Digital Transformation In Manufacturing In 2023 8 Examples

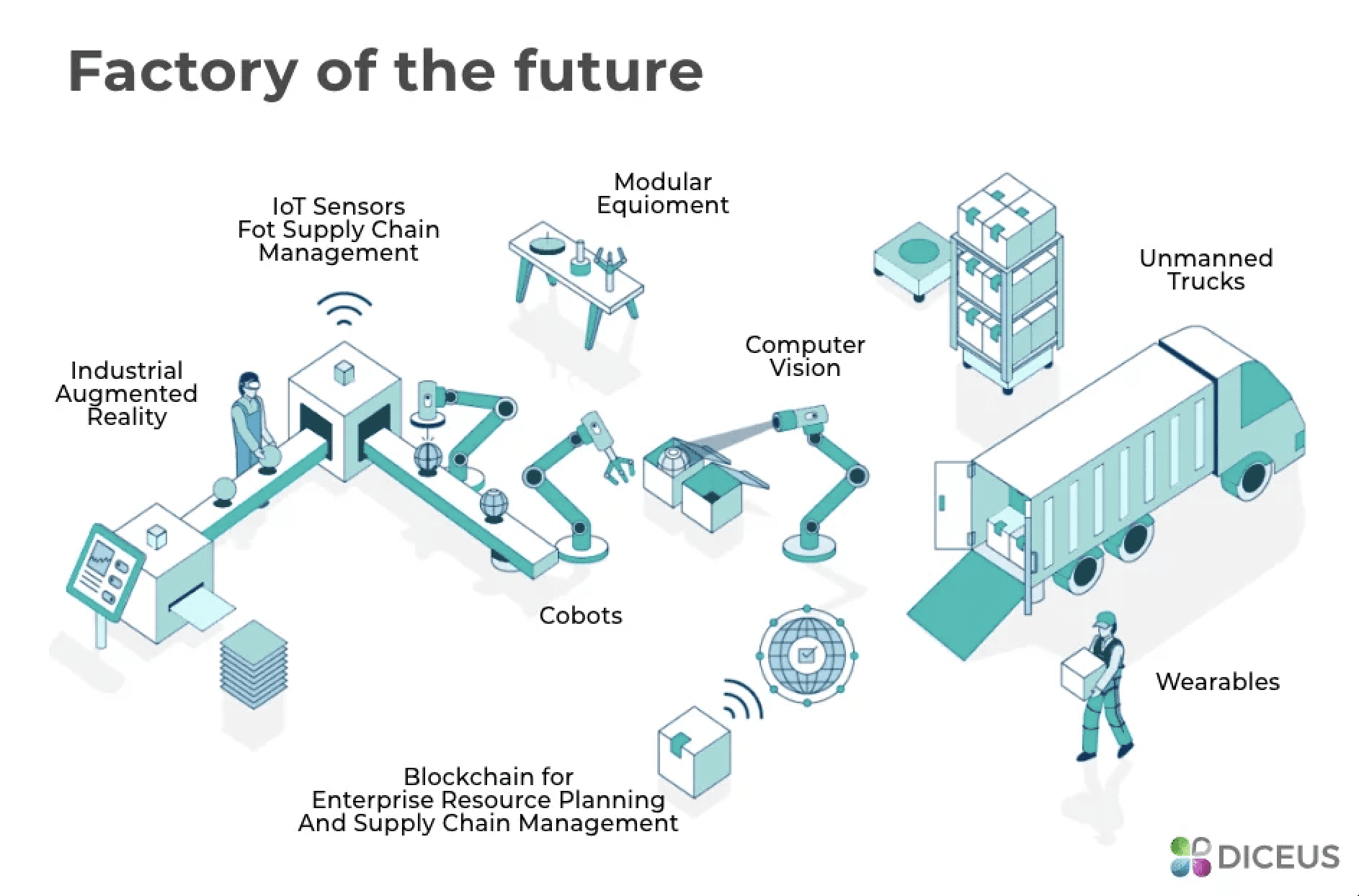

Digital Transformation In Manufacturing In 2023 8 Examples To help get manufacturing cios, ctos, and other leaders started with digital transformation in the manufacturing industry, here are nine examples of manufacturing digitalization: 1. industrial iot sensors. these devices measure and monitor industrial processes. Digital transformation is the process of replacing outdated systems and manual processes with digital technologies and tools to maximize employee productivity and improve overall business performance. digital transformation allows companies to: simplify and optimize processes. facilitate internal collaboration and communication.

