Failure O Rings With Quality Issue Can Be Selected By Vision Inspection

Failure O Rings With Quality Issue Can Be Selected By Vision Inspection Possible o ring failure are happened during manufacturing process. analysis of the seal application is crucial to the understanding of possible o ring failure. understand the following common failure will help us better make a solution to visually inspect the defects by machine vision systems. gland design. O ring, sealing ring, washer, gasket, are common objects for product sealing. usually bad or failing o ring will produce a few symptoms and indicate a potential issue, such as fuel smell, liquid or gas leaking. therefore, to guarantee the quality of o rings, manufacturers choose to use machine vision inspection to replace human check.

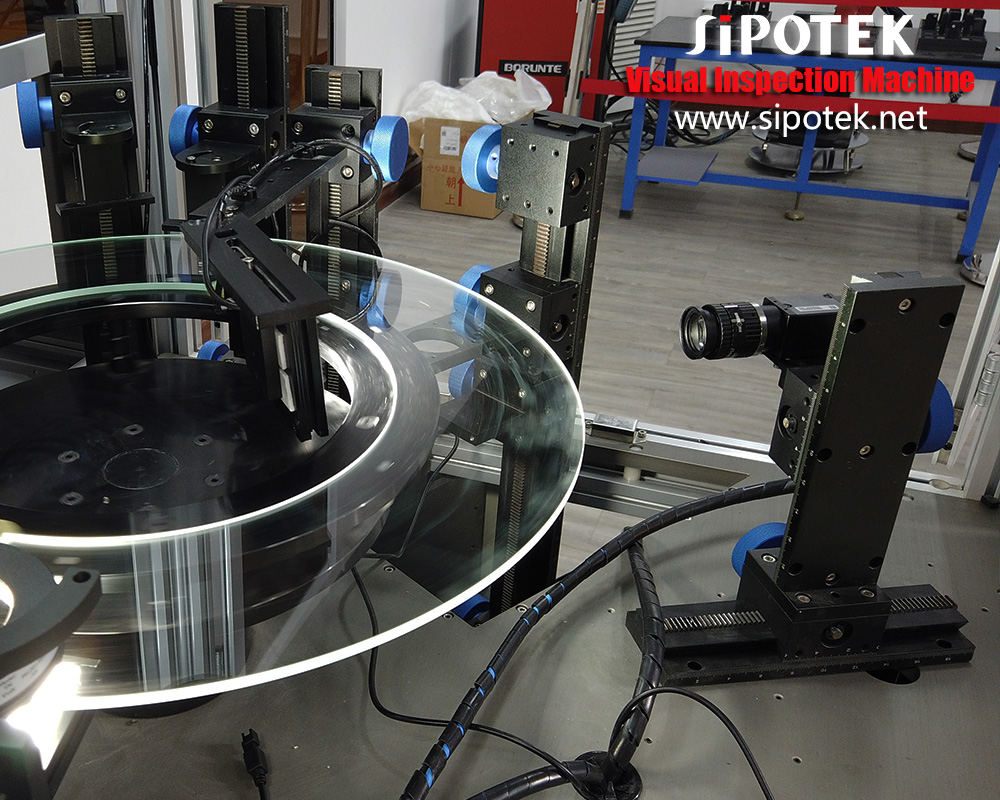

Failure O Rings With Quality Issue Can Be Selected By Vision Inspection They are very limited when it comes to testing a large amount of parts quickly and accurately. what is needed is an automated high speed vision inspection system that is tailor to made for the products. for example, o rings. the system should allow an operator to measure multiple o rings at the same time with same accuracy and with a fast speed. Precision measurement and inspection of o rings play a vital role in seal quality control. human inspection is a traditional way to remove defective o rings, which is instable and time consuming. the aim of this paper is to utilize the detection algorithms based on computer vision technology to control the quality of o rings, which includes the. Another setup using automated machine vision based photometric stereo inspection for o ring shaped pieces was developed by yang et al. which can detect manufacturing defects and scratches in the collected dataset based on a 2d images with different light orientations (iso 3601–3:2005) in order to measure inner and outer diameter accurately. A machine vision system is implemented analyze the captured images of o rings and perform the measurement and inspection processes. the proposed system is evaluated by inspecting a series of o rings.

