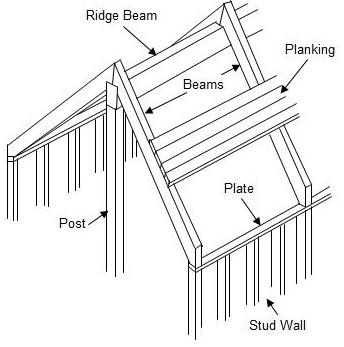

Diy Post And Beam Part 3 Insulated Roof And Pitch Transition Ase

Diy Post And Beam Part 3 Insulated Roof And Pitch Transition Ase Ive been building this diy post and beam building for almost 10 months. im starting to see the finish line on the horizon. heres how i designed and built a f. Position the transition flashing over the joint where the two differing roof pitches meet. the wider flange of the flashing should be placed over the higher pitch, overlapping the panel. this ensures water flows away from the transition area. secure the flashing using self drilling screws, spaced at intervals recommended by the manufacturer.

Building A House Diy Post And Beam Pt 3 Youtube Remove the roofing materials and install 4 8 inches of rigid foam insulation board above the roof decking, then new roof sheathing over that, then new roofing materials. build a metal roof (white or bare metal) over the existing shingle roof, using eave to ridge 2x4s to build ventilation channels under the new roofing. Any time an area of the roof changes pitch from peak to eave, you will need a transition trim to flash the area of panel break between the two pitches. a steeper pitch at the peak, with a lower pitch at the eave is called a lower gambrell condition. conversely a lower pitch at the peak and a steeper pitch at the eave is called an upper gambrell. By josh salinger issue 299 june 2021. synopsis: josh salinger’s design build firm made a commitment to avoid using plastic foam insulation above grade. but one of the toughest places to avoid foam is in the insulated roof assemblies of homes with vaulted ceilings. salinger describes his solution to avoiding plastic foam in these locations. Begin pre drilling your screw holes. at the edge of the top section of trim, pre drill a hole 1” inside and 2” from the edge on both sides of the trim. if overlaps are needed, don’t put a screw in the last 12” until overlap is done. prior to fastening the pitch break trim, place silicone sealant on top of the foam closures.

How To Design A Roof вђ Part 3 By josh salinger issue 299 june 2021. synopsis: josh salinger’s design build firm made a commitment to avoid using plastic foam insulation above grade. but one of the toughest places to avoid foam is in the insulated roof assemblies of homes with vaulted ceilings. salinger describes his solution to avoiding plastic foam in these locations. Begin pre drilling your screw holes. at the edge of the top section of trim, pre drill a hole 1” inside and 2” from the edge on both sides of the trim. if overlaps are needed, don’t put a screw in the last 12” until overlap is done. prior to fastening the pitch break trim, place silicone sealant on top of the foam closures. The new flashing should go under the old felt and over the new felt and new roll roofing. depends on the slope of the new roof. the lower the slope the further it should extend. roofing nails to the existing structural sheathing. the big idea is that layers of the lower roof should sit below corresponding layers of the upper roof. that is:. A roof pitch transition is a line in the roof plane that changes pitch. the roof plane goes from one pitch to a lower pitch. this is a fairly common roof detail. we see this quite frequently in log home roofs with porches, for example. see the illustration below. as you can see from illustration the roof changes pitch at the porch from a 9 12.

Comments are closed.