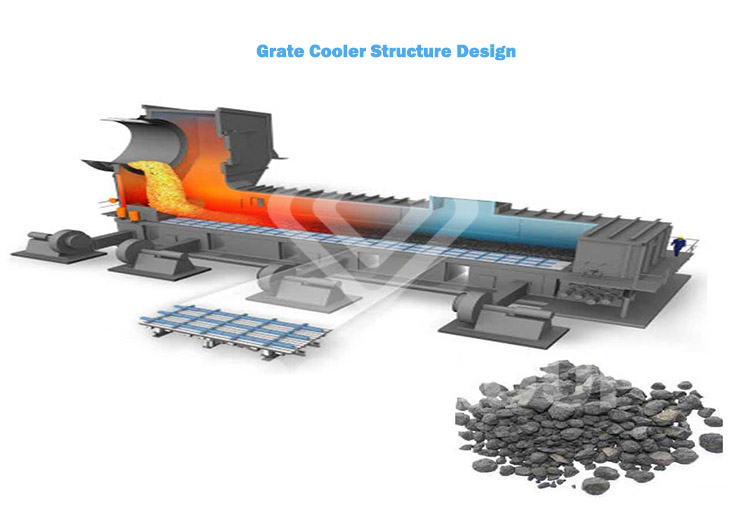

Clinker Cooler Grate And Beam Diagram

Grate Cooler вђ Clinker Cooler Agico Grate Cooler In Cement Plan The heat losses through radiation and sensible heat in clinker are between 0.40 and 0.45 mega joules per kilogram of clinker for an economical dry process kiln even and lower for wet process kilns. planetary coolers have been used successfully for kilns as big as 4000 metric tons per day, though not in north america. The clinker temperature is an important indicator of the grate cooler performance, which reflects the cooling efficiency of the grate cooler, and also creates conditions for the conveyer, storage, and cement grinding of clinker in subsequent processes. at present, the cooler manufacturer’s guaranteed value for this temperature is 65.

Clinker Rotary Kiln And Grate Cooler Download Scientific Diagram Role: reciprocating grate coolers are designed to cool the clinker by moving it through a series of grates in a reciprocating motion. this ensures efficient heat exchange and effective cooling. popular brands and models: estimated price: $500,000 – $1,500,000 depending on capacity and customization. The cooler grate is composed of overlapping rows of perforated grate plates. half of the rows are static, fixed to the casing of the cooler. the alternate rows are carried on a movable frame to which a reciprocating movement is imparted by an eccentric drive or hydraulic rams. the overlying bed of clinker is pushed forward on the forward stroke. The cement industry includes energy intensive processes, e.g., clinker rotary kilns and clinker grate coolers. clinker is obtained through chemical and physical reactions in a rotary kiln from raw meal; these reactions also involve combustion processes. the grate cooler is located downstream of the clinker rotary kiln with the purpose of suitably cooling the clinker. the clinker is cooled. To optimize the clinker cooling process. uncontrolled build up of clinker fines in the discharge outlets will considerably affect this cooling air flow and cause mechanical damage to cooler grates. to safeguard the grate system each fines discharge outlet is equipped with a capacitance high tempera ture point level probe. this level informa.

Clinker Grate Cooler For Cement Plant The cement industry includes energy intensive processes, e.g., clinker rotary kilns and clinker grate coolers. clinker is obtained through chemical and physical reactions in a rotary kiln from raw meal; these reactions also involve combustion processes. the grate cooler is located downstream of the clinker rotary kiln with the purpose of suitably cooling the clinker. the clinker is cooled. To optimize the clinker cooling process. uncontrolled build up of clinker fines in the discharge outlets will considerably affect this cooling air flow and cause mechanical damage to cooler grates. to safeguard the grate system each fines discharge outlet is equipped with a capacitance high tempera ture point level probe. this level informa. On a horizontal grate cooler the clinker bed when fluidized tends to remain stationary with more and more clinker building up on it. then when sufficient weight has been acquired by the bed and it starts to move again, there is so much clinker present in the cooler that it cannot be properly cooled, and it could again choke off air flow through. The grate upgrade kit of the polytrack® clinker cooler was designed specifically to address issues which are gaining importance for cement plant operators: electrical power consumption, maintainability and debottlenecking production capacities within an existing footprint, with only a fraction of the effort required to completely renew the.

3 Golden Rules For Clinker Cooler Infinity For Cement Equipment On a horizontal grate cooler the clinker bed when fluidized tends to remain stationary with more and more clinker building up on it. then when sufficient weight has been acquired by the bed and it starts to move again, there is so much clinker present in the cooler that it cannot be properly cooled, and it could again choke off air flow through. The grate upgrade kit of the polytrack® clinker cooler was designed specifically to address issues which are gaining importance for cement plant operators: electrical power consumption, maintainability and debottlenecking production capacities within an existing footprint, with only a fraction of the effort required to completely renew the.

Clinker Rotary Kiln And Grate Cooler Download Scientific Diagram

Comments are closed.