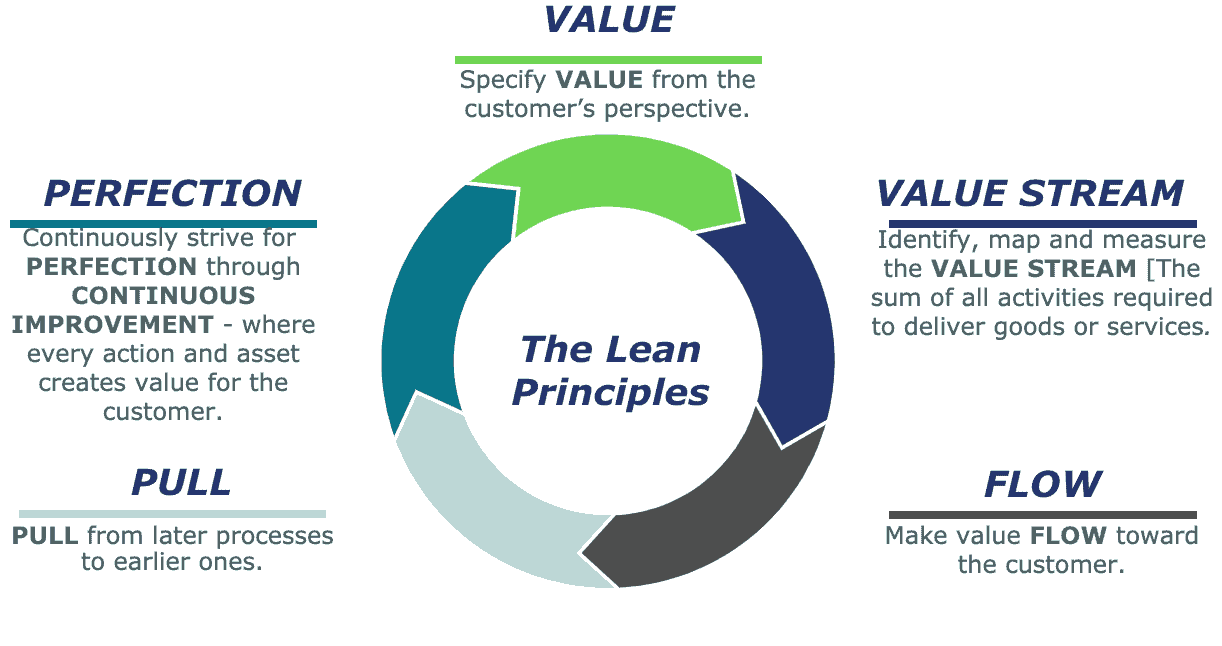

Implementing The 5 Core Lean Principles Youtube The five principles of lean manufacturing – value, value stream, flow, pull, and perfection – provide a powerful framework for improving efficiency, reducing waste, and delivering superior value to customers. while each principle is important in its own right, they are most effective when implemented together as an integrated system. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles.

The Five Principles Of Lean The lean principles originated from the toyota production system (tps), these principles are clear sets of guidelines and techniques aimed at improving processes, minimizing waste, and therefore resulting in an overall increase in customer value. the five principles of lean are: 1. to identify value, 2. mapping the value stream, 3. The five principles of lean. the five principles of lean are: specify value from the standpoint of the end customer. identify all the steps in the value stream, eliminating whenever possible those steps that do not create value. make the value creating steps occur in tight sequence so the product will flow smoothly toward the customer. Anastasia worked in management consulting and tech startups, so she has lots of experience in helping professionals choosing the right business software. the 5 principles of lean management include 1) define value, 2) map the value stream, 3) create flow, 4) establish pull, and 5) constant improvement. Waiting. non utilized talent. transportation. inventory. motion and extra processing. there is also the concept of lean enterprise, which expands the ideology to the entire value stream or supply chain. lean manufacturing and enterprise ideally work together to reach the fullest expression of the lean philosophy.

Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co Anastasia worked in management consulting and tech startups, so she has lots of experience in helping professionals choosing the right business software. the 5 principles of lean management include 1) define value, 2) map the value stream, 3) create flow, 4) establish pull, and 5) constant improvement. Waiting. non utilized talent. transportation. inventory. motion and extra processing. there is also the concept of lean enterprise, which expands the ideology to the entire value stream or supply chain. lean manufacturing and enterprise ideally work together to reach the fullest expression of the lean philosophy. Lean has proven to be an effective model for managing teams in some of the most demanding industries, like software development, manufacturing, construction, and many others. with its holistic approach encompassing five core principles value identification, value stream mapping, flow creation, pull system establishment, and relentless pursuit. The five lean principles are: specify value, map the value stream, create flow, establish pull, and seek perfection. seeking perfection and making the most of lean principles takes time and ongoing company wide effort. a lean manufacturing consultant can provide expertise in developing lean strategies, optimizing workflows, developing new.

Implementing The 5 Core Lean Principles Riset Lean has proven to be an effective model for managing teams in some of the most demanding industries, like software development, manufacturing, construction, and many others. with its holistic approach encompassing five core principles value identification, value stream mapping, flow creation, pull system establishment, and relentless pursuit. The five lean principles are: specify value, map the value stream, create flow, establish pull, and seek perfection. seeking perfection and making the most of lean principles takes time and ongoing company wide effort. a lean manufacturing consultant can provide expertise in developing lean strategies, optimizing workflows, developing new.

Comments are closed.