Flexible Manufacturing System Fms Explained

Flexible Manufacturing System Fms Explained A flexible manufacturing system (fms) is a method of production that prioritizes adaptability. it's a recognition of change as an inevitable part of manufacturing operations, both big and small. fms is designed to accommodate production changes without affecting the quality, budget, or production deadlines. Flexible manufacturing units. flexible manufacturing units (fmc) consist of 1 2 machining centers, industrial robots, cnc machine tools, and material transportation and storage equipment. they are adaptable and flexible for machining diverse products. an fmc can be considered as the smallest scale fms and represents the evolution of fms towards.

Flexible Manufacturing System Fms With Visual Components Youtube A flexible manufacturing system (fms) is the production method that helps make this happen, and it can cut down both on production times and the amount of resource required. the system is designed to adapt to changes like slight (or more significant) variations to a product, production volumes – or even the addition of entirely new products. A flexible manufacturing system (fms) is designed up front to be readily adapted to changes in the type and quantity of goods being produced. production in an fms is largely automated, reducing. A flexible manufacturing system (fms) is a highly automated, computer controlled system that can produce a variety of products. unlike traditional manufacturing systems, which are designed to produce large quantities of a single product, an fms can quickly adapt to produce different products with minimal downtime. this flexibility allows companies to respond rapidly to changes in […]. Flexible manufacturing systems (fms) are designed to allow manufacturers to make sudden changes to production plans. in contrast with mass production on a traditional production line, the goal is easy adaptation of a manufacturing process at any time. this can range from producing brand new products to modifying batch sizes to simply reordering.

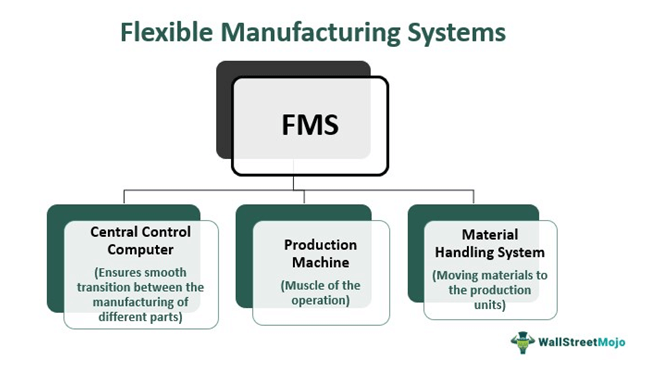

Flexible Manufacturing System Fms Featuring Six Modular Stations From A flexible manufacturing system (fms) is a highly automated, computer controlled system that can produce a variety of products. unlike traditional manufacturing systems, which are designed to produce large quantities of a single product, an fms can quickly adapt to produce different products with minimal downtime. this flexibility allows companies to respond rapidly to changes in […]. Flexible manufacturing systems (fms) are designed to allow manufacturers to make sudden changes to production plans. in contrast with mass production on a traditional production line, the goal is easy adaptation of a manufacturing process at any time. this can range from producing brand new products to modifying batch sizes to simply reordering. A flexible manufacturing system (fms) is a highly automated group technology (gt) machine cell consisting of a group of processing workstations interconnected by an automated material handling and storage system and controlled by a distributed computer system. it’s a collection of numerically controlled machine tools and supporting. A flexible manufacturing system (fms) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. this flexibility is generally considered to fall into two categories, which both contain numerous subcategories. the first category is called routing.

Flexible Manufacturing System Fms Festech A flexible manufacturing system (fms) is a highly automated group technology (gt) machine cell consisting of a group of processing workstations interconnected by an automated material handling and storage system and controlled by a distributed computer system. it’s a collection of numerically controlled machine tools and supporting. A flexible manufacturing system (fms) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. this flexibility is generally considered to fall into two categories, which both contain numerous subcategories. the first category is called routing.

Flexible Manufacturing System Definition Types Examples

Comments are closed.