Chips For Control

Block Diagram Of The Control Chips For The Parts Engine Download 4 strategies for managing chip control. having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality. cutting tools. tooling. edited by: chris felix. former editor in chief, production machining. chip control issues can lead to shortened tool life, conveyor stoppages. The law provides the department of commerce with $50 billion for a suite of programs to strengthen and revitalize the u.s. position in semiconductor research, development, and manufacturing—while also investing in american workers. chips for america encompasses two offices responsible for implementing the law: the chips research and.

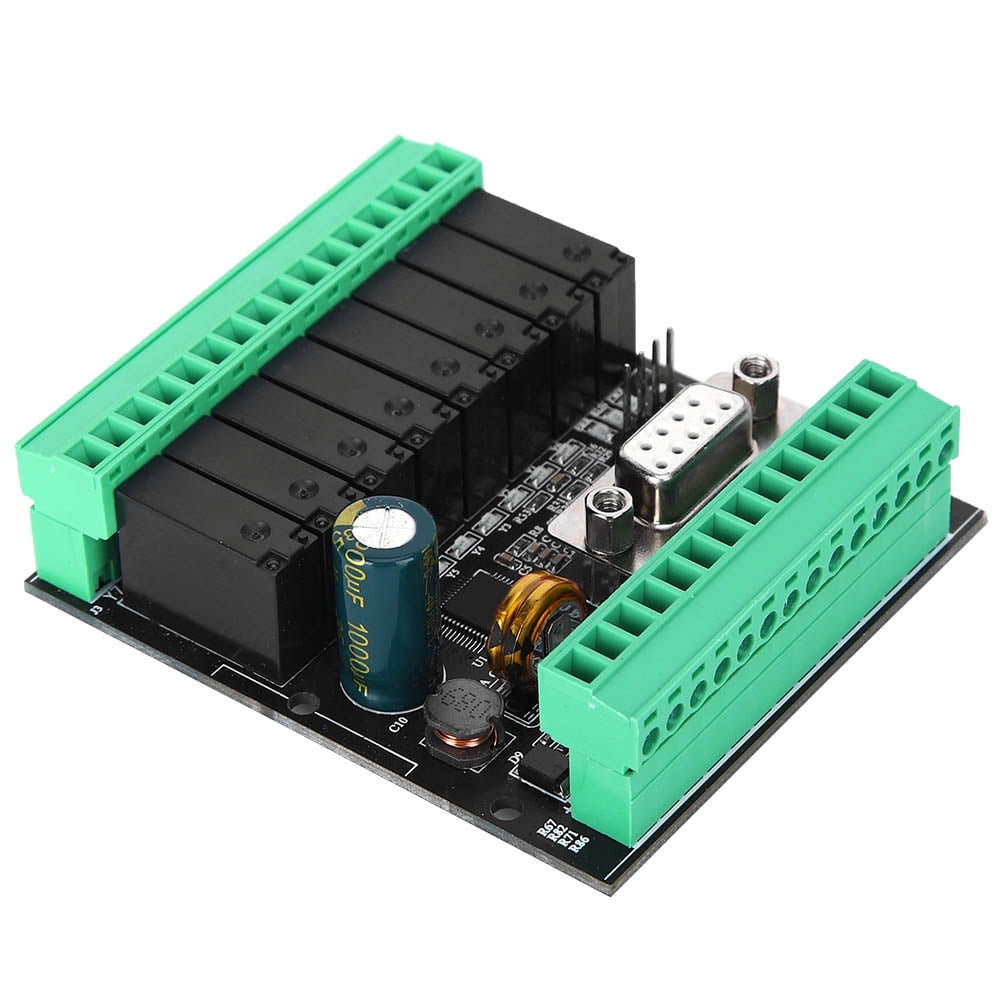

Industrial Control Board Professional Chips Plc Module 2 Channels For Keep an eye on chip formation. inspecting what comes out of the hole is just as important as inspecting the hole itself. take a look at your chips. as with other machining operations, ones shaped like cs and 9s are ideal, as are the tight conical chips formed by the center of a smoothly cutting drill. long, irregular chips, bird nests, or chips. Therefore, effective chip control is a crucial feature of all modern machining systems. the characteristics of formed chips depend on the type of machining material, ductile or brittle. on the other hand, machining process parameters also play an important role in the chip formation, namely, feed rate, rake angle, cutting speed, depth of cut. Motor control hardware and software solutions. our scalable motor control development tools enable rapid prototyping for low and high voltage systems, including dual motor control designs. you can use our free motor control software, application notes and tuning guides to simplify and speed up your development cycle. The control chip is implemented in 28 nm fully depleted silicon on insulator technology—a low power and low leakage cmos platform that is well suited for cryogenic operation 28,29,30 (further.

Comments are closed.