Cnc Standalone Controller Wiring And Operation Demonstration

Cnc Standalone Controller Wiring And Operation Demonstration Youtube In this video, i demonstrate a quick wiring of the ddcsv3.3 standalone cnc controller.product page: buildyourcnc item electronicsandmotors electro. This innovative controller is a game changer, eliminating the need for a computer and cnc interface. it connects effortlessly to four stepper motor drivers and stepper motors, streamlining your cnc setup. the package includes an intuitive control panel, a versatile pendant for axis movement at three different step increments, and a breakout board.

How To Wire A Cnc Controller The smc5 5 n n 5 axis motion controller is a standalone cnc axis controller without a pc that uses a high performance 32 bit cpu and high performance fpga, equipped with a 7 inch lcd, humanized window man machine interface, memory using an external usb port and a built in 8g tf card, can be connected to u disk, working voltage 12 24v ultra wide input, light touch operation keyboard. This is a fully functional controller, able to deliver 3.5 a to each stepper motor winding. right now dagu is in the prototype stage, but already there are some really interesting features: the. Since the cnc controller is not in the circuit switched by the contactor, the cnc controller will remain on when the e stop is pressed. if there is a power failure, the contactor disengages, so when the power comes back on, the machine stays off. if the machine would come back on when the power is restored, this would be a major safety hazard. The schematic of the grbl offline controller encompasses various electronic components that work together to control the cnc machine. the main components include microcontrollers, motor drivers, switches, connectors, power regulators, and other supporting elements. each element has a specific function in the overall functioning of the controller.

Ddcs V3 1 Cnc Controller Wiring Since the cnc controller is not in the circuit switched by the contactor, the cnc controller will remain on when the e stop is pressed. if there is a power failure, the contactor disengages, so when the power comes back on, the machine stays off. if the machine would come back on when the power is restored, this would be a major safety hazard. The schematic of the grbl offline controller encompasses various electronic components that work together to control the cnc machine. the main components include microcontrollers, motor drivers, switches, connectors, power regulators, and other supporting elements. each element has a specific function in the overall functioning of the controller. The ddcs expert is a 3~5 axis cnc motion controller for open or close stepper and servo systems with a 7 10.2 full color display screen. the highest output pulse per axis is 1mhz. the users can self define the functional keys. this cnc controller supports multiple spindle modes, support straight tool magazine, gantry type magazine, and disk. Step 1:centroid cnc pc minimum hardware and benchmark requirements for proper cnc control operation. verify that the pc intended for use with the acorn cnc controller meets the minimum performance requirements below. (note: the windows pc connected to the acorn board will be referred to as the “cncpc”).

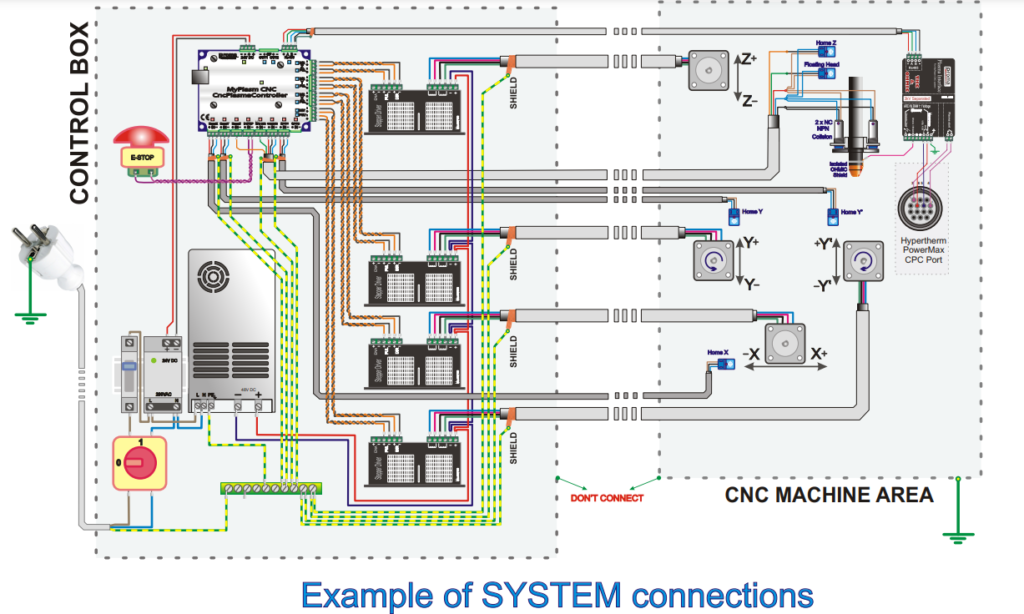

Myplasm Cnc Controller For Plasma Cutter Tables The ddcs expert is a 3~5 axis cnc motion controller for open or close stepper and servo systems with a 7 10.2 full color display screen. the highest output pulse per axis is 1mhz. the users can self define the functional keys. this cnc controller supports multiple spindle modes, support straight tool magazine, gantry type magazine, and disk. Step 1:centroid cnc pc minimum hardware and benchmark requirements for proper cnc control operation. verify that the pc intended for use with the acorn cnc controller meets the minimum performance requirements below. (note: the windows pc connected to the acorn board will be referred to as the “cncpc”).

Bsmce04u Cnc Controller Wiring

Comments are closed.