High Grade Continuous Centrifuges Broadbent Sugar

High Grade Continuous Centrifuges Broadbent Sugar The broadbent spvh high grade continuous centrifuge is designed to process high grade sugar massecuites for continuous performance with batch results. with design inspired and informed by the innovative technology of nqea and its partners in the australian sugar industry, our high grade continuous centrifuges offer a realistic alternative to batch centrifuges for specific products. The hgcc is significantly lower in cost than of typically 65%. there are also disadvantages with in operating table : 2 table 2 : hgcc disadvantages. typical new typical old 48”x30” requirement. high grade energy efficient batch centrifugal continuous centrifugal batch centrifugal. sugar moisture. 0.6 (%) ~ ~ 0.6. ~ 1.2.

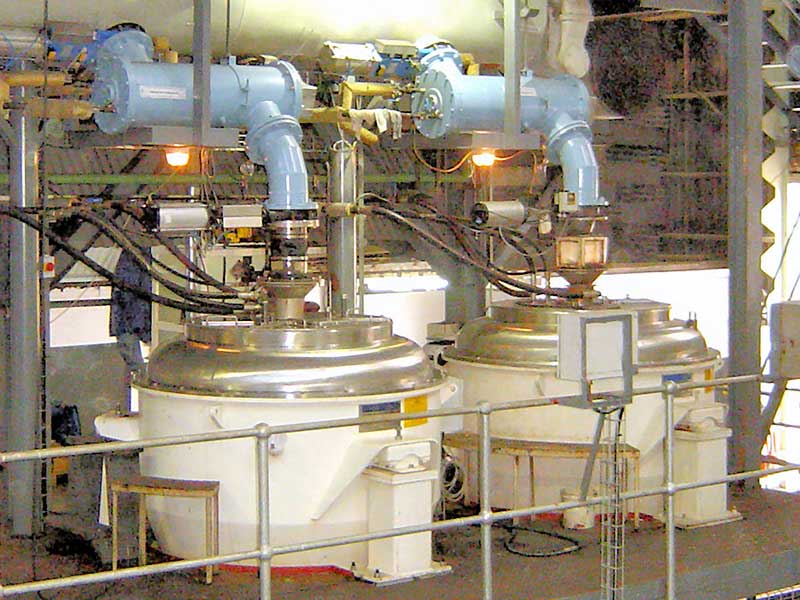

High Grade Continuous Centrifuges Broadbent Sugar Key benefits of broadbent sugar centrifuges. high capacity. high yield. efficient processing. improved operational efficiency and reliability. with batch centrifuge capacities up to 60 t h of massecuite and continuous centrifuge basket diameters up to 1.575m, broadbent has the solution for every sugar factory application. optional extras and. The broadbent spvh1100 high grade continuous centrifugal has the key features of our successful spv low & intermediate grade continuous centrifugals with special modifications for processing high grade sugars: stainless steel crystal protection equipment minimises crystal damage during discharge. a steep angled, fully perforated stainless steel. As a result broadbent sugar centrifugals are known for high capacity and efficient processing and are a major contributor to efficient and reliable factory operation. with batch centrifugal capacities up to 60 t h of massecuite and continuous centrifugal basket diameters up to 1.575m, broadbent has the solution for every application in a sugar factory. Power consumption for continuous high grade centrifugals has been quoted in the range of 0.5 to 0.8 kw.h t massecuite (greig et al., 1995; grimwood et al., 2000). data from the 2011 trials.

High Grade Continuous Centrifuges Broadbent Sugar As a result broadbent sugar centrifugals are known for high capacity and efficient processing and are a major contributor to efficient and reliable factory operation. with batch centrifugal capacities up to 60 t h of massecuite and continuous centrifugal basket diameters up to 1.575m, broadbent has the solution for every application in a sugar factory. Power consumption for continuous high grade centrifugals has been quoted in the range of 0.5 to 0.8 kw.h t massecuite (greig et al., 1995; grimwood et al., 2000). data from the 2011 trials. Evaluation of a high grade continuous centrifugal ' t. wong sak. engineering, materials science. 1996. the continuous centrifugal is made entirely of stainless steel, and is driven by an electric motor. it has a vertical shaft and a side feeding arrangement. the massecuite feed must be at 55°c…. expand. Broadbent manufactures batch and continuous centrifugals for sugar processing with optional features. their centrifugals are designed for ideal balance of capacity, process results, and sugar losses. key advantages include specially designed high performance motors, one piece shafts, and vibration tolerance. their high grade continuous centrifugal provides batch results with continuous.

Comments are closed.