Hvac System Design Tutorial Calculate Static Pressure Air Velocity

Hvac System Design Tutorial Calculate Static Pressure Air Velocity This is 38th hvac system design tutorial for beginners. in this tutorial, we will: continue on the one storey office building example with a roof top unit s. The velocity pressure is the pressure component associated with the movement of air within a duct. consider a scenario where a fan is propelling air through a duct system; during this process, two distinct pressures come into play – velocity pressure and static pressure. the combination of these pressures is termed total pressure.

What Is Static Pressure In Hvac System Brief Explanation About Duct This is 39th hvac system design tutorial for beginners. in this tutorial, we will: continue on the one storey office building example with a roof top unit s. 1. every system and every fan is different. now we can better design, plan for, measure, and troubleshoot these systems. 2. perceived small changes can cause big unintended effects. 3. you don’t need to memorize the fundamentals to be successful in the hvac industry, but the more you know, the more valuable you can be to your customers. 0.01 = dspc s 0.10 or dspc s = 0.09 inches wg. the negative result indicates a static regain, or that the static pressure at point s will be 0.09 inches wg higher than the static pressure at point c. the loss coefficient data for reducers and straight throughs is found in the ashrae duct fitting database. To balance the system by design increase the air flow rate in section 1 to bring it up to the higher pressure loss of section 2. to correct the air flow rate for section 1 use the fan laws: q 1 new = q 1 old * (p t loss 1 new p t loss 1 old)1 2. q 1 new = 4000 * (1.192 1.165)1 2 = 4046 cfm.

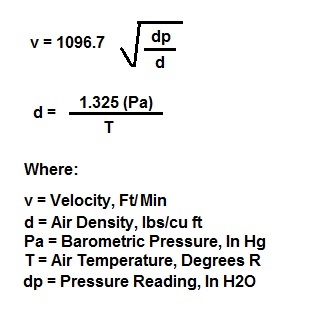

Use Static Pressure Responsibly Hvac School 0.01 = dspc s 0.10 or dspc s = 0.09 inches wg. the negative result indicates a static regain, or that the static pressure at point s will be 0.09 inches wg higher than the static pressure at point c. the loss coefficient data for reducers and straight throughs is found in the ashrae duct fitting database. To balance the system by design increase the air flow rate in section 1 to bring it up to the higher pressure loss of section 2. to correct the air flow rate for section 1 use the fan laws: q 1 new = q 1 old * (p t loss 1 new p t loss 1 old)1 2. q 1 new = 4000 * (1.192 1.165)1 2 = 4046 cfm. Insert the tubing: on one side, push the tubing onto a static pressure tip. the other end should connect to the gauge’s high pressure port. calibrate the gauge using the screw so the reading is zero. get a positive static pressure reading: insert the static pressure tip into the test port. the tip should face the airflow. Formula to calculate air velocity in a duct. to calculate air velocity in ducts, the following formula is used: where: – v = air velocity (m s or ft min) – q = airflow rate (m 3 s or cfm) – a = duct cross sectional area (m 2 or ft 2) for circular ducts, the area is calculated as a = π × r2, where r is the radius of the duct.

Basics Of Air Velocity Pressure And Flow Insert the tubing: on one side, push the tubing onto a static pressure tip. the other end should connect to the gauge’s high pressure port. calibrate the gauge using the screw so the reading is zero. get a positive static pressure reading: insert the static pressure tip into the test port. the tip should face the airflow. Formula to calculate air velocity in a duct. to calculate air velocity in ducts, the following formula is used: where: – v = air velocity (m s or ft min) – q = airflow rate (m 3 s or cfm) – a = duct cross sectional area (m 2 or ft 2) for circular ducts, the area is calculated as a = π × r2, where r is the radius of the duct.

Hvac System Design Tutorial Static Pressure Calculation In

Comments are closed.