How Smart Factories Benefit From Digital Twins Vrogue Co

How Smart Factories Benefit From Digital Twins Vrogue Co How smart factories benefit from digital twins today, the term digital twin is ubiquitous four years ago, i had my first personal contact with this concept. i attended the vdi conference “big data in manufacturing”, where a general electric’s (ge) manager presented the well known example of the transformation of ge’s business model in the aircraft turbine market. Delivering value in the factory environment. factory digital twins are unlocking value in all kinds of industries and use cases. a factory digital twin developed and deployed for an industrials player was recently used to redesign the production schedule, compressing overtime requirements at an assembly plant and resulting in a 5 to 7 percent monthly cost saving.

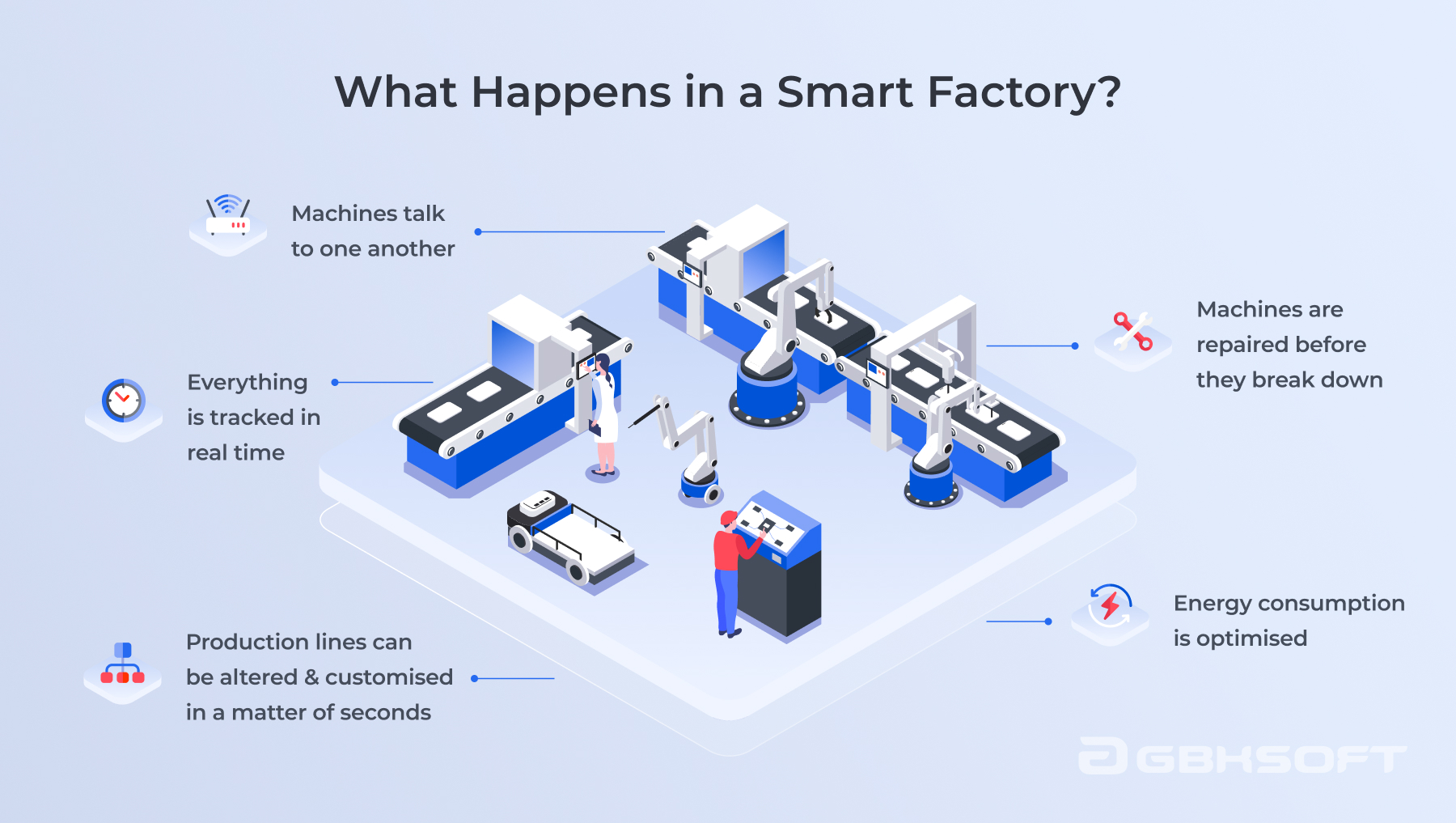

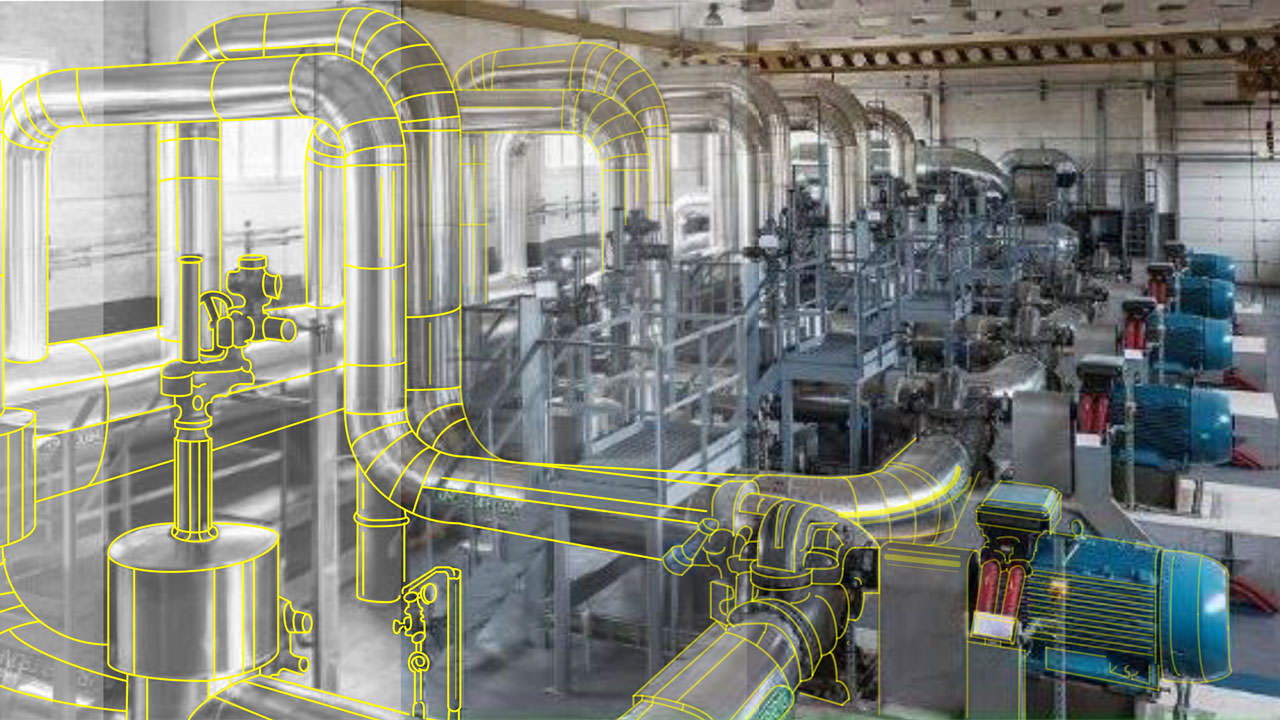

How Smart Factories Benefit From Digital Twins Vrogue Co A digital twin is a near real time representation of the physical attributes of a factory, product, or process. through connecting objects generating real time data, a digital footprint of a product, from design to production can be developed. data can be processed and aggregated based on a range of criteria and presented in various forms. Digital twins can also help optimize factory floor configurations, decrease downtime, and give you a deeper understanding of the physical assets that you manage. here are the top five examples of digital twin benefits in manufacturing: immersive, low risk training. dimensionally accurate space planning. intuitively locating maintenance and. Research shows the global digital twin market share is predicted to witness a staggering 31.9% cagr between 2020 and 2030 (forecast period), and the revenue generated in the industry would see a raise from $3.6 billion in 2019 to $73.2 billion by 2030. (1). In the smart factories that came with industry 4.0, digital twins of manufacturing processes are key to improving process robustness, development lead times and ultimately reducing costs. in this blog evan claes and tommy heck from our partner antleron explain how digital twins work and why they are so vital, especially to atmp manufacturing.

