Exact For Manufacturing No More Errors

Exact For Manufacturing No More Errors Youtube Manufacturers are under pressure. margins are small and there is no room for errors. how can you meet the high expectations of customers while remaining comp. Reducing manufacturing errors: the ultimate guide. manufacturing errors are potentially million dollar mistakes. according to a study of the top 72 multinational industrial manufacturers, the average cost of downtime was $532,000 an hour. and over the course of the year, these manufacturers lost $1 trillion in manufacturing failures.

(1500 × 1000 px).png?width=1440&name=Reduce Errors (1200 × 700 px) (1500 × 1000 px).png)

How To Efficiently Reduce Errors And Downtime In Manufacturing An all in one solution for your financial administration and logistics processes. exact for wholesale distribution's software provides a single system for your order and stock management, accounting and relationship management. prevent errors due to double entry and gain a real time view of your stocks, sales and margins. These problems can manifest as mechanical breakdowns, supply chain disruptions, quality control failures, process inefficiencies, or compliance challenges. each specific issue, whether it involves a single piece of malfunctioning equipment or a widespread breakdown in the supply chain, contributes to the broader category of manufacturing problems. 1. training & upskilling. leveraging ar solutions to solve manufacturing training and upskilling challenges benefits businesses and workers at all levels. digital ar work instructions scale to meet businesses where they are, whether they need to train at the individual, factory, or enterprise level. There are six main reasons why tolerances are important in manufacturing: 1. they improve the fit and functionality of parts: if you’re making parts that are compatible with other components, you absolutely have to define your tolerances. even a small mismeasurement or variation in size will make your product functionally useless or.

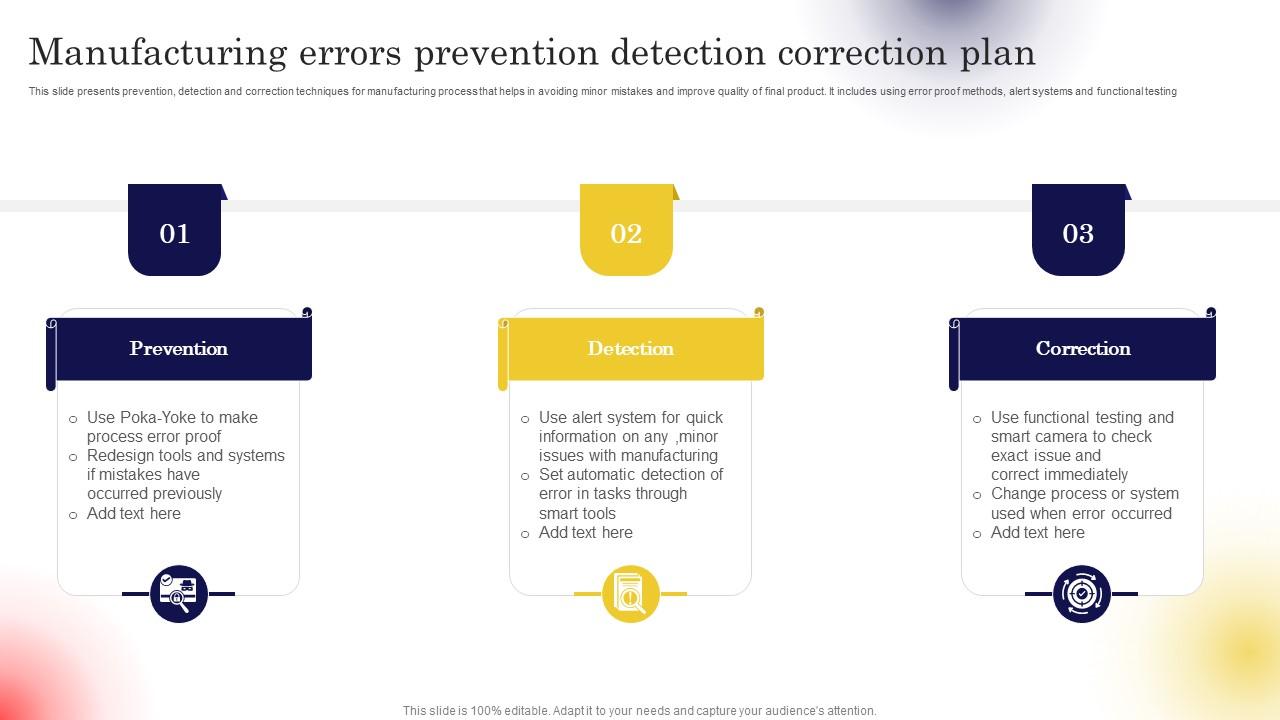

Manufacturing Errors Prevention Detection Correction Plan Ppt Slide 1. training & upskilling. leveraging ar solutions to solve manufacturing training and upskilling challenges benefits businesses and workers at all levels. digital ar work instructions scale to meet businesses where they are, whether they need to train at the individual, factory, or enterprise level. There are six main reasons why tolerances are important in manufacturing: 1. they improve the fit and functionality of parts: if you’re making parts that are compatible with other components, you absolutely have to define your tolerances. even a small mismeasurement or variation in size will make your product functionally useless or. Pdc550101en027.411 manual globe system (en).pdf: 6.0 mb: view: download. How do you eliminate manufacturing errors using lean techniques? powered by ai and the linkedin community. 1. identify the root causes. be the first to add your personal experience. 2. implement.

Best Practices Data Analytics Visualization In Manufacturing Pdc550101en027.411 manual globe system (en).pdf: 6.0 mb: view: download. How do you eliminate manufacturing errors using lean techniques? powered by ai and the linkedin community. 1. identify the root causes. be the first to add your personal experience. 2. implement.

Reducing Human Error In Manufacturing The Top Tips Miami Mca

Comments are closed.