Evapco Fluid Cooler Piping Diagram

Evapco Fluid Cooler Piping Diagram вђ Boredmonday Evapco provides a vast library of resources for our products. these tools are designed to access the unit information that you need. in documents, find catalogs and mechanical specifications, engineering bulletins, white papers, case studies and more. in drawings, find cad files, 3d models and more. to access evapco's collection of revit files. Visit evapco’s website at: evapco evapco, inc. — world headquarters & research development center evapco, inc. • p.o. box 1300 • westminster, md 21158 usa phone: 410 756 2600 • fax: 410 756 6450 • e mail: marketing@evapco evapco, inc. world headquarters p.o. box 1300 westminster, md 21158 usa phone: 410 756 2600 fax: 410.

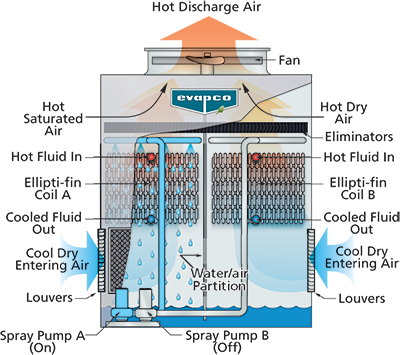

Eco Atwb E Closed Circuit Cooler Evapco Europe Steel pipe 1 1 2 inch (38mm) and smaller sch. 80, 2 inch (50mm) and larger sch. 40. r 717: 20°f ( 6.7°c) suction, 96.3°f (35.7°c) condensing. capacities based on line friction pressure drop per 100 feet (30m) of equivalent pipe length which corresponds to a 1°f (.5°c) change in saturation temperature. 5 at uat 1,2 m wide units. 6 at uat 2,4 and 2,6 m wide cells. download this manual. operation and maintenance instructions. for evapco induced draft and forced draft cooling towers. at. evapco, inc. (world headquarters) p.o. box 1300, westminster, maryland 21158 usa. evapco europe. bvba. The evaporative cooling unit cold water basin should be drained the cold water basin should be flushed and cleaned with the suction strainer screens in place . the suction strainer screens should be cleaned and re installed . page 12: fan system fan motor bearings evapco evaporative cooling units use either a t .e .a .o . All items attached to evapco closed circuit coolers or evaporative condensers must be independently reviewed and isolated to meet applicable wind and seismic loads. this includes piping, ductwork, conduit, and electrical connections.

Atwb Closed Circuit Cooler Evapco Australia The evaporative cooling unit cold water basin should be drained the cold water basin should be flushed and cleaned with the suction strainer screens in place . the suction strainer screens should be cleaned and re installed . page 12: fan system fan motor bearings evapco evaporative cooling units use either a t .e .a .o . All items attached to evapco closed circuit coolers or evaporative condensers must be independently reviewed and isolated to meet applicable wind and seismic loads. this includes piping, ductwork, conduit, and electrical connections. Cold weather operation evapco counterflow evaporative cooling equipment is well suited to operate in cold weather conditions. page 21: unit accessories “bypass” the towerʼs water distribution system as a means of capacity control. evapco recommends that the cooling tower bypass be installed in the condenser water piping system. Evapco east key building taneytown, md usa 410 756 2600 p marketing@evapco evapco midwest greenup, il usa 217 923 3431 p evapcomw@evapcomw evapco west madera, ca usa 559 673 2207 p contact@evapcowest evapco iowa lake view, ia usa 712 657 3223 p evapco iowa sales & engineering medford, mn usa 507 446 8005 p evapcomn@evapcomn.

Comments are closed.