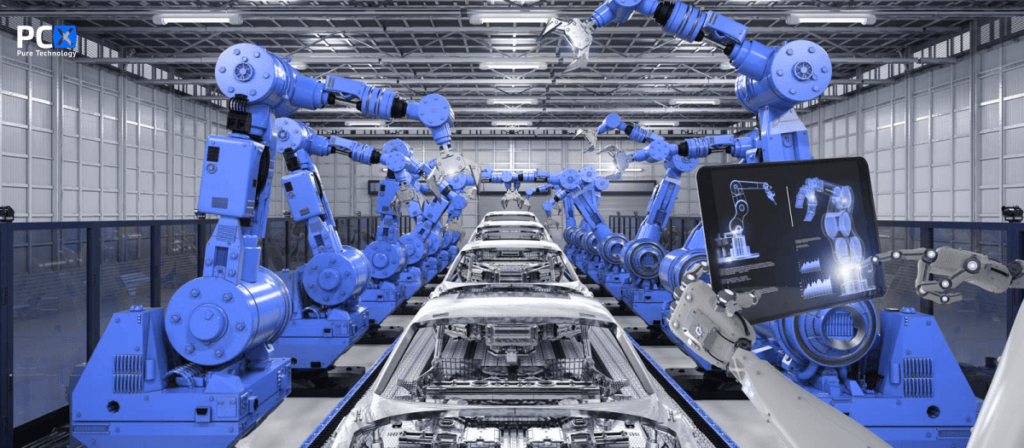

Digital Transformation In Manufacturing In 2023 Pure Technology In the past five years, a select group of companies have started pulling ahead in their efforts to implement industry 4.0 across their manufacturing networks. leading manufacturers are now realizing significant value from data and analytics, ai, and machine learning (ml). however, a large majority remain stuck in pilot purgatory, struggling to. And while the manufacturing industry trends are more traditional, this sector’s digital transformation moment is so big it has its own name, industry 4.0. according to one estimate, the market size for digital transformation in manufacturing is $307.87 billion as of 2023. more and more manufacturers are making the upfront investment in high. Proper data management and accessibility is the key to unlocking many advanced digital transformation efforts. 3. employee buy in. ptc data shows that the most successful digital transformations have both executive and employee buy in. employees at all levels need to feel a sense of project ownership. Understand manufacturing emerging technology priorities and progress by use case to identify some of the most adopted technology use cases to improve performance, and invest in “high importance,” “high deployment” technologies. by 2028, 80% of digital threads will start with plm, with increased investments to adapt plm as a digital.

Digital Transformation In Manufacturing In 2023 Pure Technology Proper data management and accessibility is the key to unlocking many advanced digital transformation efforts. 3. employee buy in. ptc data shows that the most successful digital transformations have both executive and employee buy in. employees at all levels need to feel a sense of project ownership. Understand manufacturing emerging technology priorities and progress by use case to identify some of the most adopted technology use cases to improve performance, and invest in “high importance,” “high deployment” technologies. by 2028, 80% of digital threads will start with plm, with increased investments to adapt plm as a digital. Manufacturing has undergone a major digital transformation in the last few years, with technological advancements, evolving consumer demands and the covid 19 pandemic serving as major catalysts for change. to maintain their competitiveness and overcome today’s challenges, manufacturers have had to make agility and adaptability top priorities. Key takeaways: the full article: as we approach the end of 2023, the manufacturing industry remains at the forefront of a digital transformation (dx) era. manufacturers are harnessing advanced manufacturing software solutions to create new avenues for continuous innovation, market growth, strategic success, and long term profitability. with 82%.

Digital Transformation In Manufacturing In 2023 8 Examples Manufacturing has undergone a major digital transformation in the last few years, with technological advancements, evolving consumer demands and the covid 19 pandemic serving as major catalysts for change. to maintain their competitiveness and overcome today’s challenges, manufacturers have had to make agility and adaptability top priorities. Key takeaways: the full article: as we approach the end of 2023, the manufacturing industry remains at the forefront of a digital transformation (dx) era. manufacturers are harnessing advanced manufacturing software solutions to create new avenues for continuous innovation, market growth, strategic success, and long term profitability. with 82%.

Comments are closed.