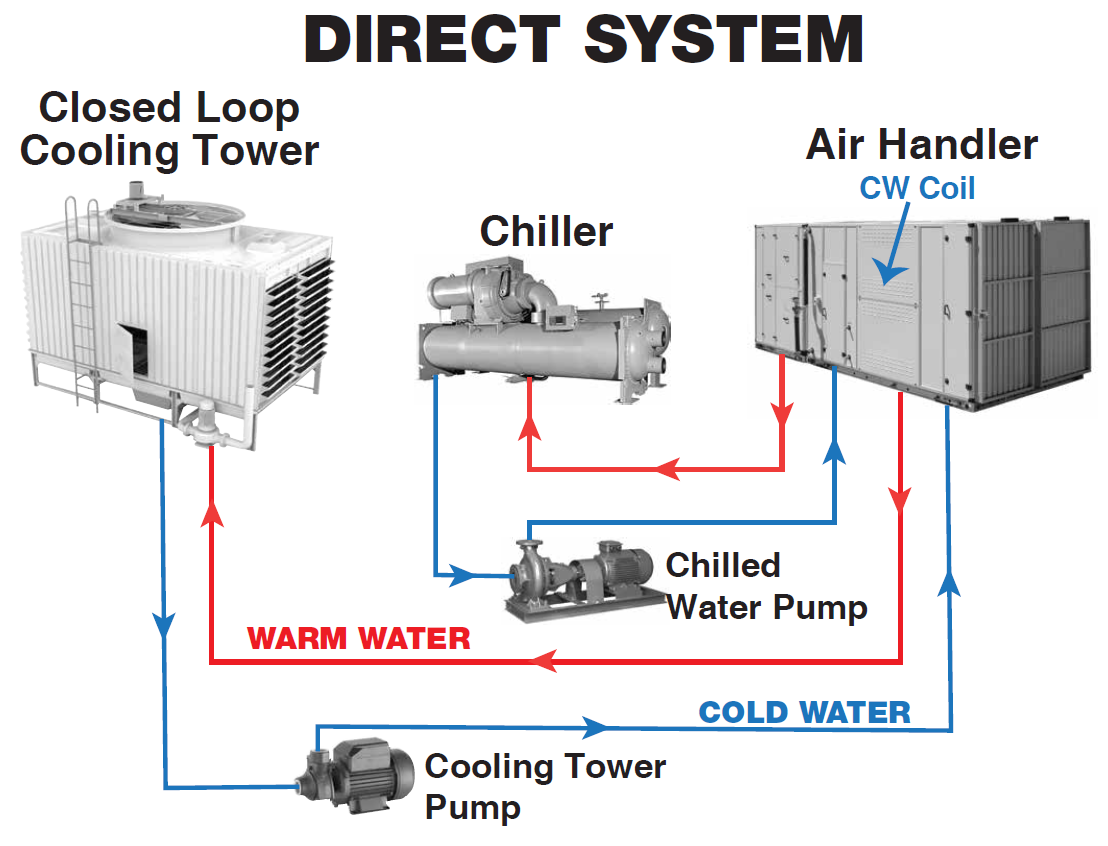

Flow Diagram Closed Loop Cooling

Closed Loop Cooling Tower Piping Schematic The closed recirculating cooling water system evolved from methods used for the cooling of early engine designs. in a closed water system, water circulates in a closed cycle and is subjected to alternate cooling and heating without air contact. heat, absorbed by the water in the closed system, is normally transferred by a water to water. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil.

What Is Closed Loop Cooling Troubles do occur occasionally, however, and these troubles can be classified as caused by: 1. incorrect pump head estimation. 2. pump cavitation and loss of pumping ability, as caused by inadequate pump suction pressure. 3. air in pump suction; as caused by tower pan vortex, pan drain down or faulty bypass. 4. Simple custom loop. this handy graphic breaks down the liquid cooling loop into its simplest form. starting at the bottom and moving clockwise, you’ll see that the reservoir feeds into the pump which then flows into the water block (s) followed by the radiator for exchanging heat with the surrounding air before finally completing the loop. Closed loop systems fluidflow. in general, there are two main types of systems in which pumps can be installed, open loop and closed loop systems. open loop systems are circuits in which the pumped fluid is exposed to the local atmosphere at some point in the circuit. a typical open loop system would be a cooling tower system where the. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil.

Understanding Closed Loop Cooling Water Systems Closed loop systems fluidflow. in general, there are two main types of systems in which pumps can be installed, open loop and closed loop systems. open loop systems are circuits in which the pumped fluid is exposed to the local atmosphere at some point in the circuit. a typical open loop system would be a cooling tower system where the. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil. Figure 1 1 closed loop fan speed control depending on the cooling medium temperature. the speed of the fan fans can be closed loop controlled based on the cooling medium temperature measured at the outlet. at low coolant temperatures only low airflow is required; the fan runs slowly and only blows air at a low rate. Industries. the range of wet & dry cooling solutions uses air, water or a combination of both as medium of heat rejection. this keeps the process fluid refrigerant properly cooled and increases the efficiency of production processes and operations of equipment. closed loop cooling tower warm air out warm air warm air cooled water out cold water.

What Is Closed Loop Cooling In Air Conditioners Ice Qube Figure 1 1 closed loop fan speed control depending on the cooling medium temperature. the speed of the fan fans can be closed loop controlled based on the cooling medium temperature measured at the outlet. at low coolant temperatures only low airflow is required; the fan runs slowly and only blows air at a low rate. Industries. the range of wet & dry cooling solutions uses air, water or a combination of both as medium of heat rejection. this keeps the process fluid refrigerant properly cooled and increases the efficiency of production processes and operations of equipment. closed loop cooling tower warm air out warm air warm air cooled water out cold water.

Comments are closed.