Heat Exchanger For Marine Cooling System Hisakaworks

Heat Exchanger For Marine Cooling System Hisakaworks 1. seawater cooling system. the seawater is used as a cooling media in a heat exchanger to cool down the clean water and lubricating oil. 2. freshwater or central cooling system. freshwater is used in a closed circuit to cool down the engine room machinery. the freshwater returning from the heat exchanger after cooling the machinery is further. All right reserved. heat exchanger division at hisaka contributes the achievement of "energy saving, space saving, and highly efficient operation" for our customers' plants and equipment, through the manufacture and sales of plate heat exchangers for heating and cooling fluids, which is essential for any industrial process.

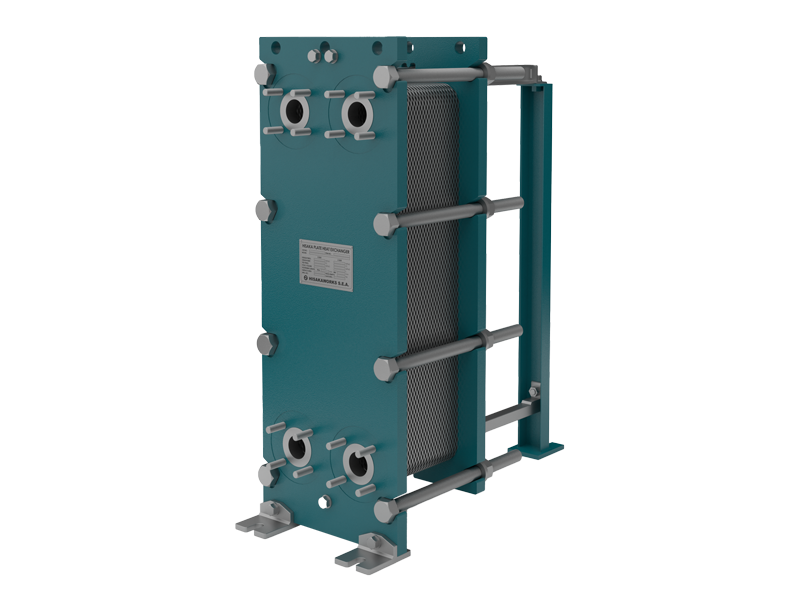

Heat Exchanger For Marine Cooling System Hisakaworks Heat exchanger division at hisaka contributes the achievement of "energy saving, space saving, and highly efficient operation" for our customers' plants and equipment, through the manufacture and sales of plate heat exchangers for heating and cooling fluids, which is essential for any industrial process. Hisaka cx series. 20 01 2022. the new cx series were designed with frames and nozzles that could match the connection of general plate heat exchangers in market. plus, the cx plate pattern provide equal heat transfer capability and able to handle operating condition of existing heat exchanger. download. For heat exchanger design & calculations. q1 = density x heat capacity x ( 1 2 ) x 3 3600 [kw] q2 = density x heat capacity x ( 5 4 ) x 6 3600 [kw] (for water, density is 1000, and heat capacity is 4.186kj kg deg.c.) the heat duty on hot side (q1) is equal to the heat duty on cold side (q2); q1 and q2 must be the same (q1 = q2). The orca marine cooling systems difference. designing a heat exchanger for marine engines requires close attention to related components, such as manifolds, cores, and tube stacks. this requires the ability to machine different tube sizes and materials while meeting tight tolerance ranges, all while maintaining a thorough understanding of how.

Heat Exchanger For Marine Cooling System Hisakaworks For heat exchanger design & calculations. q1 = density x heat capacity x ( 1 2 ) x 3 3600 [kw] q2 = density x heat capacity x ( 5 4 ) x 6 3600 [kw] (for water, density is 1000, and heat capacity is 4.186kj kg deg.c.) the heat duty on hot side (q1) is equal to the heat duty on cold side (q2); q1 and q2 must be the same (q1 = q2). The orca marine cooling systems difference. designing a heat exchanger for marine engines requires close attention to related components, such as manifolds, cores, and tube stacks. this requires the ability to machine different tube sizes and materials while meeting tight tolerance ranges, all while maintaining a thorough understanding of how. Hisa4 23 (philippines representative office) one global place, 20th floor, office business center, 25th street & 5th avenue, bonifacio global city, taguig 1632, philippines tel : 632 224 4129 fax : 632 224 4130 email : hisapino@hisaka asia . co219012015. Add to cart. 0509 103h7 marine power heat exchanger. $1,187.97. add to cart. 0565 1001 marine power heat exchanger. $1,355.00. add to cart. 0565 100p8 marine power heat exchanger. $1,801.24.

Comments are closed.