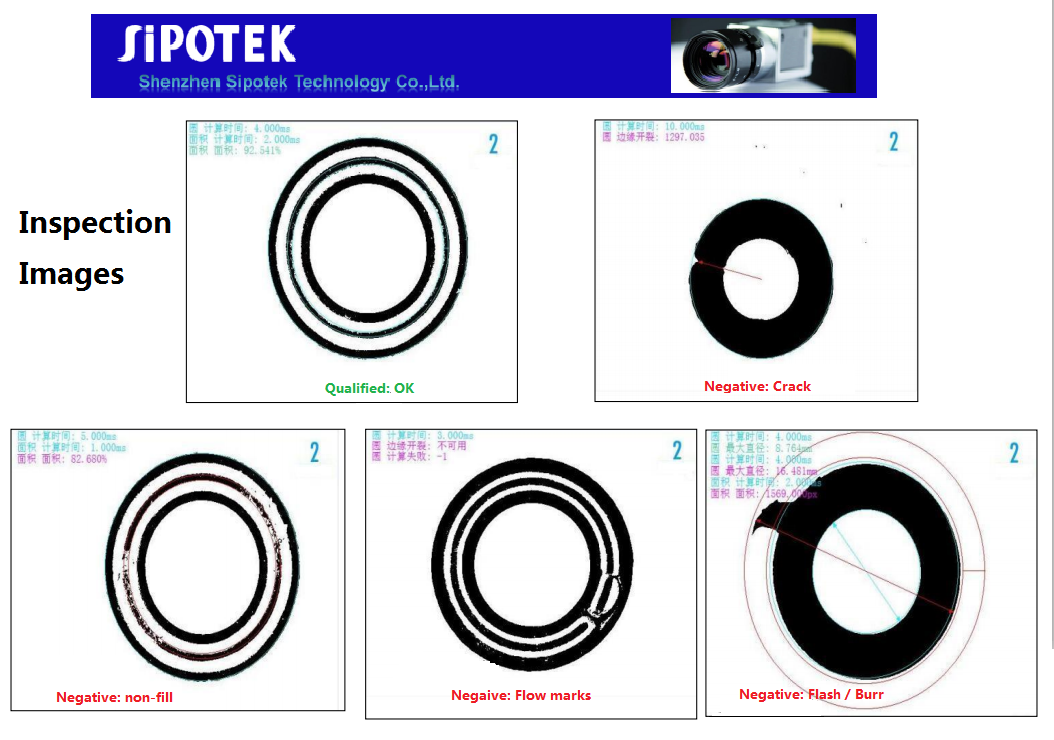

How To Find O Ring Defects By An Camera System Vision Inspection Another setup using automated machine vision based photometric stereo inspection for o ring shaped pieces was developed by yang et al. which can detect manufacturing defects and scratches in the collected dataset based on a 2d images with different light orientations (iso 3601–3:2005) in order to measure inner and outer diameter accurately. A machine vision system is implemented analyze the captured images of o rings and perform the measurement and inspection processes. the proposed system is evaluated by inspecting a series of o rings. A machine vision system is implemented analyze the captured images of o rings and perform the measurement and inspection processes. the proposed system is evaluated by inspecting a series of o rings. experimental results show that the proposed vision system is capable for measuring and inspecting o rings seal with good accuracy and efficiency. This research developed an aoi (automated optical inspection) system for the o ring inspection. first, an aoi system was implemented to detect surface scratches, flow marks, non fills, and indentations on elastomer o rings with high surface reflection coefficients. the proposed system employed multiple light source structures to realize the photometric stereo. this method eased the.

Machine Vision Inspection Scheme For O Ring Sipotek Visual Inspecti A machine vision system is implemented analyze the captured images of o rings and perform the measurement and inspection processes. the proposed system is evaluated by inspecting a series of o rings. experimental results show that the proposed vision system is capable for measuring and inspecting o rings seal with good accuracy and efficiency. This research developed an aoi (automated optical inspection) system for the o ring inspection. first, an aoi system was implemented to detect surface scratches, flow marks, non fills, and indentations on elastomer o rings with high surface reflection coefficients. the proposed system employed multiple light source structures to realize the photometric stereo. this method eased the.

Comments are closed.