What Is A Smart Factory And Its Role In Manufacturing Vrogue Co Research shows the global digital twin market share is predicted to witness a staggering 31.9% cagr between 2020 and 2030 (forecast period), and the revenue generated in the industry would see a raise from $3.6 billion in 2019 to $73.2 billion by 2030. (1). In the smart factories that came with industry 4.0, digital twins of manufacturing processes are key to improving process robustness, development lead times and ultimately reducing costs. in this blog evan claes and tommy heck from our partner antleron explain how digital twins work and why they are so vital, especially to atmp manufacturing. The environment being simulated is recurring. digital twins are built to be used and reused, to repeatedly simulate and optimize multivariable problems. if the objective is to solve for a one time optimization of a single variable, an optimization model would work better than a digital twin. if these requirements are met, a digital twin can. At the heart of the fourth industrial revolution (4ir), also known as industry 4.0, smart manufacturing is transforming modern manufacturing operations. the smart manufacturing market, predicted to grow from $223.6 billion to an impressive $985.5 billion by 2032, has led to an increased prevalence of smart factories and smart warehouses alike.

How Smart Factories Benefit From Digital Twins Vrogue Co The environment being simulated is recurring. digital twins are built to be used and reused, to repeatedly simulate and optimize multivariable problems. if the objective is to solve for a one time optimization of a single variable, an optimization model would work better than a digital twin. if these requirements are met, a digital twin can. At the heart of the fourth industrial revolution (4ir), also known as industry 4.0, smart manufacturing is transforming modern manufacturing operations. the smart manufacturing market, predicted to grow from $223.6 billion to an impressive $985.5 billion by 2032, has led to an increased prevalence of smart factories and smart warehouses alike.

How Smart Factories Benefit From Digital Twins Vrogue Co

Comments are closed.