Cnc Machining Design Guide

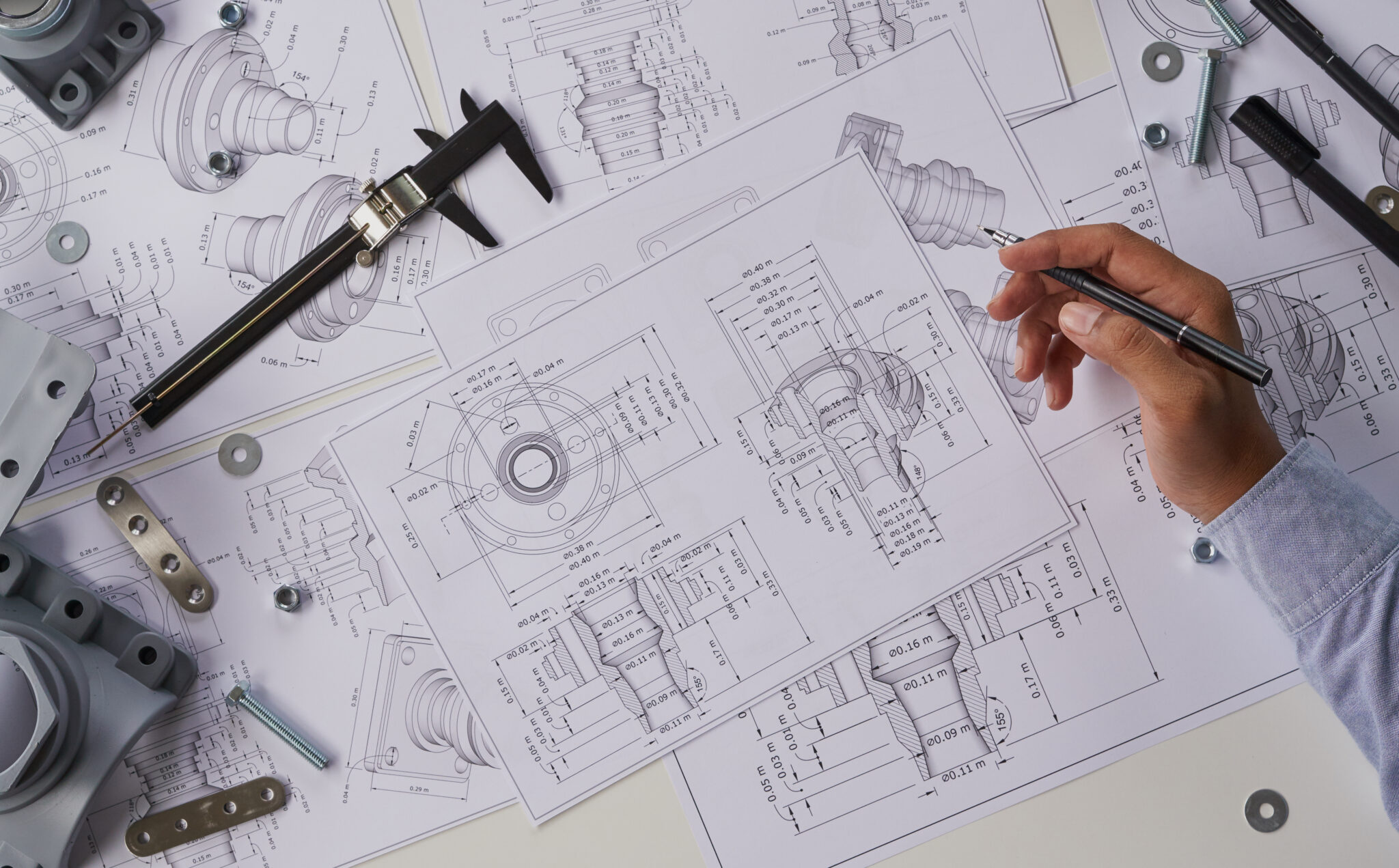

How To Prepare A Technical Drawing For Cnc Machining Step 1: export your design to a cnc compatible cad file format. the file formats predominantly used in cnc machining are step and iges. these formats are open source, standardized and can be used across platforms. for best results: export your designs directly from your native cad software into the step file format. Precision in cnc (computer numerical control) machining is essential for creating high quality components. the choices made during the design phase significantly impact the final product’s accuracy and functionality. material selection and geometric constraints are two critical factors that must be carefully considered to achieve optimal results.

Cnc Machining Center Provide Cad Fam Design Guide And Industry Cnc Material selection is an essential aspect of this cnc design guide as the cnc machining material’s properties will affect the machinability, cost, and overall quality of the finished part. metals furthermore, they have good machinability, heat, and corrosion resistance, and are highly versatile in producing components for different applications. Add the large fillets (at least ⅓ times the cavity depth) to all internal vertical corners. limit the depth of cavities to 4 times their width. align the main features of your design with one of the six principal directions. if that is not possible, 5 axis cnc machining is an option. In this downloadable guide, we’ve compiled eight common dfm considerations that should remain top of mind when designing parts for cnc machining. you can save significant time and cost by checking your design against this list before submitting it for manufacturing. top 8 design for manufacturing considerations for cnc machining 1. Protolabs is capable of machining text. here are our recommended text specifications for cnc milling: plastic and soft metals: minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). hard metals: minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). if the design permits it, opt for recessed vs. raised text.

Cnc Machining Design Guide Complete Guide 2023 In this downloadable guide, we’ve compiled eight common dfm considerations that should remain top of mind when designing parts for cnc machining. you can save significant time and cost by checking your design against this list before submitting it for manufacturing. top 8 design for manufacturing considerations for cnc machining 1. Protolabs is capable of machining text. here are our recommended text specifications for cnc milling: plastic and soft metals: minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). hard metals: minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). if the design permits it, opt for recessed vs. raised text. Get started with a dfm expert. designing for manufacturability accelerates the cnc machining process, reduces operating costs, elevates energy eficiency, and helps product teams create clean, functional parts. refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like fast. Design guide: cnc machining. with all of today’s innovative cnc machining capabilities, it’s important to understand the strengths and trade offs of this process. download our guide for cnc manufacturability recommendations to optimize your designs, reduce machining time, and lower your costs.

Comments are closed.