Hoisting Safety Guidelines At Josephine Tucker Blog

Hoisting Safety Guidelines At Josephine Tucker Blog Study with quizlet and memorize flashcards containing terms like a ? is one complete set of hoisting actions performed by workers who transport a load from a starting point to a destination., the largest types of cranes are typically used for the maintenance industries., the cranes and hoists involved in ? operations are typically permanently installed, and many are indoors. and more. Before going in on a project, you will need to know the load weight, the capacity of the hoisting machine and the working load limit of the rope, sling and hardware. 3. understand outrigger positions. always inspect machines, analyze the ground conditions and take care of deflection levels before hoisting and rigging.

Hoisting Safety Guidelines At Josephine Tucker Blog Just a quick check in each direction is sufficient for this portion of the inspection. there is no need for extreme movements. to check for proper operation, follow the steps below: first, you need to verify the markings on the pendant are correct – that “up” moves the hoist up and “down” moves the hoist down. Select the sling best suited for the job. *never tie knots in slings. *rigging equipment must not be loaded in excess of its safe working load. *hooks must be provided with safety latches. *know the limitations of the lifting device. *determine the center of gravity of the load. *protect sling from sharp surfaces. Carefully take up slack, confirming that the load’s balance, stability, and load holding action are secure before proceeding. under slack conditions, use hook latches to retain slings or chains. before operating the hoist, confirm that hook latches are closed and not supporting any parts of the load. avoid swinging the load or hook. Proper communication and coordination are essential for safe lifting in construction hoist operations. effective communication ensures that all workers involved in the lifting operation are aware of their roles and responsibilities, and are able to communicate any potential hazards or issues. coordination is important to ensure that all workers.

Hoisting Safety Guidelines At Josephine Tucker Blog Carefully take up slack, confirming that the load’s balance, stability, and load holding action are secure before proceeding. under slack conditions, use hook latches to retain slings or chains. before operating the hoist, confirm that hook latches are closed and not supporting any parts of the load. avoid swinging the load or hook. Proper communication and coordination are essential for safe lifting in construction hoist operations. effective communication ensures that all workers involved in the lifting operation are aware of their roles and responsibilities, and are able to communicate any potential hazards or issues. coordination is important to ensure that all workers. Operational safety inspections help identify pr oblems and addr ess them before an incident ma y occur, reducing risk for. personnel, your load, and y our lifting system. this guide co vers ever ything that operators should consider when per forming a pre operational hoist safety inspection. this guide will walk y ou through the following t. Equalize load on multiple leg slings. maintain load control. if required, attach tag lines prior to lift. keep personnel clear of lift area. lift load a few inches and check rigging. start and stop the lift slowly. watch for obstructions and power lines. maintain at least 10 feet from energized power lines at all times.

Hoisting Safety Guidelines At Josephine Tucker Blog Operational safety inspections help identify pr oblems and addr ess them before an incident ma y occur, reducing risk for. personnel, your load, and y our lifting system. this guide co vers ever ything that operators should consider when per forming a pre operational hoist safety inspection. this guide will walk y ou through the following t. Equalize load on multiple leg slings. maintain load control. if required, attach tag lines prior to lift. keep personnel clear of lift area. lift load a few inches and check rigging. start and stop the lift slowly. watch for obstructions and power lines. maintain at least 10 feet from energized power lines at all times.

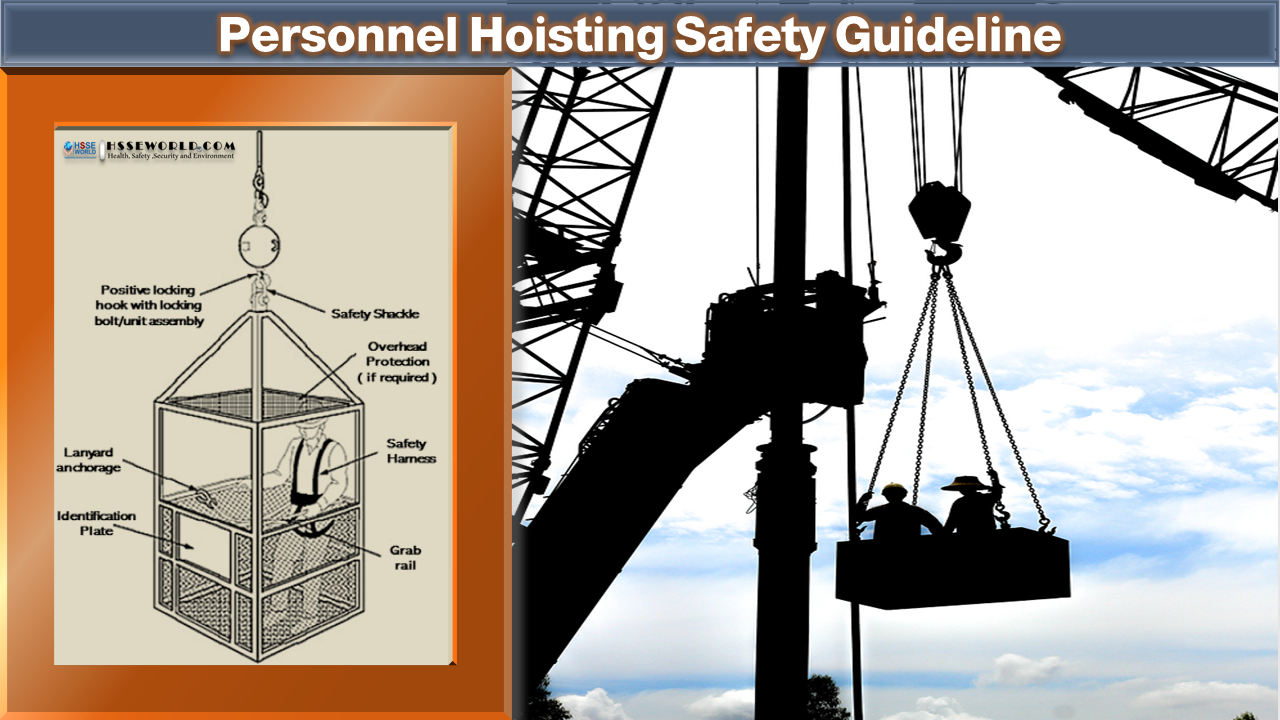

Personnel Hoisting Safety Guidelinehsse World

Comments are closed.